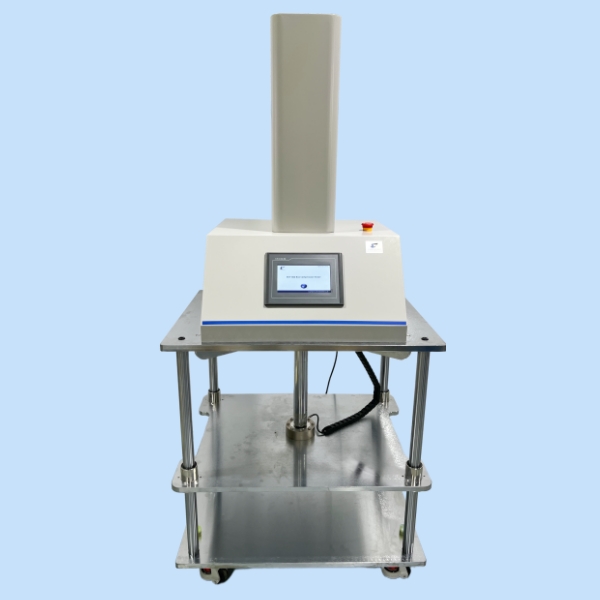

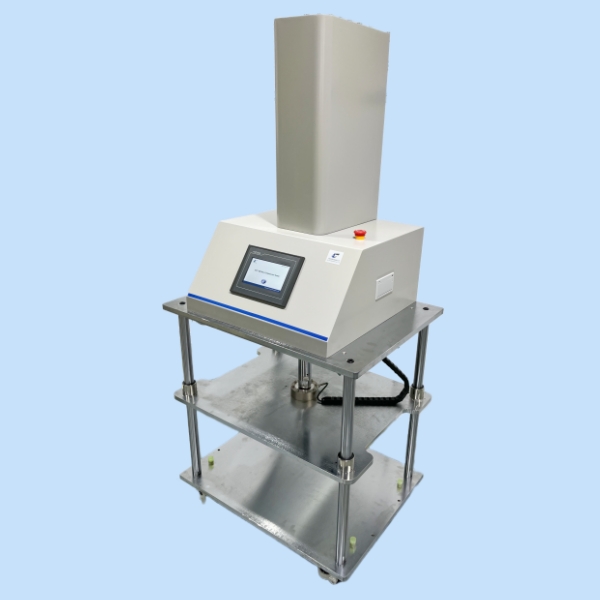

Q1: 箱の圧縮試験は何のために行われるのですか?

A1: 箱の圧縮試験は、梱包材の圧縮強度を測定し、梱包材が積み重ねや輸送時の圧力に耐えられることを確認するものです。

Q2: 箱型圧縮試験機は、さまざまな種類の容器に対応できますか?

A2: はい、当社の箱圧縮試験機は、段ボール、プラスチック、木製、複合容器を、充填済みでも空でも試験することができます。

Q3: 箱型圧縮試験が最も恩恵を受けるのはどの業界ですか?

A3:包装、食品、医療、医薬品、接着剤、繊維、物流などの業界では、包装の信頼性を確認するために箱の圧縮試験を利用している。

Q4: 箱型圧縮試験機の精度はどのくらいですか?

A4:Cell Instruments」テスターは、誤差±1%の高精度ロードセルセンサーを使用しており、信頼性の高い結果を保証します。

Q5: 試験はグローバルスタンダードに準拠していますか?

A5: はい、Cell Instrumentsのボックス圧縮試験機はISO、ASTM、TAPPI、JIS、GB/T規格に適合しており、国際的なコンプライアンスと信頼性を備えています。