Guía completa de comprobadores de nivel de CO2 para el análisis de la carbonatación de bebidas

Introducción al comprobador de nivel de CO2

A comprobador de nivel de co2 desempeña un papel fundamental en la evaluación de los niveles de carbonatación en bebidas carbonatadas como refrescos, agua con gas, cerveza y bebidas funcionales. La medición precisa del CO₂ ayuda a garantizar la consistencia del sabor, la integridad del envase y la vida útil del producto. Dado que las marcas de bebidas compiten en calidad y fiabilidad, los laboratorios y las plantas de llenado confían cada vez más en los análisis precisos de CO₂ para mantener los estándares de los productos y verificar el rendimiento de los envases.

Cell Instruments se especializa en soluciones de pruebas de materiales y envases, y nuestros sistemas de pruebas de carbonatación ayudan a los productores de bebidas, proveedores de envases y organismos de inspección de calidad a obtener datos fiables sobre la carbonatación tanto para entornos de desarrollo como de producción.

Importancia de las pruebas según ASTM F1115

ASTM F1115 Requisitos de ensayo para la medición de la carbonatación

Norma ASTM F1115 define un método estructurado para determinar la pérdida de dióxido de carbono en los envases de bebidas mediante la medición de los niveles de carbonatación inicial y final a intervalos especificados. La norma describe dos procedimientos prácticos -A y B- que ayudan a los usuarios a evaluar la vida útil, verificar los parámetros de llenado y comparar diseños de envases.

El procedimiento A se centra en pruebas de laboratorio de alta precisión que utilizan sensores de micropresión y temperatura. El procedimiento B utiliza dispositivos de presión-temperatura más sencillos o analizadores de CO₂ automatizados, lo que lo hace adecuado para el control de calidad rutinario. Al seguir la norma ASTM F1115, los fabricantes de bebidas obtienen un método estructurado y repetible para controlar la retención de carbonatación y detectar problemas como fugas de CO₂, sellado incorrecto o deformación de la botella.

Cómo ayuda un medidor de nivel de CO2 al control de calidad de las bebidas

A comprobador de nivel de co2 proporciona información directa sobre el comportamiento de la carbonatación durante el almacenamiento y la distribución del producto. Permite a los usuarios:

- Medir los niveles de carbonatación inicial y final

- Verificar la presión de llenado de CO₂ durante el embotellado.

- Detectar precozmente las pérdidas de CO₂ causadas por defectos de cierre.

- Evaluar los diseños de botellas durante el desarrollo

- Estimar la caducidad en función de las curvas de retención

Comprender cómo afectan la temperatura y las condiciones de almacenamiento a la carbonatación

Dado que los cambios en el contenido de CO₂ influyen en el sabor, la sensación en boca y las características de la espuma, un control constante garantiza que la bebida mantenga la calidad prevista desde el llenado hasta el consumo.

Conceptos clave de los ensayos basados en ASTM F1115

Control de la carbonatación inicial y final

La norma ASTM F1115 exige llenar los recipientes con agua carbonatada o producto hasta alcanzar al menos 4,5 volúmenes de CO₂. Tras el sellado, los usuarios miden la presión y la temperatura de equilibrio iniciales para determinar el nivel de carbonatación inicial.

Evaluación de la pérdida de carbonatación a lo largo del tiempo

Las mediciones programadas -como después de 24 horas, 3 días, 1 semana e intervalos adicionales- permiten a los usuarios calcular el porcentaje de retención de carbonatación. Estas lecturas ayudan a detectar patrones de pérdida de CO₂ y a identificar estructuras de envasado débiles.

Estabilidad de temperatura y presión

Las lecturas estables de presión y temperatura son esenciales. El equilibrio de la botella en condiciones ambientales controladas evita falsas lecturas de pérdida de CO₂ causadas por la fluctuación de la temperatura o el retraso en el equilibrio.

Identificación de interferencias

La norma ASTM F1115 destaca problemas potenciales como:

- Fuga de cierre

- Configuración incorrecta del equipo de presión

- Exceso de aire en la cabeza

- Variación del grosor de la pared de la botella

- Efectos de la humedad ambiental

Controlando estos factores, los usuarios pueden evitar resultados inexactos y mantener una alta fiabilidad de las pruebas.

Cómo realizar pruebas de carbonatación con un comprobador de nivel de CO2

1. Preparar y acondicionar las muestras

Acondicionar las botellas en 23 °C ± 2 °C y 50% ± 5% RH durante 72 horas. Un acondicionamiento adecuado garantiza un equilibrio presión-temperatura constante.

2. Llenado y sellado de contenedores

Rellenar con líquido carbonatado enfriado a 5 °C o inferior, y luego aplicar los cierres. Asegúrese de que el cierre es hermético para evitar fugas de CO₂.

3. Medir la carbonatación inicial

Con un comprobador de nivel de co2, agita la botella y registra la presión y la temperatura de equilibrio. Convierte estos valores en volúmenes de CO₂ utilizando una tabla de carbonatación.

4. Almacenar y probar a intervalos programados

Medir la carbonatación en períodos determinados. Para el procedimiento A, se pueden tomar lecturas frecuentes de laboratorio utilizando transductores de presión sensibles; el procedimiento B utiliza dispositivos manuales o automatizados de presión-temperatura.

