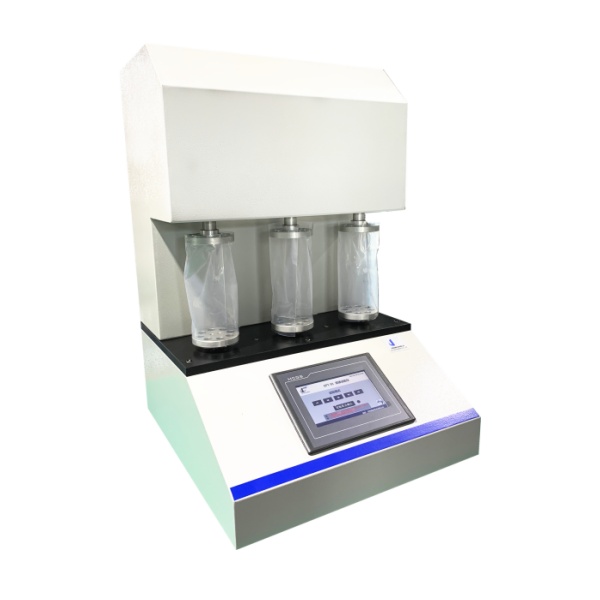

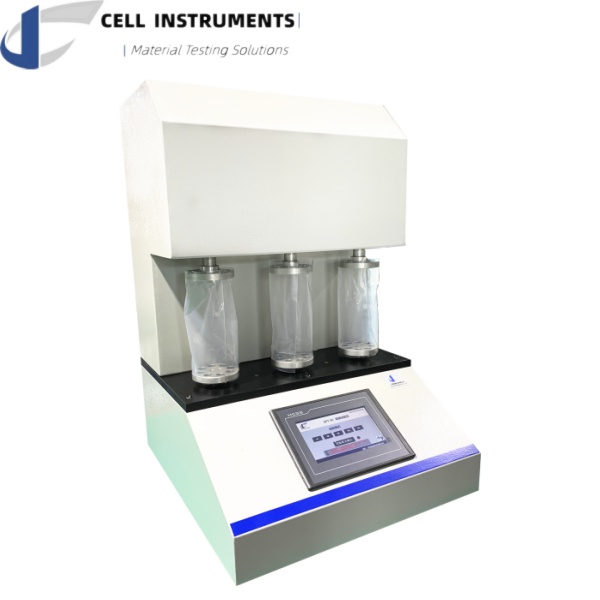

Pengenalan Penguji Fleksibilitas Gelbo

Itu Penguji Gelbo Flex adalah instrumen khusus yang dirancang untuk mengevaluasi daya tahan yang fleksibel dan integritas mekanis bahan fleksibel seperti film penghalang, laminasi, dan kain berlapis. Dengan mensimulasikan puntiran dunia nyata dan deformasi tekan, penguji ini memberikan wawasan penting tentang ketahanan kemasan dan bahan berlapis terhadap formasi lubang jarum, retak, Dan degradasi properti penghalang. Standar seperti ASTM F392 Dan ISO 7854 menentukan metode pengujian yang memastikan akurasi, pengulangan, dan komparabilitas internasional.

Itu Penguji Gelbo Flexkadang-kadang disebut sebagai penguji kelenturan rumple atau penguji fleksibelberoperasi dengan membuat spesimen uji melakukan gerakan memutar dan mengompresi secara simultan. Tindakan gabungan ini mereproduksi tekanan mekanis yang dialami bahan kemasan fleksibel selama pengisian, penyegelan, pengangkutan, dan penyimpanan.

Metode pengujian, umumnya dikenal sebagai metode Metode uji Gelbomengevaluasi kemampuan material untuk mempertahankan integritas di bawah deformasi siklik. Bahan yang gagal dalam pengujian ini sering kali mengalami lubang kecil atau retakan mikroskopis yang mengganggu kinerja penghalang kemasan terhadap transmisi oksigen, kelembapan, atau gas.

https://www.youtube.com/watch?v=HDpqg4jkaeAPrinsip Gelbo Flex dan Standar Terkait

Dua standar internasional utama mengatur evaluasi ketahanan lentur: ASTM F392 Dan ISO 7854.

