rõhu lagunemise katse

KatsemeetodPakendite terviklikkuse tagamine on kriitilise tähtsusega meditsiini-, farmaatsia- ja toiduainetööstuses. Veebileht ASTM F1140 standard pakub põhjalikke meetodeid, et hinnata siserõhu all olevate piiranguteta pakendite tõrkekindlust. Need hõlmavad lõhkekatse, libisemiskatseja rõhu lagunemise katse, mis simuleerivad steriliseerimise, transpordi ja ladustamise ajal esinevaid tingimusi. Selles artiklis selgitatakse rõhu lagunemise katse põhiolemust ja seda, kuidas Cell Instruments pakub täiustatud lahendusi nende testimisnõuete täitmiseks.

Mis on ASTM F1140 ja rõhu lagunemise katse?

ASTM F1140 on ASTM Internationali poolt välja töötatud standardiseeritud meetod, mille abil hinnatakse sisemise rõhu all olemise rikke vastupidavus paindlikud, piiramata pakendid. Selles on määratletud kolm peamist katsemeetodit:

- Lõhkekatse (katsemeetod A)

- Tõmbekatse (katsemeetod B1)

- Tõmbetugevuse katse (katsemeetod B2)

Need meetodid aitavad tootjatel tuvastada nõrgad tihendid, materjali ebakõlad ja konstruktsioonivead, mis võivad ohustada pakendi terviklikkust rõhu all.

ASTM F1140 nõuetele vastavuse lõhkekatse mõistmine

The lõhkekatse on üks levinumaid meetodeid ASTM F1140 alusel. See hõlmab suletud pakendi sisemise õhurõhu järkjärgulist suurendamist, kuni see puruneb.

Eesmärk ja eelised:

- Identifitseerib maksimaalne surve pakend võib vastu pidada.

- Hindab tugevust ja pitserite järjepidevus.

- Simuleerib äärmuslikke tingimusi, nagu steriliseerimine või kõrgusega seotud rõhumuutused.

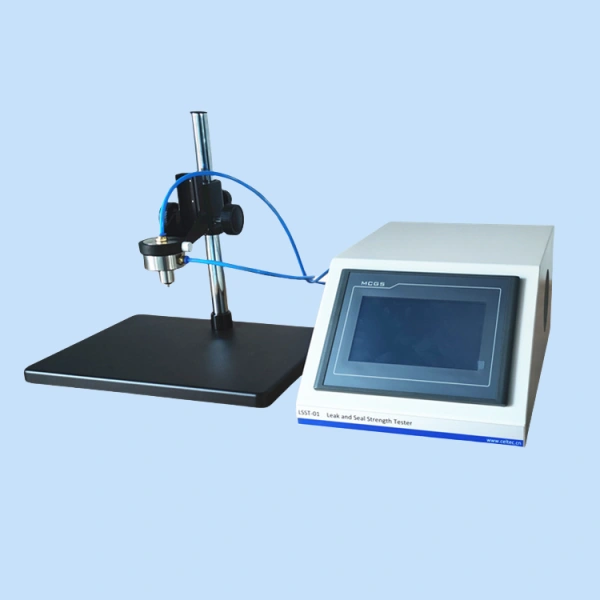

Rakuinstrumendid Purske tester on mõeldud spetsiaalselt ASTM F1140 lõhkekatsete jaoks. See võimaldab kasutajatel täpselt kontrollida survestamise kiirust ja tuvastada täpne rõhk, mille juures pakend puruneb. See tagab korratavad, nõuetele vastavad ja täpsed tulemused.

Creep Test: Kestva rõhu hindamine

The libisemiskatse (katsemeetod B1) hindab, kui hästi säilitab pakend kindlaksmääratud aja jooksul (tavaliselt 15-30 sekundit) kindlaksmääratud rõhku.

Rakendused:

- Protsessi valideerimine pakendi arendamise ajal.

- Avastab aeglased lekked või nõrgad kohad, mis ei ole lõhkekatse käigus nähtavad.

- Kasutatakse sageli meditsiiniseadmete pakendid, kus steriilsust tuleb säilitada stressi tingimustes.

Cell Instruments’ katsesüsteemid suudavad säilitada pidevat siserõhku suure täpsusega. Soovitatav lähtepunkt on 80% teadaoleva lõhkemisrõhu kohta, mis tagab sisulise väljakutse ilma kohese ebaõnnestumiseta.

https://youtu.be/aDSEwpQqoE0?si=GB2HNvRg5Ken5TeIKahanemine kuni ebaõnnestumiseni: Pushing the Limits

Agressiivsem vorm roomamiskatse, mis on ebaõnnestumiseni hiilimine meetod (katsemeetod B2) suurendab rõhku ligikaudu 90% plahvatusliku väärtusega ja hoiab seda, kuni pakett ebaõnnestub.

