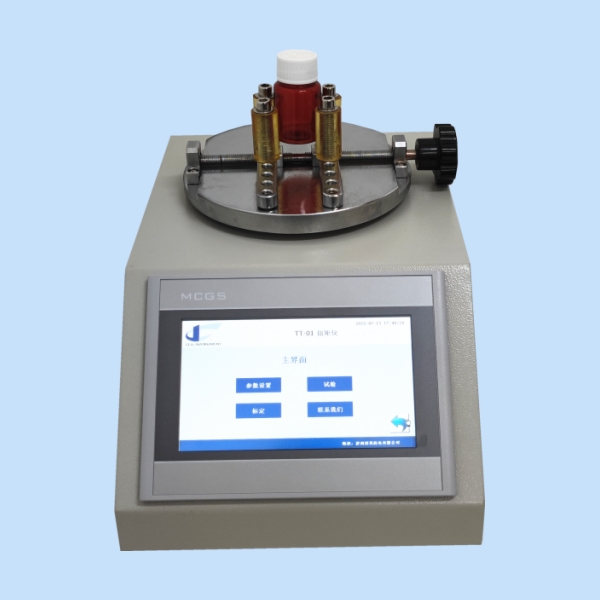

I. 수동 캡 토크 테스터 소개

The Manual Cap Torque Tester is a highly reliable device used to measure the torque required to open and lock caps on various types of packaging, such as medicine bottles, PET bottles, spout bags, and flexible tube packages. In packaging industries, understanding and controlling cap torque is critical. If the torque is too high, the container can be difficult to open for the consumer, or it may damage the packaging. On the other hand, insufficient torque can result in product leakage or compromised packaging integrity during transportation.

By providing precise measurements, the Manual Cap Torque Tester helps manufacturers meet industry standards and ensure customer satisfaction. Its use is widespread in industries like food, beverages, pharmaceuticals, and personal care products, where packaging integrity and ease of use are paramount.

II. 수동 캡 토크 테스터의 적용

포장 품질을 위한 캡 토크 테스트

The Manual Cap Torque Tester is essential in quality control, especially in high-volume production environments. This device measures the force required to open or lock caps, enabling manufacturers to optimize production lines to ensure consistent packaging quality. Whether used for testing caps on medicine bottles, PET bottles, or flexible tubes, the tester plays a pivotal role in ensuring that the torque values applied during the packaging process are accurate and meet product-specific standards.

예를 들어, 제약 산업에서 올바른 토크는 의약품 병이 운송 중에 안전하게 닫혀 있지만 소비자가 쉽게 열 수 있도록 하는 데 필수적입니다. 음료 산업에서 정확한 캡 토크는 유출이나 누출을 방지하는 동시에 제품의 신선도와 안전을 보장합니다.

III. 수동 캡 토크 테스터의 주요 기술적 특징

1. 높은 정밀도와 안정성

The Manual Cap Torque Tester is known for its precision and stability, making it an ideal choice for rigorous quality control environments. It offers a high degree of accuracy with a resolution of 0.001 Nm, ensuring that even the smallest variations in torque values are captured.

2. 유연한 측정 단위

One of the standout features of the Manual Cap Torque Tester is its ability to display torque measurements in multiple units, including Kgf.cm, N.cm, daN.cm, Inch.lbs, and N.m. This flexibility makes it suitable for a wide range of applications, from pharmaceuticals to food and beverage packaging. The device also allows for peak value retention, ensuring that operators can easily record the highest torque force applied during testing.

3. 사용자 친화적인 디자인

With a simple, user-friendly design, the Manual Cap Torque Tester offers an intuitive interface that is easy to operate. The tester is equipped with a touch screen for easy operation and a PLC-controlled system that ensures industrial-level stability during testing. This combination of precision, stability, and ease of use makes the device a reliable tool in any production setting.

IV. 수동 캡 토크 테스터의 테스트 방법

캡 토크 테스트 절차

The process of testing with the Manual Cap Torque Tester is straightforward but vital for ensuring packaging quality. The sample container is first securely fastened onto the device’s clamp. Then, the cap is manually opened or closed, while the tester records the torque force required. A sensor connected to the clamp measures the torque, which is then displayed on the screen in the desired unit.

테스터는 개방 및 잠금 힘을 모두 측정할 수 있어 다양한 포장 유형에서 사용하기에 이상적입니다. 테스트 후 피크 값은 자동으로 유지되어 데이터를 쉽게 기록할 수 있으므로 테스트 중에 적용된 가장 높은 토크가 정확하게 캡처됩니다.

V. 주요 표준 준수

The Manual Cap Torque Tester is designed to meet several international standards, making it a reliable tool for quality control in various industries. The following standards outline the requirements for cap torque testing and packaging integrity:

- ASTM D2063: 이 표준은 플라스틱 캡과 마개의 토크를 시험하는 방법을 규정합니다.

- ASTM D3198: 캡과 클로저의 토크 유지력을 결정하는 방법을 정의하고, 시간이 지나도 제대로 밀봉 상태를 유지하도록 보장합니다.

- ASTM D3474: 다양한 조건에서의 토크 테스트를 포함한 포장재의 환경 테스트를 다룹니다.

- GB/T 17876: A Chinese standard for cap torque testing, ensuring compliance with regional packaging requirements.

- BB/T 0025 & BB/T 0034: Industry-specific standards for cap testing, particularly for food and beverage packaging.

VI. 주요 기술 사양

| 테스트 범위 | 10 Nm(또는 필요에 따라) |

| 정확성 | 1% FS |

| 해결 | 0.001나노미터 |

| 클램프 범위 | Φ5mm~φ170mm |

| 전원 AC | 110~220V |

자주 묻는 질문

Q1: What is a Manual Cap Torque Tester used for? A: The Manual Cap Torque Tester is used to measure the opening and locking forces of caps on bottles, jars, and other containers to ensure packaging quality and safety.

Q2: Why is cap torque testing important? A: Cap torque testing ensures that the right amount of force is applied when sealing or opening containers, preventing product leakage, ensuring consumer safety, and enhancing user experience.

Q3: What industries benefit most from cap torque testing? A: Cap torque testing is essential in industries such as food and beverages, pharmaceuticals, personal care products, and any industry where packaging integrity is important.

Q4: What standards does the Manual Cap Torque Tester comply with? A: The tester complies with several standards, including ASTM D2063, ASTM D3198, ASTM D3474, GB/T 17876, and BB/T 0025 & BB/T 0034.

Q5: Can the tester measure both opening and locking forces? A: Yes, the Manual Cap Torque Tester can measure both the force required to open a cap and the force needed to lock it, making it a versatile tool for packaging quality control.