ASTM F392, berjudul Praktik Standar untuk Pengondisian Bahan Penghalang Fleksibel untuk Daya Tahan Fleksibelmenetapkan kondisi pengujian untuk menilai ketahanan bahan kemasan fleksibel terhadap lubang kecil yang diinduksi pelenturan dan kegagalan penghalang. Dalam metode ini, spesimen mengalami pelenturan berulang kali pada 45 siklus per menit, yang melibatkan Memutar 440° dikombinasikan dengan Gerakan horizontal 65 mm. Pengujian dilakukan dalam kondisi standar 23 ± 2°C Dan Kelembaban relatif 50 ± 5%. Tergantung pada tingkat pengkondisian yang diinginkan, siklus pengujian dapat berkisar dari 20 hingga 2700, sesuai dengan level A sampai E.

ISO 7854, Kain berlapis karet atau plastik - Penentuan ketahanan terhadap kerusakan dengan cara melenturkanmendefinisikan tiga metode pengujian kelenturan. Metode C, yang dikenal sebagai metode crumple/flexsangat mirip dengan prinsip Gelbo. Di sini, spesimen silinder dikenakan putaran berosilasi dan kompresi aksialyang mensimulasikan tegangan lentur dalam kehidupan nyata untuk kain berlapis, bahan medis, dan tekstil teknis.

Bersama-sama, standar-standar ini menetapkan prosedur fleksibel Gelbo sebagai tolok ukur global untuk pengujian daya tahan lentur.