Miks seda kasutada?

- Hinnatakse pikaajalist rõhu säilitamist ja tihendi lagunemist.

- Määratleb aeg kuni ebaõnnestumiseni, mis annab täiendavaid andmeid kvaliteedi tagamiseks.

See meetod sobib ideaalselt võrdlusuuringute tegemiseks tulemuslikkus pikaajalise stressi korral ja tuvastatakse pakendivigu, mis ilmnevad alles pärast püsivat sisemist survet.

Rõhu lagunemise katse: Mittepurustav alternatiiv

The rõhu lagunemise katse, kuigi seda ei ole ASTM F1140-s sõnaselgelt kirjeldatud, kasutatakse seda sageli koos lõhkekatse ja roomavuskatsega. See meetod hõlmab pakendi täispuhumist kindlaksmääratud rõhuni ja selle jälgimist. lagunemiskiirus aja jooksul.

Eelised:

- Mitte-destruktiivne: Võimaldab pakendite taaskasutamist, kui lekkeid ei tuvastata.

- Väga tundlik mikrolekked.

- Kasulikud kvaliteedikontrolli keskkonnad mis nõuavad kiireid ja usaldusväärseid tulemusi.

Cell Instruments pakub täiustatud süsteeme, mis integreerivad rõhu langemise meetod testimine, pakkudes pakendi terviklikku lahendust pakendi terviklikkuse kontrollimiseks.

Põhiparameetrid usaldusväärsete tulemuste saavutamiseks

ASTM F1140 katsete tegemisel on järjepidevus kriitiline. Katsete täpsust mõjutavad järgmised tegurid:

- Pakendi suurus ja kuju

- Plommi konfiguratsioon

- Materjali omadused

- Survestamise kiirus

- Suletud pakendite sisenemispunkti asukoht

- Seadmete tundlikkus

Kõiki neid tuleb kontrollida, et tagada korratavad tulemused partiide ja katselaborite lõikes. Cell Instruments lõhkekatseseadmed ja rõhuandurid tagavad iga parameetri kõrge eraldusvõimega kontrolli.

Õige instrumendi valimine: COF-03 hõõrdeteguri tester

Rakuinstrumendid pakub terviklikku lahendust ASTM F1140 katsetamiseks, sealhulgas lõhkemis-, roomamis- ja rõhu langemisvõimalusi. Meie seadmed pakuvad:

- Täpne rõhu reguleerimine ja mõõtmine

- Kasutajasõbralikud kasutajaliidesed koos programmeeritavate seadistustega

- Automatiseeritud andmete kogumine ja aruandlus

- ASTM standarditele vastavad konstruktsioonid

Meie lõhkekatseid kasutatakse laialdaselt meditsiiniseadmete tootmine, toiduainete pakendamine ja ravimite kvaliteedikontroll protsessid.

Olenemata sellest, kas valideerite uusi pakkematerjale, kvalifitseerite tootmispartiisid või uurite rikkumisi, Cell Instruments süsteemid tagavad järjepidevad ja usaldusväärsed katsetulemused.

Võtke meiega ühendust Hankige rõhu lagunemise testimise lahendus

ASTM F1140 mängib kriitilist rolli siserõhu all olevate paindlike pakendite terviklikkuse kontrollimisel. Kasutades asjakohaseid meetodeid, nagu näiteks lõhkekatse, libisemiskatseja rõhu langemise meetod, saavad tootjad kindlalt hinnata tihendi tugevust, pakendi konstruktsiooni ja üldist töökindlust.

Ettevõtetele, kes soovivad täpsust ja vastavust, Cell Instruments’ lõhkekatse seadmed on ideaalne lahendus. Meie seadmed tagavad, et teie pakendid vastavad regulatiivsetele ootustele ja toimivad veatult surve all.

KKK-d

1. Millised tööstusharud kasutavad tavaliselt ASTM F1140 katsetamist?Sellised tööstusharud nagu meditsiiniseadmed, farmaatsiatooted, toidupakendidja elektroonika tuginevad sageli ASTM F1140 katsetele, et tagada pakendi terviklikkus.

2. Kas rõhu lagunemise katse on osa standardist ASTM F1140?Kuigi ASTM F1140 ei sisalda ametlikult, on rõhu langemise meetod kasutatakse sageli selle kõrval kui mittedestruktiivne alternatiiv lekke tuvastamiseks.

3. Kuidas valida õige algrõhk roomavuskatseteks?Üldine suunis on kasutada 80% lõhkemisrõhu kohta roomavuskatsete jaoks ja 90% roomamise ja purunemise katsete jaoks.

4. Kas ASTM F1140 katsed võimaldavad tuvastada tihendi tugevust?Mitte otseselt. ASTM F1140 hindab veakindlus, samas kui tihendi tugevust hinnatakse tavaliselt kasutades ASTM F88.