GFT Gelbo Flex Tester

- Standard: ASTM F392

- Fabrikant: Celleinstrumenter

- Ansøgninger: Emballagematerialer, materialer til medicinsk udstyr, farmaceutiske tests, klæbemidler, tekstiler, papir- og papbeholdere og mere.

- Tilpasning: Tilgængelig til specielle testkrav og automatiseringstransformationer

Introduction of Gelbo Flex Tester

De Gelbo Flex Tester is a specialized instrument designed to evaluate the flex durability and mechanical integrity of flexible materials such as barrier films, laminates, and coated fabrics. By simulating real-world twisting and compressive deformation, this tester provides critical insights into the resistance of packaging and coated materials to pinhole formation, cracking, og barrier property degradation. Standards such as ASTM F392 og ISO 7854 define the testing methods that ensure accuracy, repeatability, and international comparability.

De Gelbo Flex Tester, sometimes referred to as a rumple flex tester eller flex tester, operates by subjecting test specimens to simultaneous twisting and compressing motions. This combined action reproduces the mechanical stress flexible packaging materials experience during filling, sealing, transportation, and storage.

The test method, commonly known as the Gelbo test method, evaluates a material’s ability to maintain integrity under cyclic deformation. Materials that fail this test often develop microscopic pinholes or cracks that compromise the package’s barrier performance against oxygen, moisture, or gas transmission.

Principle of the Gelbo Flex and Related Standards

Two primary international standards govern flex durability evaluation: ASTM F392 og ISO 7854.

ASTM F392, titled Standardpraksis for konditionering af fleksible barrierematerialer for fleksibel holdbarhed, specifies test conditions for assessing the resistance of flexible packaging materials to flex-induced pinholes and barrier failures. In this method, specimens undergo repeated flexing at 45 cycles per minute, involving a 440° twist combined with a 65 mm horizontal motion. The test is conducted under standard conditions of 23 ± 2°C og 50 ± 5% relative humidity. Depending on the desired conditioning level, test cycles may range from 20 to 2700, corresponding to levels A through E.

ISO 7854, Rubber- or plastics-coated fabrics — Determination of resistance to damage by flexing, defines three methods of flex testing. Method C, known as the crumple/flex method, closely resembles the Gelbo principle. Here, a cylindrical specimen is subjected to oscillating twist and axial compression, simulating real-life flex stress for coated fabrics, medical materials, and technical textiles.

Together, these standards establish the Gelbo flex procedure as the global benchmark for flex durability testing.

How the Gelbo Flex Tester Works

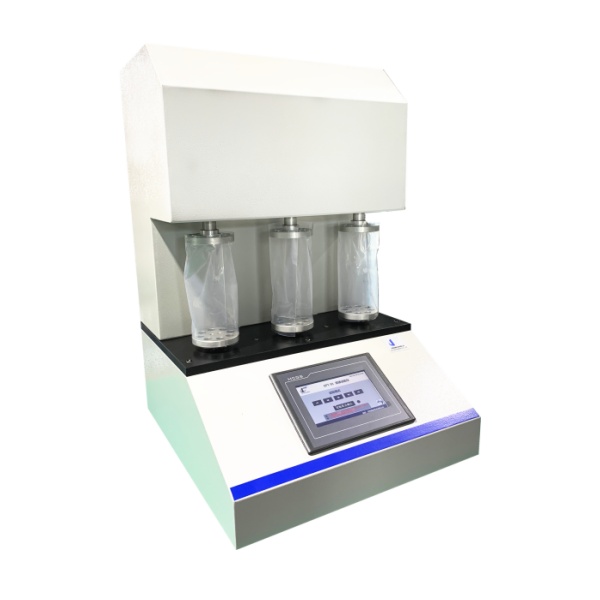

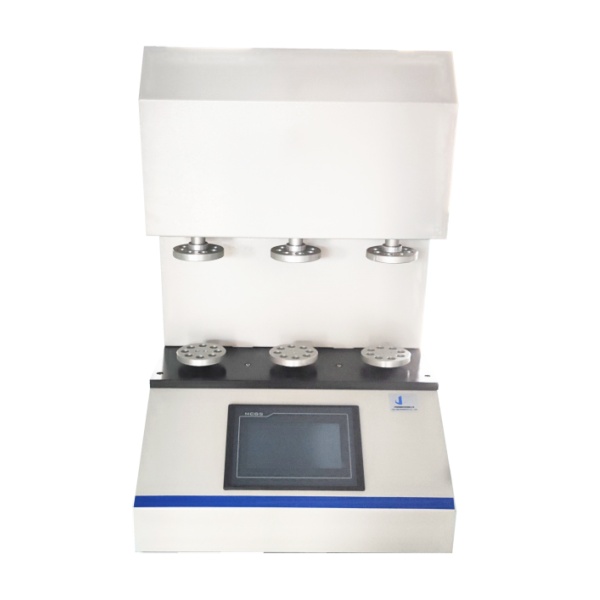

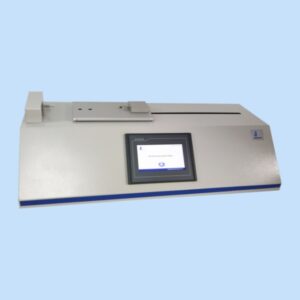

De Gelbo Flex Tester (for example, the GFT Flex Durability Tester by Celleinstrumenter) operates with high precision to replicate ASTM and ISO flexing motions.