Cara Kerja Penguji Gelbo Flex

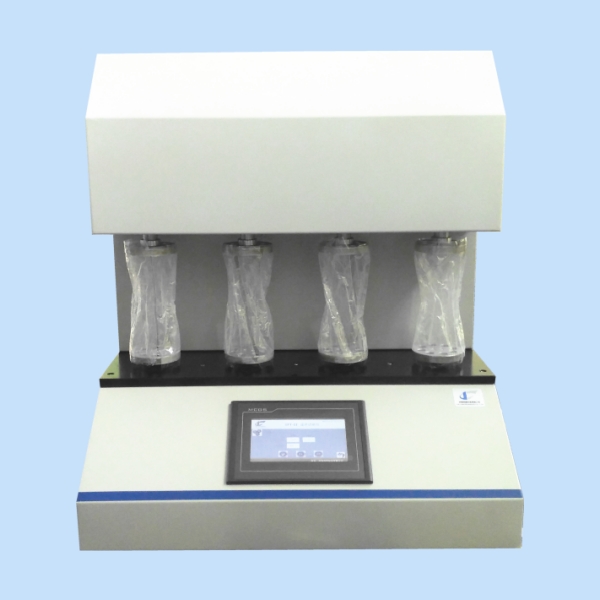

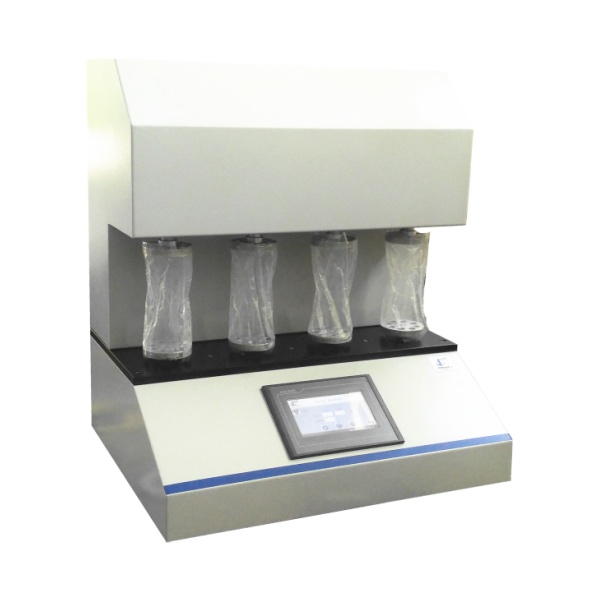

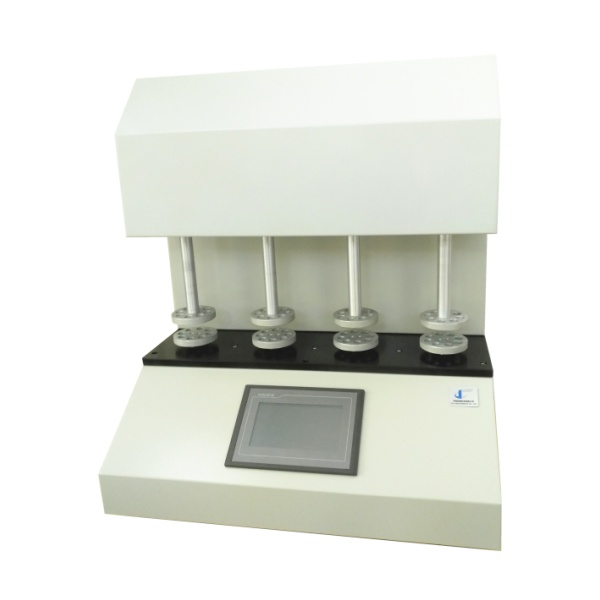

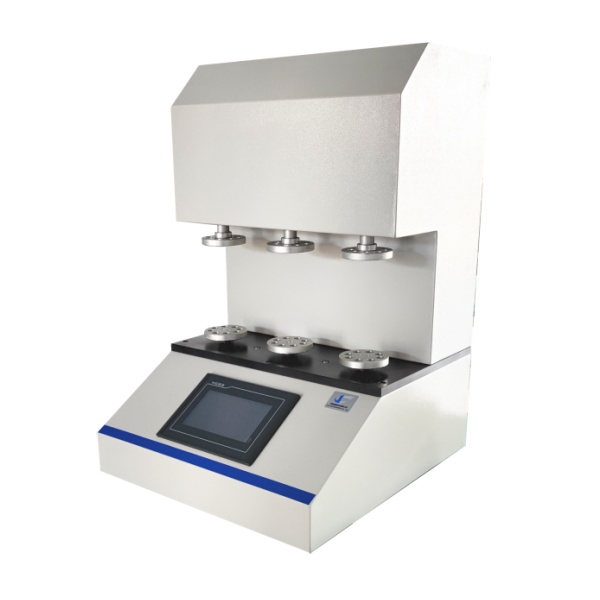

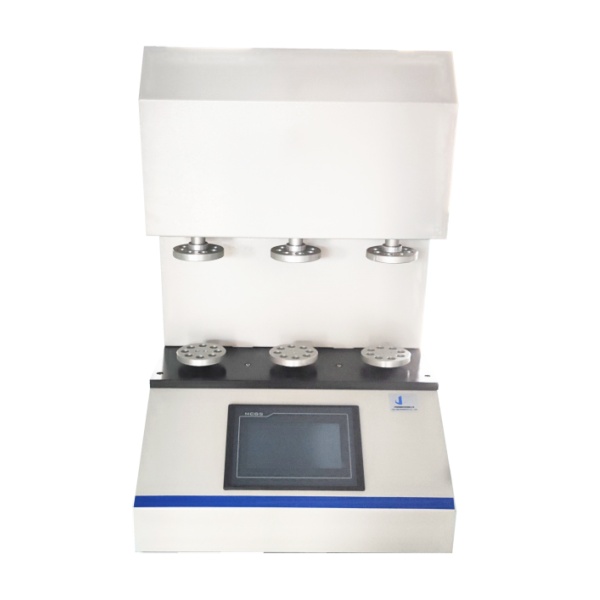

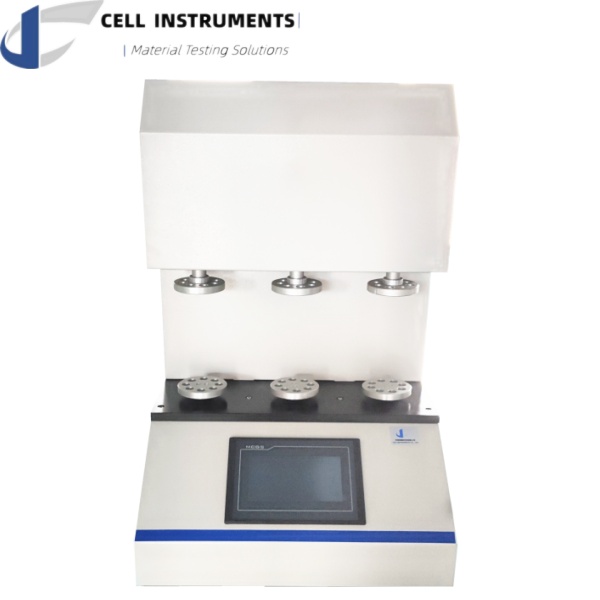

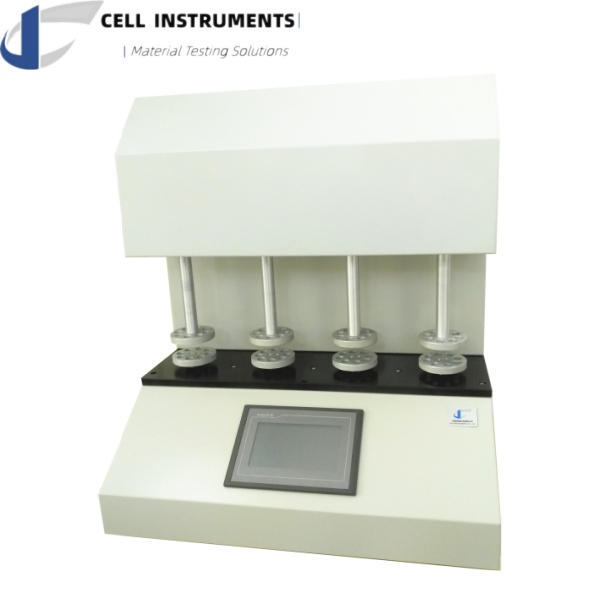

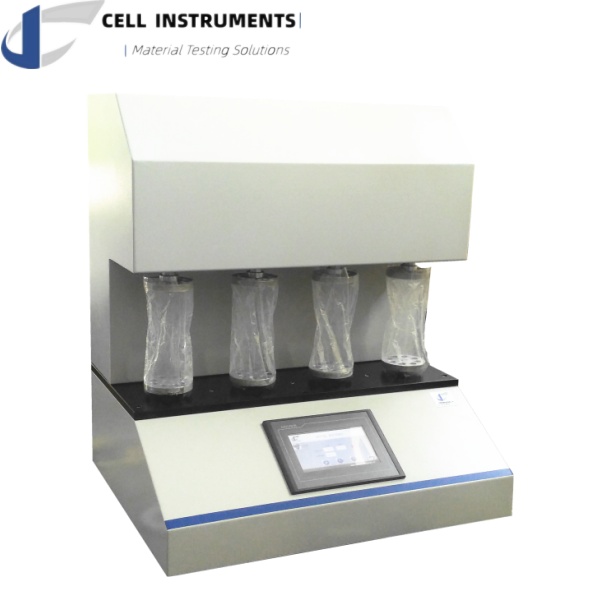

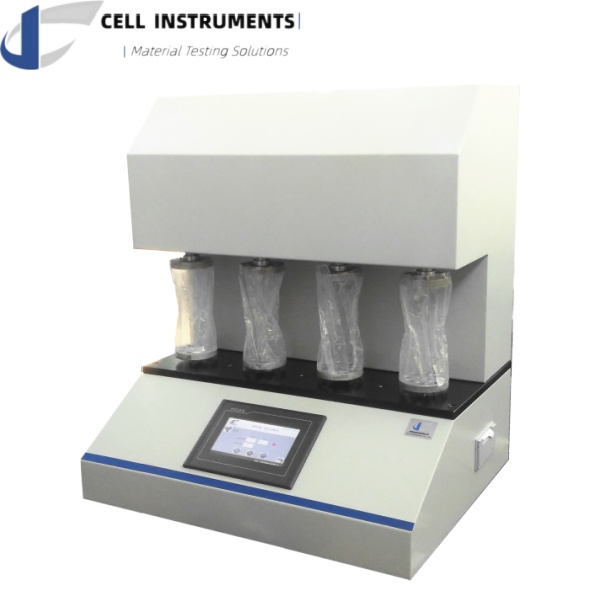

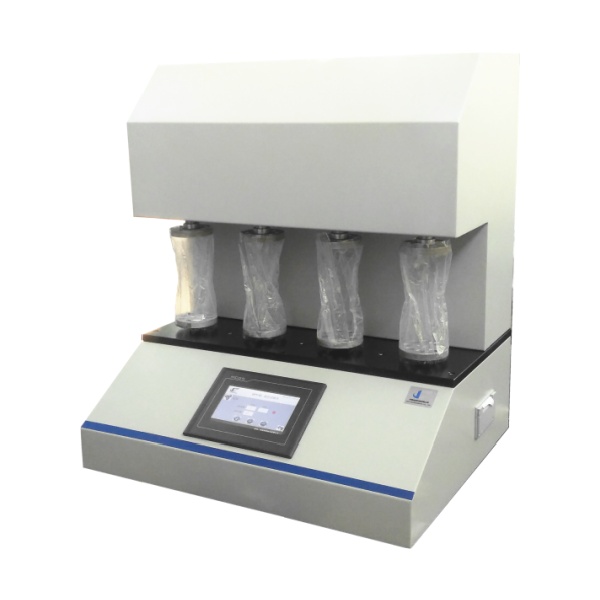

Itu Penguji Gelbo Flex (sebagai contoh, tombol Penguji Daya Tahan Lentur GFT oleh Instrumen Sel) beroperasi dengan presisi tinggi untuk mereplikasi gerakan pelenturan ASTM dan ISO.

- Persiapan Sampel: Sampel standar adalah 200 × 280 mmmemotong ke arah mesin dan arah melintang.

