Understanding Rub Resistance and Its Importance

Rub resistance refers to the ability of printed materials to withstand abrasion during handling, shipping, and usage. Poor rub resistance can lead to fading, smudging, or loss of critical printed information, directly impacting product quality and brand integrity. In industries like food, pharmaceuticals, and consumer electronics, preserving print quality is essential. Rub resistance becomes especially critical for high-end packaging, including labels with holographic printed layers, where even minor surface damage can compromise visual appeal or legibility.

To help quality professionals and manufacturers ensure product performance, standards such as ASTM D5264 και TAPPI T830 provide structured methods for evaluating rub resistance under controlled conditions.

Ο Sutherland ink rub tester is a standardized device specifically designed to measure the abrasion resistance of printed surfaces. It operates by repeatedly rubbing a weighted test specimen against a printed sample to simulate real-world scuffing or handling damage.

According to ASTM D5264, the procedure involves:

- Mounting a printed specimen on a rubber pad attached to the Sutherland base.

- Attaching a receptor (such as plain paper or a similar printed surface) to a 2-lb or 4-lb weight.

- Running the tester for a preset number of strokes, where one stroke equals one back-and-forth motion.

- Visually inspecting the sample for υποβάθμιση εκτύπωσης and the receptor for μεταφορά μελανιού.

This method evaluates ink performance, coating durability, and substrate resistance in a επαναλαμβανόμενο και quantifiable manner.

Applications for Holographic Printed Layers

Holographic printed layers—commonly used in premium packaging, security labels, or decorative films—present unique challenges for rub resistance due to their multi-layered and often delicate construction. They are prone to abrasion, especially during transportation or shelf handling.

Rub testing, as per TAPPI T830, is especially useful for these materials. This standard enables the assessment of rub resistance by comparing the printed material against a reference standard under the same conditions. For holographic labels, both dry rub και υγρό τρίψιμο evaluations are essential to simulate real-world stress conditions.

Performing a Successful Rub Resistance Test: Best Practices

To obtain reliable results from rub resistance testing, consider the following technical tips:

- Προετοιμασία δείγματος: Samples should be flat, clean, and free from ridges or fingerprints. Ensure consistent ink coverage and density across all test samples.

- Environment Conditioning: Condition specimens at 23 ± 1°C and 50 ± 2% RH to eliminate environmental variables.

- Selection of Test Parameters: Choose the appropriate weight (2-lb or 4-lb) and number of strokes based on expected usage scenarios. Excessive strokes can generate heat and affect results.

- Receptor Type: Depending on the end-use, receptors may be unprinted substrates or duplicate printed sheets. Choose based on the intended abrasion evaluation.

- Visual and Instrumental Evaluation: Results may be visually rated (pass/fail) or quantified using a densitometer ή spectrophotometer to measure color shift or density loss.

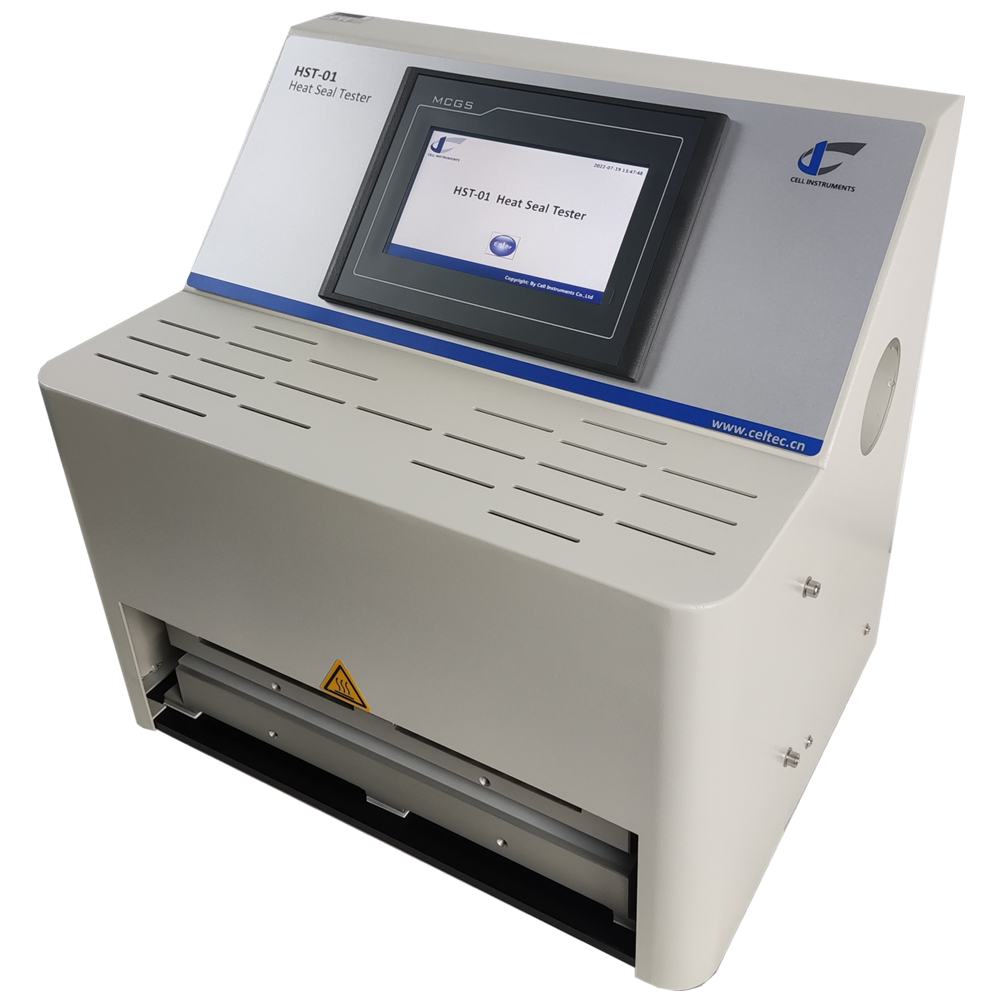

Recommended Equipment: Cell Instruments RT-01 Ink Rub Tester

For manufacturers seeking precise, repeatable rub resistance evaluation, the RT-01 Ink Rub Tester από Κυτταρικά όργανα is a proven solution. It meets both ASTM D5264 και TAPPI T830 standards, offering customizable testing parameters for diverse substrates—including holographic printed layers and specialty inks.

Features include:

- Multiple test weights and stroke settings.

- High stability and precision mechanics.

- Compatibility with both dry and wet rub methods.

- Ideal for R&D, quality control labs, and production floor checks.

With the RT-01, manufacturers can confidently evaluate print durability across packaging, labeling, and decorative printing sectors.

Use Cases and Industry Relevance

Rub resistance testing is widely applicable across industries:

- Pharmaceutical packaging: Ensures dosage information remains legible.

- Συσκευασία τροφίμων: Verifies print integrity under refrigerated or wet conditions.

- Luxury goods: Maintains high-end visual standards of holographic films or foil stamping.

- Ηλεκτρονική: Prevents scuffing on branding labels and user information.

Testing not only ensures compliance with customer expectations but also reduces risk of rejections, complaints, and potential recalls.

Σύναψη

Rub resistance is a key performance metric for printed materials, particularly in sensitive or visually demanding applications. By using standardized methods such as ASTM D5264 και TAPPI T830, and reliable instruments like the Sutherland ink rub tester ή Κυτταρικά όργανα RT-01, quality control professionals can evaluate and improve product durability effectively.

Understanding how to conduct rub resistance testing helps safeguard brand reputation, maintain compliance, and ensure consumer satisfaction.