- Prøveforberedelse: Standard samples are 200 × 280 mm, cut in both machine and transverse directions.

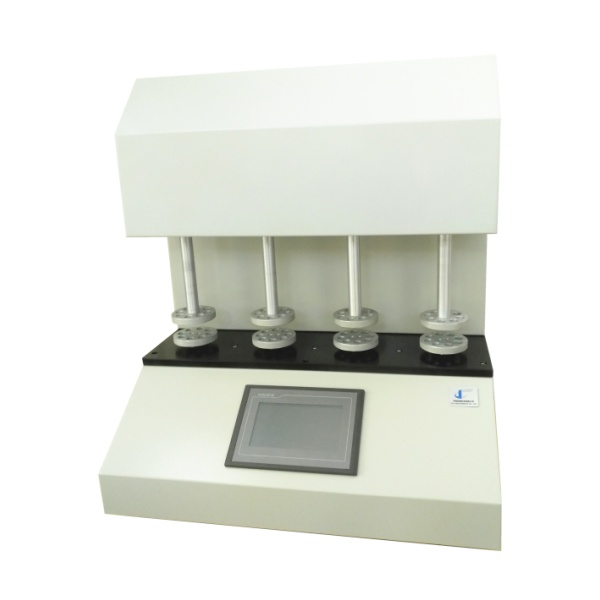

- Mounting: Samples are clamped or adhered to the tester’s mandrels, forming a cylindrical shape for simultaneous twisting and compression.

- Flexing Cycle: The tester executes a 440° twist during the first 90 mm of stroke, followed by a 65 mm linear compression, at a consistent 45 cycles per minute.

- Mode Selection: Users can select from five programmable test modes (A–E) to suit different material types or test objectives.

- Result Evaluation: After conditioning, specimens are inspected for pinholes, cracks, or barrier degradation using OTR (Oxygen Transmission Rate), WVTR (Water Vapor Transmission Rate), or GTR tests.

This controlled process allows laboratories and quality control teams to quantify a material’s flex resistance and predict its performance under real-world mechanical stress.

Key Features and Main Parameter

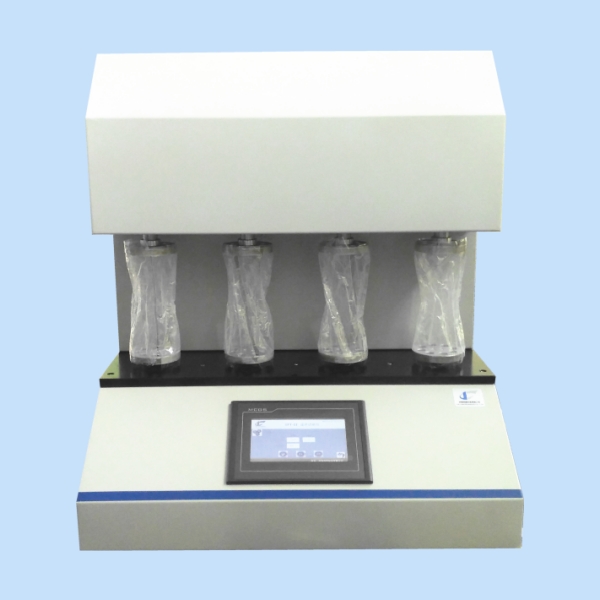

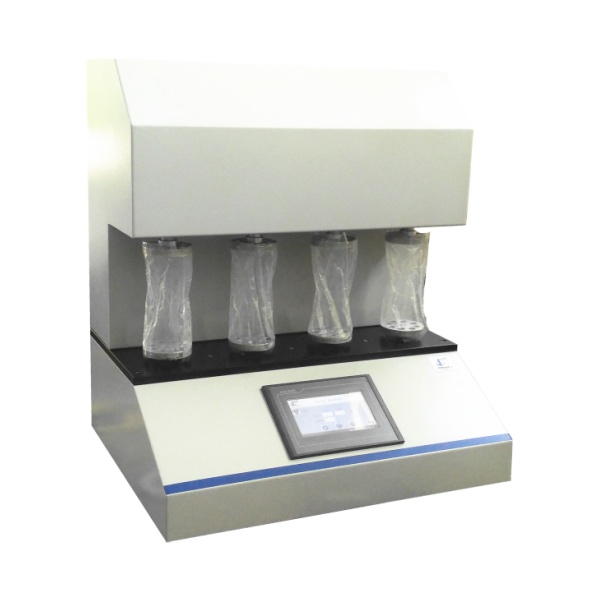

De GFT Gelbo Flex Tester series from Celleinstrumenter offers advanced technology designed for high precision and ease of use:

- PLC Control & Touchscreen Interface – Ensures accurate motion control, user-friendly operation, and data repeatability.

