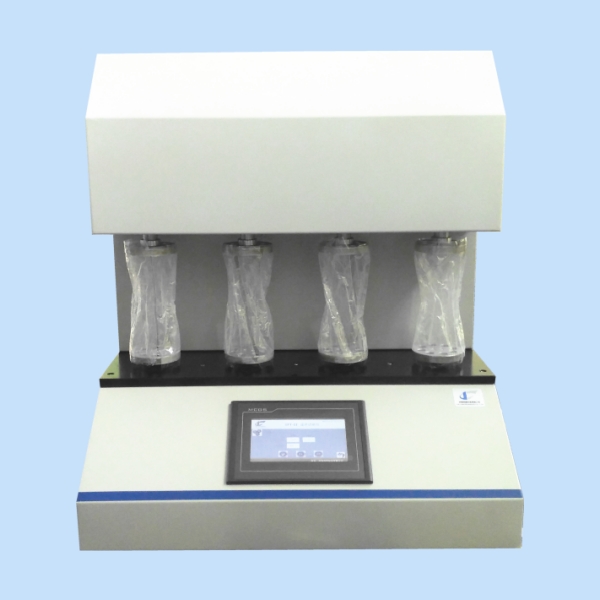

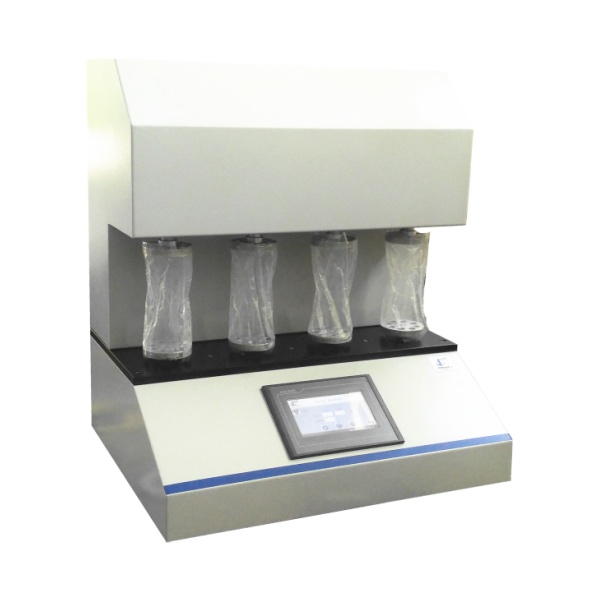

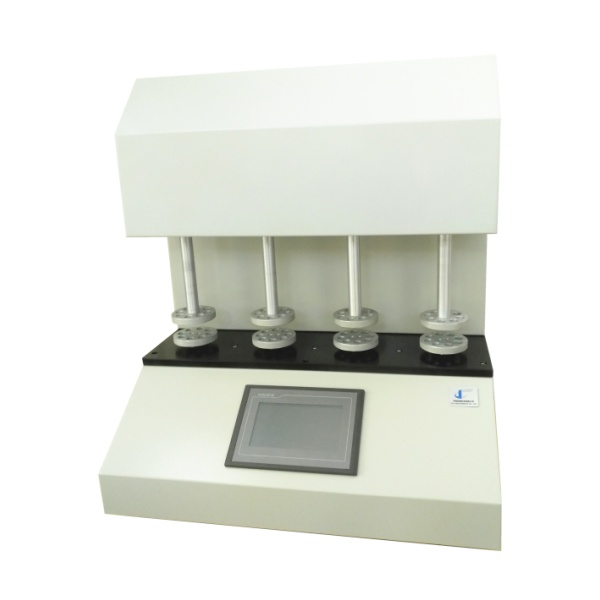

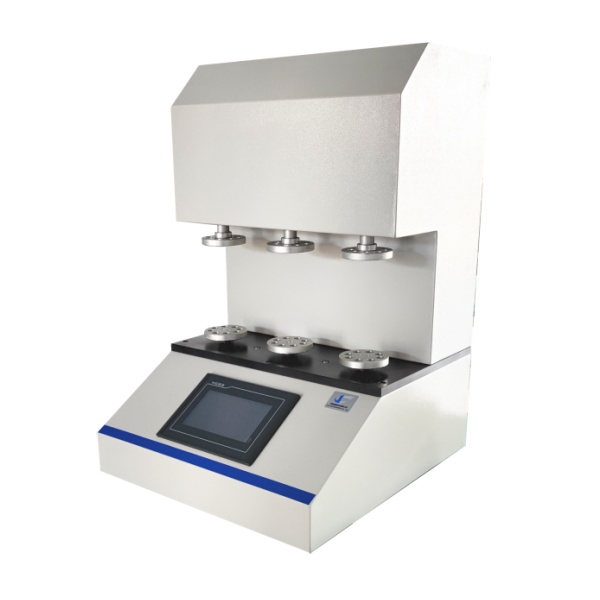

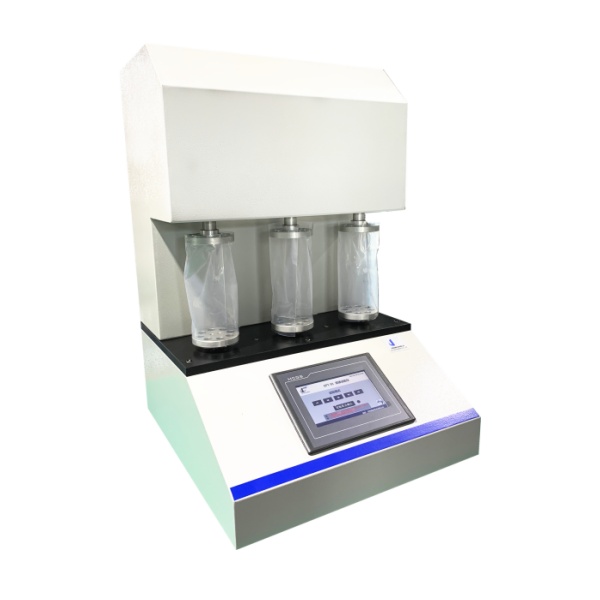

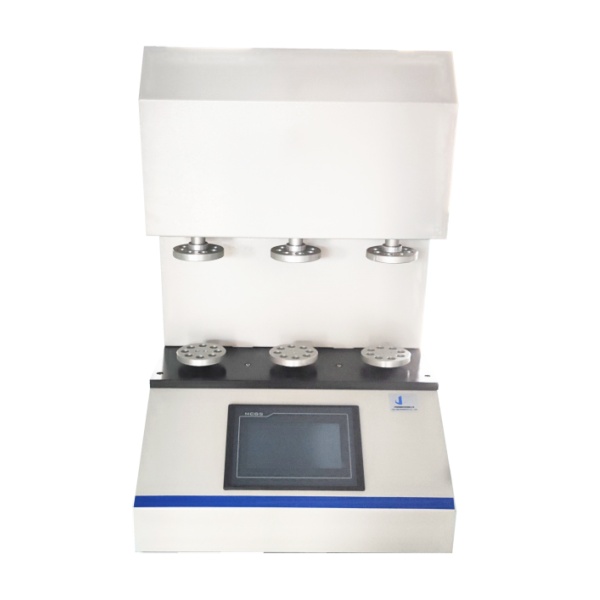

GFT Gelbo Flex tester

- Standard: ASTM F392

- Proizvođač: Cell Instruments

- Prijave: Ambalažni materijali, materijali za medicinske uređaje, farmaceutska ispitivanja, ljepila, tekstil, papirne i kartonske ambalaže i još mnogo toga.

- Prilagodba: Dostupno za posebne zahtjeve testiranja i transformacije automatizacije

Introduction of Gelbo Flex Tester

The Gelbo Flex tester is a specialized instrument designed to evaluate the flex durability and mechanical integrity of flexible materials such as barrier films, laminates, and coated fabrics. By simulating real-world twisting and compressive deformation, this tester provides critical insights into the resistance of packaging and coated materials to pinhole formation, cracking, i barrier property degradation. Standards such as ASTM F392 i ISO 7854 define the testing methods that ensure accuracy, repeatability, and international comparability.

The Gelbo Flex tester, sometimes referred to as a rumple flex tester ili flex tester, operates by subjecting test specimens to simultaneous twisting and compressing motions. This combined action reproduces the mechanical stress flexible packaging materials experience during filling, sealing, transportation, and storage.

