TAPPI T549

Friction Peel Tester Method

TAPPI T549 is a standardized testing method developed by the Technical Association of the Pulp and Paper Industry (TAPPI) to determine the coefficients of static and kinetic friction for uncoated printing and writing paper using a horizontal plane method. Understanding these coefficients is essential in paper manufacturing and converting industries, where paper-to-paper contact affects performance during feeding, stacking, and printing operations.

This method plays a pivotal role in assessing the surface characteristics of paper and supports quality control teams and professionals in achieving consistent performance. The accuracy and repeatability of the TAPPI T549 test method make it a widely accepted benchmark for paper coefficient of friction measurement.

Why Paper Coefficient of Friction Measurement Matters

Paper surfaces interact dynamically during production and application processes. The static COF measures the force required to initiate sliding between two sheets, while the kinetic COF refers to the force needed to maintain movement at a constant speed. A paper that is too slippery may lead to misfeeds, while a surface with excessive friction may cause tearing or jamming.

TAPPI T549 specifically addresses friction between two sheets of uncoated writing or printing paper, simulating conditions during stacking, feeding, or transporting of sheets through printers and copiers. Accurate paper coefficient of friction measurement helps in optimizing product formulations, evaluating coating effectiveness, and ensuring quality consistency across batches.

Standard Test Method Overview under TAPPI T549

The TAPPI T549 test involves a horizontal plane method, where a paper specimen is pulled across another sheet under controlled conditions. The setup includes:

- A smooth, level test plane (metal, glass, or plastic)

- A standardized sled with a compressible neoprene backing

- A force measuring device (like a load cell)

- A constant-speed motion system (typically 150 ± 30 mm/min)

The test is performed in both machine direction (MD) a cross-machine direction (CD) using carefully prepared specimens. Measurements capture the initial resistance (static COF) and sustained movement (kinetic COF).

TAPPI T549 differs from other methods like TAPPI T815, which measures the COF of packaging materials on an inclined plane. By focusing on flat sheet behavior and first-contact slips, T549 provides precise data for sheet-fed applications.

Sample Preparation and Test Procedure Essentials

According to TAPPI T549, meticulous sample preparation is crucial. Sheets must be:

- Preconditioned and conditioned per TAPPI T402

- Cut accurately to avoid edge damage (recommended sizes: 100×215 mm and 75×130 mm)

- Aligned in correct MD or CD orientations during testing

During testing, the sled must be gently placed without lateral movement. The pulling force is recorded immediately upon motion initiation (for static COF), and then averaged over a 130 mm travel for kinetic COF.

Care must be taken to avoid vibrations or stretch in the connecting wire, which can distort results. The FPT-01 addresses these challenges with stabilized construction and precision load sensing technology.

Applications and Business Value

Reliable COF data ensures consistent sheet feeding, better press efficiencya reduced product waste. For QA personnel and paper product developers, TAPPI T549 enables:

- Comparison of surface treatments (e.g., calendering, coating)

- Evaluation of batch uniformity

- Benchmarking against industry standards

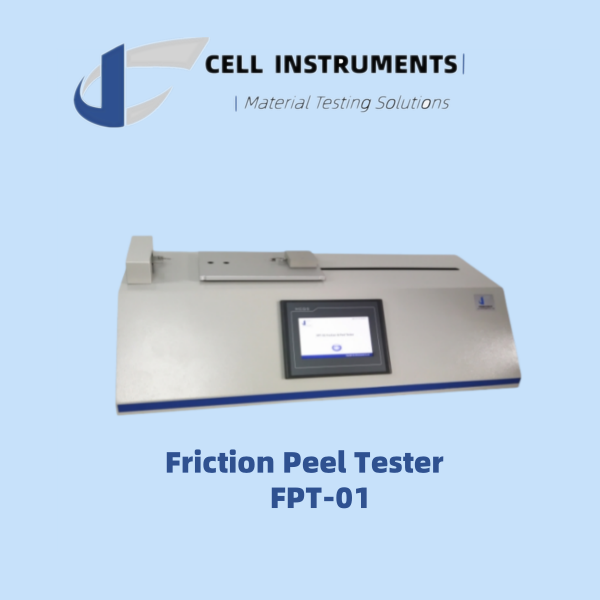

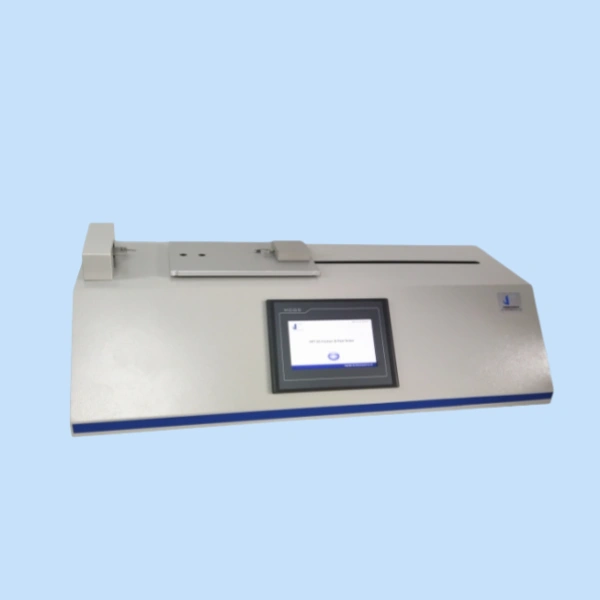

Choosing the Right Friction Peel Tester

To comply with TAPPI T549 and ensure high reproducibility, a robust and sensitive testing system is vital. The FPT-01 Friction Peel Tester from Cell Instruments is designed to meet these needs. It offers:

- High-precision force sensors with fast response rates

- Customizable sled mass and surface options compliant with TAPPI T549

- Uniform sliding speed control with minimal vibration

- Real-time data display and built-in COF calculations (static and kinetic)

- User-friendly software interface and optional data export functions

By using the FPT-01 cof tester, paper manufacturers and converters can confidently conduct paper coefficient of friction measurement aligned with TAPPI standards, minimizing manual error and enhancing lab throughput.

Contact Us Get TAPPI T549 D1709 Testing Solution

TAPPI T549 provides a critical benchmark for evaluating the static and kinetic friction of uncoated printing and writing paper. It enables manufacturers to fine-tune product performance, improve production efficiency, and meet end-user expectations. With Cell Instruments’ FPT-01 cof tester, organizations gain a reliable, standards-compliant solution for paper coefficient of friction measurement that ensures high accuracy and repeatability.

By integrating Buněčné nástroje‘ FPT-01 Friction Peel Tester, laboratories gain a dependable platform to implement TAPPI T549 accurately and efficiently, making it ideal for use in R&D labs, quality control departments, and third-party testing agencies.