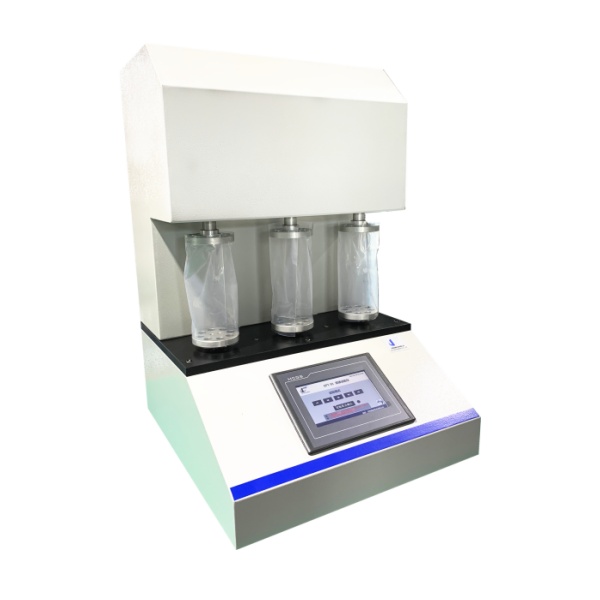

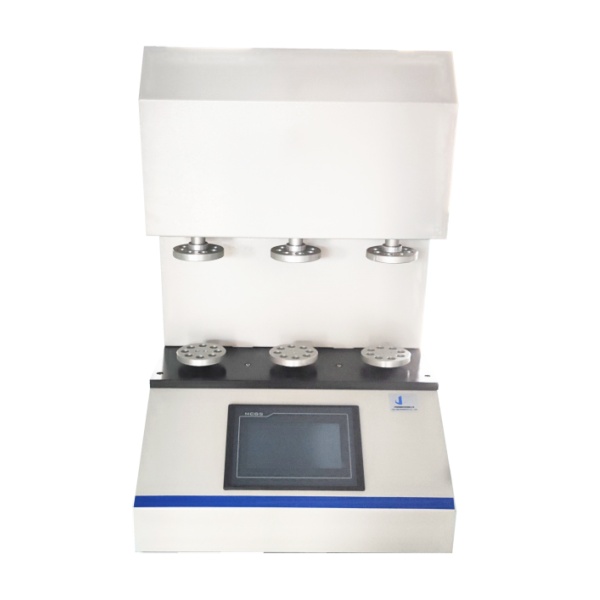

GFT Gelbo Flex Tester

- Standardne: ASTM F392

- Tootja: rakuinstrumendid

- Rakendused: pakkematerjalid, meditsiiniseadmete materjalid, farmaatsiatestid, liimid, tekstiilid, paberist ja papist mahutid ja palju muud.

- Kohandamine: Saadaval spetsiaalsete testimisnõuete ja automatiseerimise teisenduste jaoks

Introduction of Gelbo Flex Tester

The Gelbo Flex Tester is a specialized instrument designed to evaluate the flex durability and mechanical integrity of flexible materials such as barrier films, laminates, and coated fabrics. By simulating real-world twisting and compressive deformation, this tester provides critical insights into the resistance of packaging and coated materials to pinhole formation, crackingja barrier property degradation. Standards such as ASTM F392 ja ISO 7854 define the testing methods that ensure accuracy, repeatability, and international comparability.

The Gelbo Flex Tester, sometimes referred to as a rumple flex tester või flex tester, operates by subjecting test specimens to simultaneous twisting and compressing motions. This combined action reproduces the mechanical stress flexible packaging materials experience during filling, sealing, transportation, and storage.

The test method, commonly known as the Gelbo test method, evaluates a material’s ability to maintain integrity under cyclic deformation. Materials that fail this test often develop microscopic pinholes or cracks that compromise the package’s barrier performance against oxygen, moisture, or gas transmission.

Principle of the Gelbo Flex and Related Standards

Two primary international standards govern flex durability evaluation: ASTM F392 ja ISO 7854.

ASTM F392, titled Standardne tava elastsete tõkematerjalide konditsioneerimiseks elastse vastupidavuse tagamiseks, specifies test conditions for assessing the resistance of flexible packaging materials to flex-induced pinholes and barrier failures. In this method, specimens undergo repeated flexing at 45 cycles per minute, involving a 440° twist combined with a 65 mm horizontal motion. The test is conducted under standard conditions of 23 ± 2°C ja 50 ± 5% relative humidity. Depending on the desired conditioning level, test cycles may range from 20 to 2700, corresponding to levels A through E.

ISO 7854, Rubber- or plastics-coated fabrics — Determination of resistance to damage by flexing, defines three methods of flex testing. Method C, known as the crumple/flex method, closely resembles the Gelbo principle. Here, a cylindrical specimen is subjected to oscillating twist and axial compression, simulating real-life flex stress for coated fabrics, medical materials, and technical textiles.

Together, these standards establish the Gelbo flex procedure as the global benchmark for paindekindluse testimine.