The test method, commonly known as the Gelbo test method, evaluates a material’s ability to maintain integrity under cyclic deformation. Materials that fail this test often develop microscopic pinholes or cracks that compromise the package’s barrier performance against oxygen, moisture, or gas transmission.

Principle of the Gelbo Flex and Related Standards

Two primary international standards govern flex durability evaluation: ASTM F392 i ISO 7854.

ASTM F392, titled Standardna praksa za kondicioniranje fleksibilnih materijala barijere za fleksibilnu izdržljivost, specifies test conditions for assessing the resistance of flexible packaging materials to flex-induced pinholes and barrier failures. In this method, specimens undergo repeated flexing at 45 cycles per minute, involving a 440° twist combined with a 65 mm horizontal motion. The test is conducted under standard conditions of 23 ± 2°C i 50 ± 5% relative humidity. Depending on the desired conditioning level, test cycles may range from 20 to 2700, corresponding to levels A through E.

ISO 7854, Rubber- or plastics-coated fabrics — Determination of resistance to damage by flexing, defines three methods of flex testing. Method C, known as the crumple/flex method, closely resembles the Gelbo principle. Here, a cylindrical specimen is subjected to oscillating twist and axial compression, simulating real-life flex stress for coated fabrics, medical materials, and technical textiles.

Together, these standards establish the Gelbo flex procedure as the global benchmark for flex durability testing.

