ASTM D4917

Coefficient Of Friction Tester method

Der ASTM D4917 standard outlines a precise horizontal plane method for determining the coefficient of static and kinetic friction (COF) of uncoated writing and printing paper. In paper converting, printing, and packaging industries, friction characteristics play a critical role in machine feed reliability, print accuracy, and material handling efficiency. This test method is especially relevant for coefficient of friction test of paper, particularly when assessing the surface behavior of uncoated and printing papers.

Understanding the frictional behavior of paper not only ensures smooth operation of high-speed printers and copiers but also supports material quality control and design optimization. For professional quality control teams, ASTM D4917 provides a reproducible and standard-driven approach to evaluating paper surface interactions.

Understanding Coefficient of Friction in Paper Testing

Coefficient of friction (COF) is a crucial parameter that reflects the resistance to motion between two surfaces. In paper applications, this value influences how one sheet slides over another. The static COF determines the force required to start the movement, while the kinetic COF measures the force needed to maintain the movement at a constant speed. ASTM D4917 enables both measurements using horizontal sliding motion.

Test Equipment and Sample Preparation Considerations

To conduct reliable COF tests according to ASTM D4917, specialized equipment is essential. A constant-rate-of-motion tester, equipped with a load cell and capable of pulling a sled at 150 ± 30 mm/min, is typically used.

For accurate results, samples should be preconditioned under standard atmospheric conditions (as per TAPPI T402 or ASTM D685) and prepared in alignment with machine direction and grain orientation.

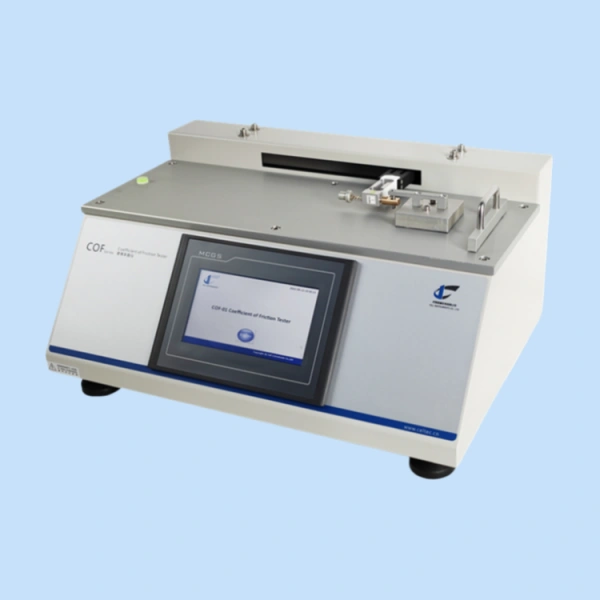

We recommend the Cell Instruments COF-01 Coefficient of Friction Tester, a high-precision horizontal plane instrument designed to meet the requirements of ASTM D4917 and ISO 8295. It features digital control, adjustable sled options, and automated force measurement—ensuring accurate, reproducible results for both static and kinetic COF tests.

Paper Static and Kinetic Friction Testing Explained

Paper testing under ASTM D4917 involves placing one sheet of paper on a flat horizontal surface and placing another identical sheet on top. A sled (usually rubber-faced) is placed over the top sheet. As the sled is pulled, the force required to initiate motion (static friction) and the force required to continue motion (kinetic friction) are measured.

Das paper kinetic friction testing Und paper static friction testing provides critical data for understanding sheet separation, feed consistency, and print alignment in high-speed systems.

Applications of ASTM D4917 in Printing and Uncoated Paper COF Testing

Der printing paper COF test is particularly important in pressroom environments, where frictional consistency ensures single-sheet feed accuracy and reduces jams or misfeeds. Similarly, uncoated paper COF test helps paper manufacturers verify product specifications before converting or delivery.

In both applications, ASTM D4917 offers a standardized approach that reduces testing variability and ensures compliance with industry quality benchmarks.

Why Use ASTM D4917 Instead of Other Methods?

Unlike inclined plane methods (such as ASTM D4918), which cannot determine kinetic COF, ASTM D4917 allows accurate evaluation of both static and kinetic friction through horizontal movement. Furthermore, it minimizes sliding wear by testing only on the first contact, which better simulates real-world sheet handling scenarios.

For more rigid materials like corrugated board, ASTM D4521 or ASTM D3247 is more appropriate. But for thin, flexible, uncoated papers, D4917 is the go-to method recommended by most paper converters and packaging laboratories.

Choosing the Right Coefficient Of Friction Tester

To comply with ASTM D4917 and achieve accurate paper COF results, we recommend the Zellinstrumente COF-01 Tester, which is optimized for:

- horizontal testing

- Static and kinetic friction measurements

- Custom fixture design for uncoated and specialty papers

- Smart data recording

Backed by robust engineering and application support, Cell Instruments’ friction testers ensure precision and repeatability across various paper substrates.

Contact Us Get ASTM D4917 Testing Solution

Friction characteristics of paper materials significantly influence performance in printing, packaging, and converting operations. ASTM D4917 provides a standardized, reliable framework to measure both static and kinetic friction of uncoated writing and printing paper. With precise instrumentation like the COF-01 by Zellinstrumente, quality professionals can confidently execute tests, interpret results, and implement improvements.

Whether you’re testing for paper kinetic friction, static friction, printing paper COF, or conducting an uncoated paper COF test, understanding and applying ASTM D4917 ensures your results are meaningful, reproducible, and aligned with global standards.

FAQs

ASTM D4917 measures the coefficient of static and kinetic friction of uncoated writing and printing paper using a horizontal plane method.

Friction affects feed reliability in printers and copiers, and ensures proper handling in converting and packaging machinery.

Static COF measures the force to start motion between two surfaces, while kinetic COF measures the force to continue that motion.

While it is optimized for uncoated writing and printing papers, ASTM D4917 may be used with other paper types, though results may vary in precision.