How the Gelbo Flex Tester Works

The Gelbo Flex Tester (for example, the GFT Flex Durability Tester by Rakuinstrumendid) operates with high precision to replicate ASTM and ISO flexing motions.

- Proovi ettevalmistamine: Standard samples are 200 × 280 mm, cut in both machine and transverse directions.

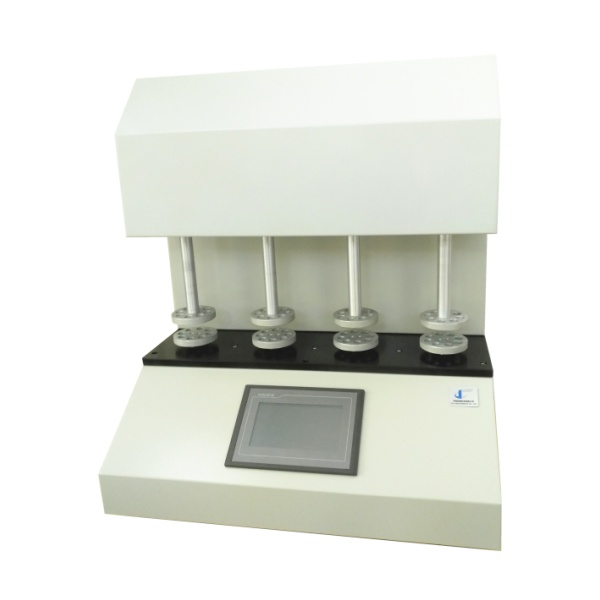

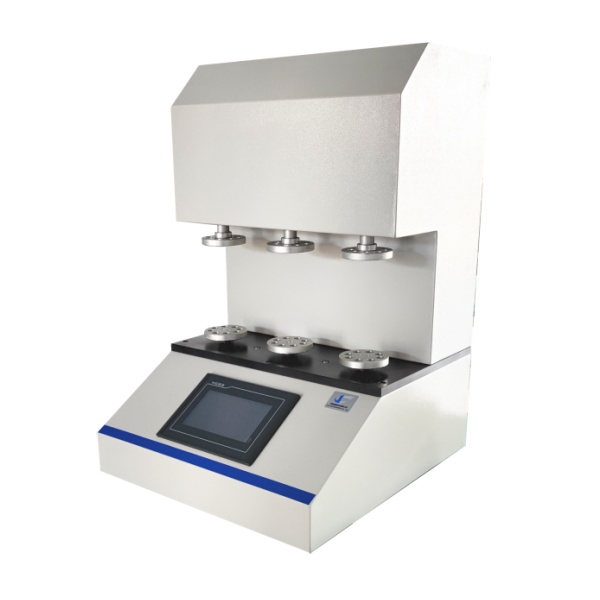

- Mounting: Samples are clamped or adhered to the tester’s mandrels, forming a cylindrical shape for simultaneous twisting and compression.

- Flexing Cycle: The tester executes a 440° twist during the first 90 mm of stroke, followed by a 65 mm linear compression, at a consistent 45 cycles per minute.

- Mode Selection: Users can select from five programmable test modes (A–E) to suit different material types or test objectives.

- Result Evaluation: After conditioning, specimens are inspected for pinholes, cracks, or barrier degradation using OTR (Oxygen Transmission Rate), WVTR (Water Vapor Transmission Rate), or GTR tests.

This controlled process allows laboratories and quality control teams to quantify a material’s flex resistance and predict its performance under real-world mechanical stress.

