The kompresní tester s krátkým rozpětím is an essential instrument in the paper and packaging industries, specifically designed to evaluate the compressive strength of paper and board materials. By simulating real-world compression forces, this tester helps manufacturers assess the ability of paper products to withstand pressure during handling, stacking, and transportation.

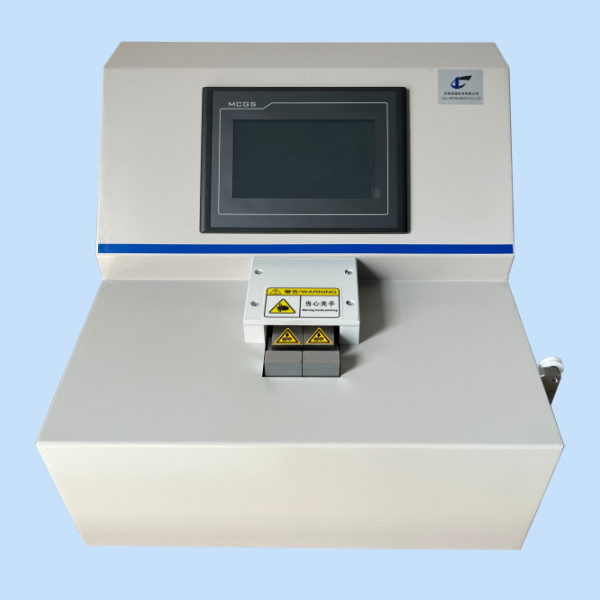

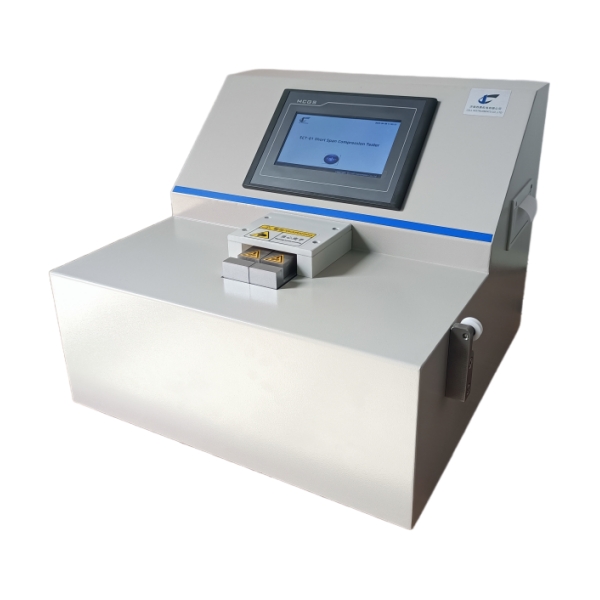

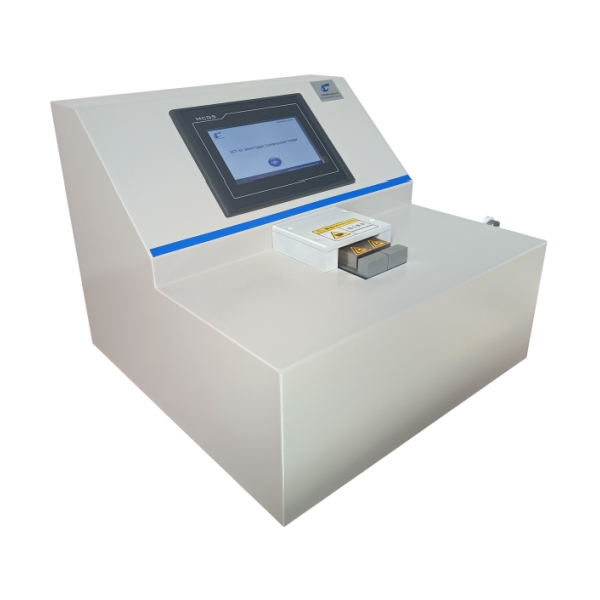

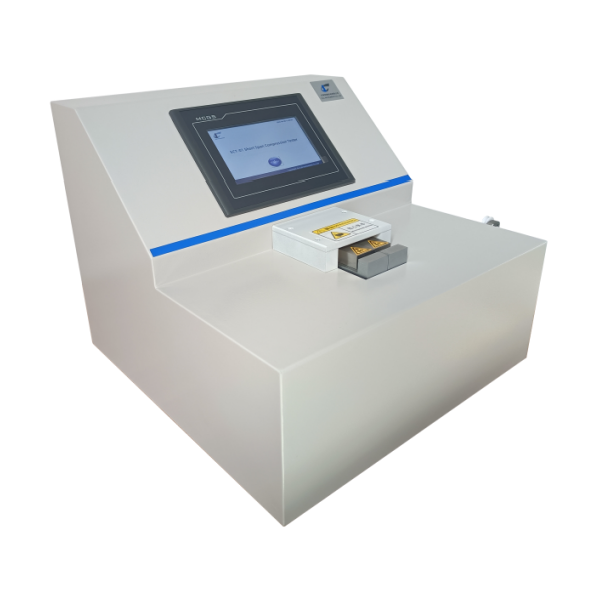

Cell Instruments' SCT-01 Tester tlaku s krátkým rozpětím offers high performance, ease of operation, and compliance with international standards, especially ISO 9895, which governs the Test SCT method.

SCT Test and ISO 9895

The Test SCT (Short-Span Compression Test) as defined in ISO 9895, measures the compressive strength of paper and board over a very short span—typically 0.70 mm. This test is vital for materials used in the production of corrugated boxes, cartons, and paperboard containers, where high compressive performance is required.

Unlike traditional compression tests, the SCT test focuses on edgewise compressive strength, simulating conditions during stacking and palletization. It is particularly suitable for papers and boards ranging in grammage from 100 g/m² to 400 g/m².

Key Features of SCT-01 Short Span Compression Tester

The SCT-01 Tester tlaku s krátkým rozpětím from Cell Instruments is engineered for accuracy and durability. Its advanced features meet the rigorous needs of laboratory and industrial environments:

-

PLC-controlled system s HMI touch-screen operation for user-friendly interaction

-

Pneumatic sample clamping with adjustable clamping force to ensure test consistency

-

Constant test speed with programmable settings for various material types

-

Emergency stop button a over-range protection for enhanced safety

-

Multi-unit force display: N (Newtons), kgf (Kilogram-force), and lbf (Pound-force)

-

Built-in dot matrix printer for instant results printing

-

RS 232 COM port and optional PC software for data management and traceability

How the SCT Test Works

1. Sample Preparation

-

Cutting the Test Piece

Prepare rectangular test specimens from the paper or board sample. Each specimen should measure 15 mm in width a 75 mm in length. -

Conditioning the Samples