How the Gelbo Flex Tester Works

The Gelbo Flex tester (for example, the GFT Flex Durability Tester by Cell Instruments) operates with high precision to replicate ASTM and ISO flexing motions.

- Priprema uzorka: Standard samples are 200 × 280 mm, cut in both machine and transverse directions.

- Mounting: Samples are clamped or adhered to the tester’s mandrels, forming a cylindrical shape for simultaneous twisting and compression.

- Flexing Cycle: The tester executes a 440° twist during the first 90 mm of stroke, followed by a 65 mm linear compression, at a consistent 45 cycles per minute.

- Mode Selection: Users can select from five programmable test modes (A–E) to suit different material types or test objectives.

- Result Evaluation: After conditioning, specimens are inspected for pinholes, cracks, or barrier degradation using OTR (Oxygen Transmission Rate), WVTR (Water Vapor Transmission Rate), or GTR tests.

This controlled process allows laboratories and quality control teams to quantify a material’s flex resistance and predict its performance under real-world mechanical stress.

Key Features and Main Parameter

The GFT Gelbo Flex tester series from Cell Instruments offers advanced technology designed for high precision and ease of use:

- PLC Control & Touchscreen Interface – Ensures accurate motion control, user-friendly operation, and data repeatability.

- Multiple Test Stations – Available with three or four stations for parallel testing and comparative analysis.

- Programmable Test Conditions – Supports ASTM F392 modes A–E for versatile testing from quick screening (20 cycles) to endurance evaluation (2700 cycles).

- Durable Mechanical Design – Engineered for long-term stability and compliance with ASTM F392 i ISO 7854 standardima.

- Enhanced Data Reliability – Supports post-test evaluation of barrier integrity, pinhole formation, and mechanical strength changes.

| GFT Gelbo Flex Durability Tester | ||

| Parameter | GFT-02 Model | GFT-01 Model |

| Flex Angle | 440° (90 mm) ili 400° (80 mm) | |

| Kapacitet | 3.5 N.m | 2,5 Nm |

| Horizontal Stroke | 155 mm ili 80 mm | |

| Stanice | 3 | 4 |

| Veličina uzorka | 280 mm x 200 mm | |

| Snaga | 110~220V | |

Applications of Gelbo Flex Testing

Gelbo flex testing is essential in industries where flexible materials must retain barrier integrity and aesthetic quality after repeated handling or mechanical stress. Key application areas include:

- Flexible Packaging for food, pharmaceuticals, and medical devices

- Coated Fabrics and Films for industrial, textile, and outdoor uses

- Adhesive Laminates i composite structures

- Kontrola kvaliteta in R&D laboratories i certification agencies

By identifying weak points early, manufacturers can improve material formulation, coating technology, and lamination processes.

FAQs

O: Gelbo Flex tester kompanije Cell Instruments ima jedinstven spoj preciznog inženjeringa i inovativnih karakteristika dizajna. Od intuitivnog korisničkog sučelja do naprednih mogućnosti automatizacije, svaki aspekt je pomno osmišljen kako bi optimizirao performanse i korisničko iskustvo. Osim toga, njegova kompatibilnost u širokom rasponu materijala i industrija ga izdvaja kao svestrano rješenje za potrebe testiranja savitljivosti.

O: Podvrgavanjem materijala rigoroznom testiranju savitljivosti, tester izdržljivosti na savijanje pomaže da se identifikuju slabosti i potencijalne tačke kvara u ranoj fazi razvoja. Ovaj proaktivni pristup omogućava proizvođačima da riješe probleme prije nego što oni eskaliraju, što rezultira proizvodima koji su otporniji, pouzdaniji i na kraju boljeg kvaliteta.

O: Apsolutno! Gelbo Flex tester je dizajniran da prihvati širok raspon veličina i oblika uzoraka, nudeći fleksibilnost i svestranost u testiranju. Bilo da radite s malim, osjetljivim filmovima ili većim, glomaznijim materijalima, naš tester se može prilagoditi kako bi s lakoćom zadovoljio vaše specifične zahtjeve testiranja.

O: Preciznost je najvažnija kod testera savitljivosti. Kroz preciznu kalibraciju i robusnu konstrukciju, osiguravamo da svaki test daje dosljedne, pouzdane rezultate. Osim toga, naš tester je dizajniran da minimizira vanjske faktore koji mogu utjecati na rezultate testiranja, dodatno povećavajući točnost i ponovljivost.

O: U Cell Instruments-u prioritet su zadovoljstvo i podrška kupaca. Naš namenski tim za tehničku podršku je na raspolaganju da pomogne korisnicima sa svim pitanjima, nedoumicama ili tehničkim izazovima na koje se mogu susresti. Bilo da vam je potrebna pomoć pri postavljanju, kalibraciji ili rješavanju problema, naši stručnjaci su tu da pruže brzu i efikasnu podršku kako bi osigurali da vaši procesi testiranja teče glatko

Referenca

ASTM F392 Standardna praksa za kondicioniranje fleksibilnih materijala barijere za fleksibilnu izdržljivost