Key Features and Main Parameter

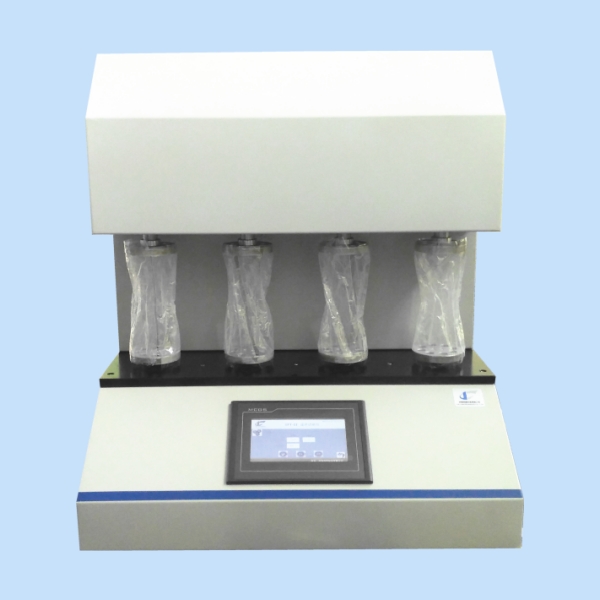

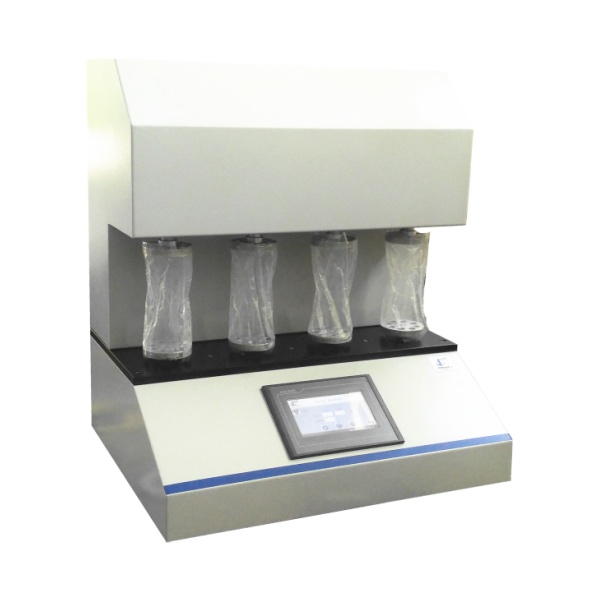

The GFT Gelbo Flex Tester series from Rakuinstrumendid offers advanced technology designed for high precision and ease of use:

- PLC Control & Touchscreen Interface – Ensures accurate motion control, user-friendly operation, and data repeatability.

- Multiple Test Stations – Available with three or four stations for parallel testing and comparative analysis.

- Programmable Test Conditions – Supports ASTM F392 modes A–E for versatile testing from quick screening (20 cycles) to endurance evaluation (2700 cycles).

- Durable Mechanical Design – Engineered for long-term stability and compliance with ASTM F392 ja ISO 7854 standarditele.

- Enhanced Data Reliability – Supports post-test evaluation of barrier integrity, pinhole formation, and mechanical strength changes.

| GFT Gelbo Flex Durability Tester | ||

| Parameter | GFT-02 Model | GFT-01 Model |

| Paindlik nurk | 440° (90 mm) või 400° (80 mm) | |

| Mahutavus | 3.5 N.m | 2,5 Nm |

| Horisontaalne löök | 155 mm või 80 mm | |

| Jaamad | 3 | 4 |

| Proovi suurus | 280 mm x 200 mm | |

| Võimsus | 110-220V | |

Applications of Gelbo Flex Testing

Gelbo flex testing is essential in industries where flexible materials must retain barrier integrity and aesthetic quality after repeated handling or mechanical stress. Key application areas include:

- Flexible Packaging for food, pharmaceuticals, and medical devices

- Coated Fabrics and Films for industrial, textile, and outdoor uses

- Adhesive Laminates ja composite structures

- Kvaliteedikontroll in R&D laboratories ja certification agencies

By identifying weak points early, manufacturers can improve material formulation, coating technology, and lamination processes.

KKK-d

V: Cell Instrumentsi Gelbo Flex Testeril on ainulaadne segu täppistehnikast ja uuenduslikest disainifunktsioonidest. Alates selle intuitiivsest kasutajaliidest kuni täiustatud automatiseerimisvõimalusteni on kõik aspektid täpselt läbi töötatud, et optimeerida jõudlust ja kasutuskogemust. Lisaks eristab selle ühilduvus paljude materjalide ja tööstusharudega mitmekülgse lahendusena paindlikkuse testimise vajadustele.

V: Allutades materjalidele range paindkatse, aitab painduvuse vastupidavuse tester tuvastada nõrkusi ja võimalikke tõrkepunkte arendusprotsessi alguses. See ennetav lähenemine võimaldab tootjatel tegeleda probleemidega enne nende eskaleerumist, mille tulemuseks on vastupidavamad, töökindlamad ja lõppkokkuvõttes kvaliteetsemad tooted.

V: Absoluutselt! Gelbo Flex Tester on loodud sobima mitmesuguste suuruste ja kujunditega, pakkudes testimisel paindlikkust ja mitmekülgsust. Olenemata sellest, kas töötate väikeste, õrnade kilede või suuremate, mahukamate materjalidega, saab meie tester hõlpsasti kohaneda teie konkreetsete testimisnõuetega.

V: Paindliku vastupidavuse testeri puhul on täpsus ülimalt tähtis. Läbi hoolika kalibreerimise ja tugeva konstruktsiooni tagame, et iga katse annab ühtsed ja usaldusväärsed tulemused. Lisaks on meie tester loodud väliste tegurite minimeerimiseks, mis võivad testi tulemusi mõjutada, suurendades veelgi täpsust ja korratavust.

V: Ettevõttes Cell Instruments on meie prioriteediks klientide rahulolu ja tugi. Meie spetsiaalne tehnilise toe meeskond on valmis abistama kasutajaid küsimuste, murede või tehniliste väljakutsetega, millega nad kokku puutuvad. Olenemata sellest, kas vajate abi seadistamisel, kalibreerimisel või tõrkeotsingul, on meie eksperdid siin, et pakkuda kiiret ja tõhusat tuge, et tagada teie testimisprotsesside tõrgeteta kulgemine

Viide

ASTM F392 Standardne tava elastsete tõkematerjalide konditsioneerimiseks elastse vastupidavuse tagamiseks