Condition the specimens in a controlled environment of 23 ± 1°C temperature a 50 ± 2% relative humidity for at least 4 hours before testing, as required by ISO 187 (referenced by ISO 9895). This stabilizes the paper’s physical properties. -

Selecting the Test Direction

Determine whether the test will be conducted in the směr stroje (MD) nebo cross direction (CD). Prepare a minimum of pět exemplářů for each direction to ensure statistical validity.

2. Mounting the Sample

-

Open Clamps

Using the pneumatic control system, open the clamps. -

Insert the Test Piece

Center the specimen between the 30 mm-long clamps, ensuring it is aligned with the jaws and is positioned evenly along the width. -

Apply Clamping Pressure

Activate the pneumatic clamping mechanism to grip the specimen. The high-friction surfaces help prevent slippage during compression.

3. Executing the Test

-

Spusťte test

Press the start button on the HMI panel to begin the compression. -

Compression Process

The movable clamps move toward each other at the set speed of 3 mm/min. As the span closes, the paper or board is subjected to increasing edgewise compressive force. -

Failure Detection

The test continues until the specimen fails structurally—typically by buckling or sudden breakage. The instrument automatically records the maximum force applied before failure.

4. Test Completion and Result Recording

-

Display of Results

The compressive strength is displayed in selectable units:-

N (Newtons)

-

kgf (Kilogram-force)

-

lbf (Pound-force)

-

-

Print or Export Data

Results can be printed directly via the embedded dot matrix printer or exported through the RS-232 COM port using optional PC software.

Why Choose Cell Instruments’ SCT-01

With a reputation for innovation and customization, Buněčné nástroje delivers not just standard testing solutions, but also tailored instruments for specific material testing needs. The SCT-01 represents our commitment to precision, compliance, and usability in the field of short span compression testing.

Our technical team supports clients with modernizace automatizace, test method consultinga training, ensuring your lab operates efficiently and accurately.

The kompresní tester s krátkým rozpětím is critical for determining the strength and stability of paperboard materials. Its alignment with ISO 9895 makes it the preferred method for accurate SCT testing. Whether you’re producing corrugated containers or verifying paper stock, the SCT-01 from Cell Instruments provides the performance and reliability required to maintain your quality standards.