Mop Coefficient of Friction Testing

The mop coefficient of friction testing plays a crucial role in evaluating the surface interaction between mop materials and flooring substrates. This measurement helps determine how slippery or resistant a mop is under real-world conditions, which directly impacts safety, cleaning effectiveness, and material durability. Whether in healthcare, hospitality, or industrial settings, a reliable friction test helps manufacturers produce mops that meet performance and safety standards.

Understanding Coefficient of Friction in Mop Applications

The coefficient of friction (COF) refers to the resistance force encountered when one surface moves across another. It is quantified using the formula:

μ = f ÷ N,

where:

- μ is the coefficient of friction,

- f is the frictional force,

- N is the normal (perpendicular) force.

There are two key types of COF measured:

- Static COF (μs): Measures the force required to start movement.

- Kinetic COF (μd): Measures the force required to maintain movement.

In mop applications:

- A higher static COF may indicate better grip on the floor but reduced ease of movement.

- A lower kinetic COF helps ensure smooth gliding without compromising cleaning efficiency.

Why Mop Coefficient of Friction Testing Matters

Accurately evaluating mop friction characteristics ensures:

- Slip resistance, especially in wet environments like hospitals or food service areas.

- Cleaning performance consistency across floor types and surface treatments.

- Product quality optimization, helping manufacturers control fabric choices, coatings, and structure.

Friction can be affected by factors such as:

- Mop fiber composition (cotton, microfiber, blended yarn)

- Surface treatments like antibacterial coatings or water-repellent finishes

- Floor conditions (wet, dry, polished, tiled, etc.)

Lab Quality Control Testing and Mop Quality Testing Solution

For consistent product quality, manufacturers rely on lab quality control testing processes. Integrating mop coefficient of friction testing into routine inspection ensures that each batch of mops meets safety and usability expectations.

As part of a mop quality testing solution, the COF test provides quantifiable results that correlate directly with user experience. This approach supports:

- Regulatory compliance

- Consumer safety assurance

- Design improvement and benchmarking

- Performance validation under simulated real-use conditions

Ląstelių instrumentai offers turnkey testing systems that simplify the evaluation of COF across mop samples under various test conditions.

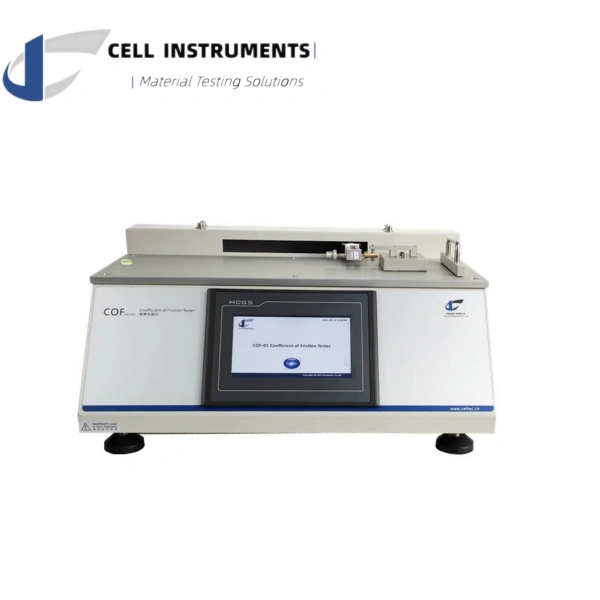

Recommended Equipment: COF-01 Coefficient of Friction Tester

For mop coefficient of friction testing, Cell Instruments’ COF-01 Trinties koeficiento testeris is a versatile, precision-engineered solution designed for both static and kinetic COF measurements. It supports materials like woven fabrics, non-wovens, plastic sheets, and mop cloths.

Pagrindinės funkcijos:

- PLC-controlled system with intuitive HMI touch screen

- Real-time test curve display and automatic data logging

- Complies with ISO and ASTM test standards

- Adaptable sled weight and test speed for different materials

- Data output via RS232 and optional software for analysis

- Built-in microprinter for immediate result documentation

Customization available for mop-specific fixtures and sled dimensions (e.g., wide surface contact areas, unique mounting for mop heads).

Test Standards and Best Practices

Mop COF testing should follow established methodologies to ensure comparability and reproducibility. Commonly referenced standards for surface interaction testing include:

- ASTM D1894: Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

- ISO 8295: Plastics — Film and Sheeting — Determination of the Coefficients of Friction

For mop-specific applications, test parameters (sled weight, speed, surface type) may require adjustment. Cell Instruments supports custom protocol development to meet specific industry or internal QA requirements.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cell Instruments Coefficient Of Friction Tester

At Ląstelių instrumentai, we specialize in delivering precise testing solutions tailored for the cleaning product industry. With growing demand for safety and quality, this test is increasingly vital for lab quality control testing ir mop quality testing solution development.

Mop coefficient of friction testing is a fundamental part of modern lab quality control testing and an essential mop quality testing solution. By identifying the optimal balance between glide and grip, manufacturers can deliver safer and more effective cleaning products.

Using Cell Instruments’ COF-01 Trinties koeficiento testeris, professionals can confidently evaluate and optimize mop performance. With customizable solutions and technical expertise, we help ensure that your testing meets the highest industry standards.