5. Analizar la retención de carbonatación

Represente gráficamente la retención de carbonatación frente al tiempo. La vida útil se determina cuando los niveles de CO₂ caen por debajo del umbral aceptable. Estos datos también ayudan a comparar materiales de envasado, diseños de botellas y sistemas de cierre.

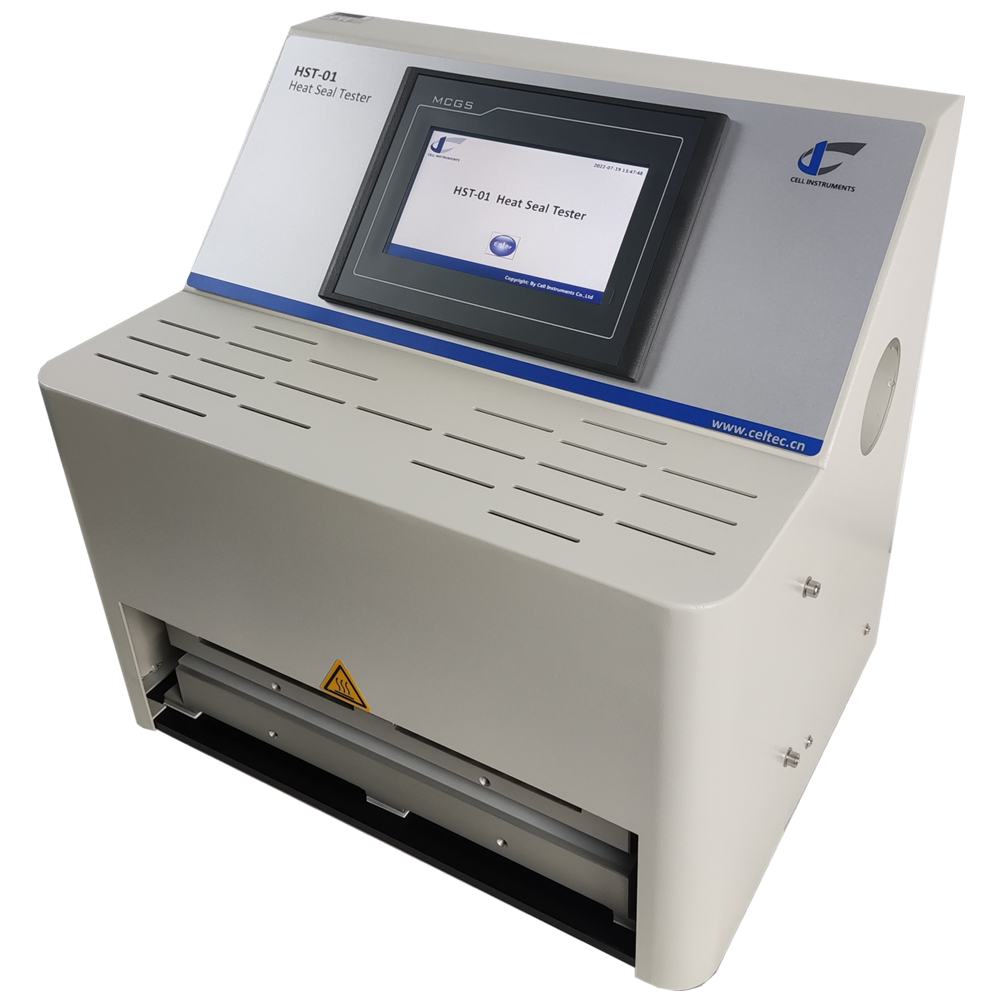

Por qué elegir las soluciones de comprobación de niveles de CO2 de Cell Instruments

Cell Instruments proporciona equipos avanzados diseñados para la medición precisa de la carbonatación en todos los formatos de envasado de bebidas. Nuestro comprobador de nivel de co2 oferta de sistemas:

- Medición de presión y temperatura de alta precisión

- Cálculos de carbonatación estables y repetibles

- Compatibilidad con los procedimientos A y B de ASTM F1115

- Construcción duradera para laboratorio y líneas de producción

- Automatización opcional para reducir la variabilidad del operario

Estos instrumentos ayudan a los departamentos de I+D, a los equipos de control de calidad y a las plantas de producción a conseguir pruebas de CO₂ fiables y estandarizadas, lo que contribuye a mejorar la consistencia de los productos y a reducir los defectos de calidad.

Conclusión

A comprobador de nivel de co2 es esencial para los fabricantes de bebidas que desean mantener la estabilidad de la carbonatación, optimizar el diseño del envase y garantizar la calidad del producto. Siguiendo los métodos estructurados especificados en Norma ASTM F1115Con los instrumentos de prueba de Cell Instruments, los usuarios pueden evaluar la retención de CO₂ con precisión, identificar los factores que provocan la pérdida de carbonatación y optimizar el rendimiento de la botella y el cierre. Con los fiables instrumentos de ensayo de Cell Instruments, los fabricantes de bebidas adquieren la confianza necesaria para garantizar la calidad y el cumplimiento de la normativa durante todo el ciclo de producción.