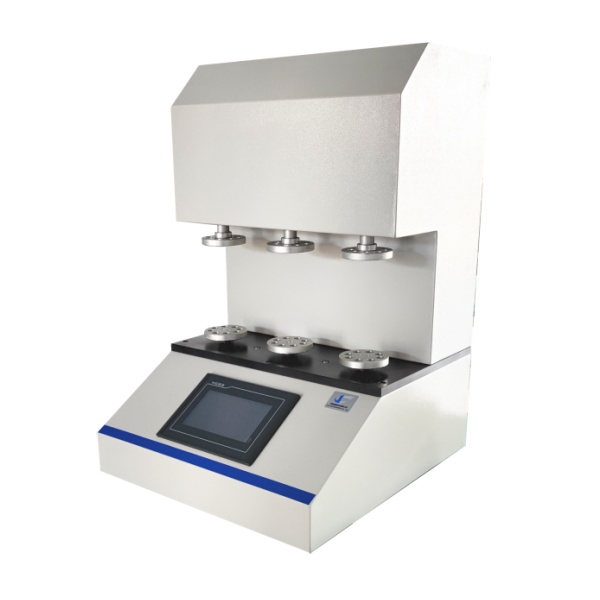

- Multiple Test Stations – Available with three or four stations for parallel testing and comparative analysis.

- Programmable Test Conditions – Supports ASTM F392 modes A–E for versatile testing from quick screening (20 cycles) to endurance evaluation (2700 cycles).

- Durable Mechanical Design – Engineered for long-term stability and compliance with ASTM F392 og ISO 7854 standarder.

- Enhanced Data Reliability – Supports post-test evaluation of barrier integrity, pinhole formation, and mechanical strength changes.

| GFT Gelbo Flex Durability Tester | ||

| Parameter | GFT-02 Model | GFT-01 Model |

| Flex vinkel | 440° (90 mm) eller 400° (80 mm) | |

| Kapacitet | 3.5 N.m | 2,5 Nm |

| Vandret streg | 155 mm eller 80 mm | |

| Stationer | 3 | 4 |

| Prøvestørrelse | 280 mm x 200 mm | |

| Magt | 110~220V | |

Applications of Gelbo Flex Testing

Gelbo flex testing is essential in industries where flexible materials must retain barrier integrity and aesthetic quality after repeated handling or mechanical stress. Key application areas include:

- Flexible Packaging for food, pharmaceuticals, and medical devices

- Coated Fabrics and Films for industrial, textile, and outdoor uses

- Adhesive Laminates og composite structures

- Kvalitetskontrol in R&D laboratories og certification agencies

By identifying weak points early, manufacturers can improve material formulation, coating technology, and lamination processes.

Ofte stillede spørgsmål

Sv: Cell Instruments' Gelbo Flex Tester kan prale af en unik blanding af præcisionsteknik og innovative designfunktioner. Fra dens intuitive brugergrænseflade til dens avancerede automatiseringsfunktioner er hvert aspekt omhyggeligt udformet for at optimere ydeevne og brugeroplevelse. Derudover adskiller dens kompatibilitet på tværs af en lang række materialer og industrier den som en alsidig løsning til behov for flextest.

A: Ved at udsætte materialer for streng flextestning hjælper flex holdbarhedstesteren med at identificere svagheder og potentielle fejlpunkter tidligt i udviklingsprocessen. Denne proaktive tilgang gør det muligt for producenter at løse problemer, før de eskalerer, hvilket resulterer i produkter, der er mere modstandsdygtige, pålidelige og i sidste ende af højere kvalitet.

A: Absolut! Gelbo Flex Testeren er designet til at rumme en bred vifte af prøvestørrelser og -former, hvilket giver fleksibilitet og alsidighed i test. Uanset om du arbejder med små, sarte film eller større, mere omfangsrige materialer, kan vores tester nemt tilpasse sig dine specifikke testkrav.

A: Præcision er altafgørende med flex holdbarhedstesteren. Gennem omhyggelig kalibrering og robust konstruktion sikrer vi, at hver test giver ensartede, pålidelige resultater. Derudover er vores tester designet til at minimere eksterne faktorer, der kan påvirke testresultater, hvilket yderligere forbedrer nøjagtigheden og repeterbarheden.

A: Hos Cell Instruments prioriterer vi kundetilfredshed og support. Vores dedikerede tekniske supportteam er til rådighed for at hjælpe brugere med spørgsmål, bekymringer eller tekniske udfordringer, de måtte støde på. Uanset om du har brug for hjælp til opsætning, kalibrering eller fejlfinding, er vores eksperter her for at give hurtig og effektiv support for at sikre, at dine testprocesser kører problemfrit

Reference

ASTM F392 Standardpraksis for konditionering af fleksible barrierematerialer for fleksibel holdbarhed