- Pemasangan: Sampel dijepit atau ditempelkan pada mandrel penguji, membentuk bentuk silinder untuk puntiran dan kompresi secara simultan.

- Siklus Pelenturan: Penguji mengeksekusi Memutar 440° selama 90 mm stroke pertama, diikuti oleh Kompresi linier 65 mmsecara konsisten 45 siklus per menit.

- Pemilihan Mode: Pengguna dapat memilih dari lima mode uji yang dapat diprogram (A-E) agar sesuai dengan jenis material atau tujuan pengujian yang berbeda.

- Evaluasi Hasil: Setelah pengkondisian, spesimen diperiksa apakah ada lubang kecil, retakan, atau degradasi penghalang menggunakan OTR (Laju Transmisi Oksigen), WVTR (Laju Transmisi Uap Air)atau GTR tes.

Proses terkontrol ini memungkinkan laboratorium dan tim kendali mutu untuk mengukur kandungan material. ketahanan lentur dan memprediksi kinerjanya di bawah tekanan mekanis dunia nyata.

Fitur Utama dan Parameter Utama

Itu Penguji GFT Gelbo Flex seri dari Instrumen Sel menawarkan teknologi canggih yang dirancang untuk presisi tinggi dan kemudahan penggunaan:

- Kontrol PLC & Antarmuka Layar Sentuh - Memastikan kontrol gerakan yang akurat, pengoperasian yang mudah digunakan, dan pengulangan data.

- Beberapa Stasiun Uji - Tersedia dengan tiga atau empat stasiun untuk pengujian paralel dan analisis komparatif.

- Kondisi Uji yang Dapat Diprogram - Mendukung mode ASTM F392 A-E untuk pengujian serbaguna mulai dari penyaringan cepat (20 siklus) hingga evaluasi daya tahan (2700 siklus).

- Desain Mekanis yang Tahan Lama - Dirancang untuk stabilitas jangka panjang dan sesuai dengan ASTM F392 Dan ISO 7854 standar.

- Keandalan Data yang Ditingkatkan - Mendukung evaluasi post-test dari integritas penghalangpembentukan lubang jarum, dan perubahan kekuatan mekanis.

| Penguji Daya Tahan GFT Gelbo Flex | ||

| Parameter | Model GFT-02 | Model GFT-01 |

| Sudut Fleksibel | 440° (90 mm) atau 400° (80 mm) | |

| Kapasitas | 3,5 Nm | 2,5 Nm |

| Goresan Horisontal | 155 mm atau 80 mm | |

| Stasiun | 3 | 4 |

| Ukuran Sampel | Ukuran 280 x 200 mm | |

| Kekuatan | Tegangan 110~220V | |

Aplikasi Pengujian Gelbo Flex

Pengujian fleksibilitas Gelbo sangat penting dalam industri di mana bahan fleksibel harus mempertahankan integritas penghalang dan kualitas estetika setelah penanganan berulang atau tekanan mekanis. Area aplikasi utama meliputi:

- Kemasan Fleksibel untuk makanan, obat-obatan, dan peralatan medis

- Kain dan Film yang Dilapisi untuk keperluan industri, tekstil, dan penggunaan di luar ruangan

- Laminasi Perekat Dan struktur komposit

- Kontrol Kualitas di Laboratorium R&D Dan lembaga sertifikasi

Dengan mengidentifikasi titik-titik lemah sejak dini, produsen dapat meningkatkan formulasi bahan, teknologi pelapisan, dan proses laminasi.

Tanya Jawab Umum

T: Apa yang membuat alat uji ketahanan lentur ini menonjol dibandingkan peralatan uji lentur lain di pasaran?A: Gelbo Flex Tester dari Cell Instruments menawarkan perpaduan unik antara rekayasa presisi dan fitur desain inovatif. Dari antarmuka pengguna yang intuitif hingga kemampuan otomatisasinya yang canggih, setiap aspek dibuat dengan cermat untuk mengoptimalkan kinerja dan pengalaman pengguna. Selain itu, kompatibilitasnya di berbagai bahan dan industri menjadikannya sebagai solusi serbaguna untuk kebutuhan pengujian lentur.

T: Bagaimana penguji berkontribusi dalam meningkatkan kualitas dan keandalan produk?A: Dengan melakukan pengujian lentur yang ketat pada material, penguji ketahanan lentur membantu mengidentifikasi kelemahan dan titik kegagalan potensial di awal proses pengembangan. Pendekatan proaktif ini memungkinkan produsen mengatasi masalah sebelum masalah tersebut memburuk, sehingga menghasilkan produk yang lebih tangguh, andal, dan pada akhirnya, berkualitas lebih tinggi.

T: Apakah penguji daya tahan lentur dapat mengakomodasi berbagai ukuran dan bentuk sampel?A: Tentu saja! Gelbo Flex Tester dirancang untuk mengakomodasi berbagai ukuran dan bentuk sampel, menawarkan fleksibilitas dan keserbagunaan dalam pengujian. Baik Anda bekerja dengan film kecil dan halus atau material yang lebih besar dan lebih tebal, alat uji kami dapat beradaptasi untuk memenuhi persyaratan pengujian spesifik Anda dengan mudah.

T: Bagaimana penguji memastikan hasil pengujian yang akurat dan dapat diulang?J: Presisi adalah hal terpenting dalam penguji ketahanan lentur. Melalui kalibrasi yang cermat dan konstruksi yang kokoh, kami memastikan bahwa setiap pengujian menghasilkan hasil yang konsisten dan dapat diandalkan. Selain itu, penguji kami dirancang untuk meminimalkan faktor eksternal yang dapat memengaruhi hasil pengujian, yang selanjutnya meningkatkan akurasi dan pengulangan.

T: Tingkat dukungan teknis apa yang tersedia bagi pengguna Gelbo Flex Tester?J: Di Cell Instruments, kami mengutamakan kepuasan dan dukungan pelanggan. Tim dukungan teknis kami yang berdedikasi siap membantu pengguna dengan pertanyaan, masalah, atau tantangan teknis apa pun yang mungkin mereka hadapi. Baik Anda memerlukan bantuan untuk pengaturan, kalibrasi, atau pemecahan masalah, para ahli kami siap memberikan dukungan yang cepat dan efektif untuk memastikan proses pengujian Anda berjalan lancar.

Referensi

ASTM F392 Praktik Standar untuk Pengondisian Bahan Penghalang Fleksibel untuk Daya Tahan Fleksibel