I. Rankinio dangtelio sukimo momento testerio įvadas

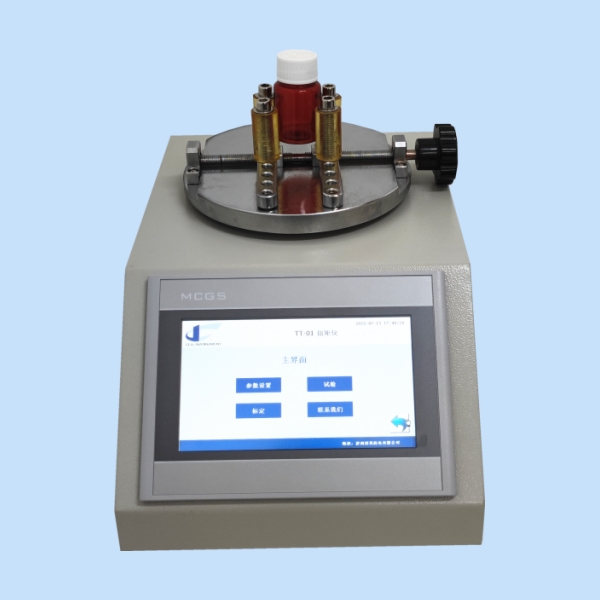

The Manual Cap Torque Tester is a highly reliable device used to measure the torque required to open and lock caps on various types of packaging, such as medicine bottles, PET bottles, spout bags, and flexible tube packages. In packaging industries, understanding and controlling cap torque is critical. If the torque is too high, the container can be difficult to open for the consumer, or it may damage the packaging. On the other hand, insufficient torque can result in product leakage or compromised packaging integrity during transportation.

By providing precise measurements, the Manual Cap Torque Tester helps manufacturers meet industry standards and ensure customer satisfaction. Its use is widespread in industries like food, beverages, pharmaceuticals, and personal care products, where packaging integrity and ease of use are paramount.

II. Rankinio dangtelio sukimo momento testerio taikymas

Bandomas dangtelio sukimo momentas, siekiant nustatyti pakuotės kokybę

The Manual Cap Torque Tester is essential in quality control, especially in high-volume production environments. This device measures the force required to open or lock caps, enabling manufacturers to optimize production lines to ensure consistent packaging quality. Whether used for testing caps on medicine bottles, PET bottles, or flexible tubes, the tester plays a pivotal role in ensuring that the torque values applied during the packaging process are accurate and meet product-specific standards.

Pavyzdžiui, farmacijos pramonėje tinkamas sukimo momentas yra gyvybiškai svarbus siekiant užtikrinti, kad vaistų buteliukai transportavimo metu liktų saugiai uždaryti, bet vartotojai galėtų juos lengvai atidaryti. Gėrimų pramonėje tikslus dangtelio sukimo momentas užtikrina produkto šviežumą ir saugumą, išvengiant išsiliejimo ar nuotėkio.

III. Pagrindinės rankinio dangtelio sukimo momento testerio techninės savybės

1. Didelis tikslumas ir stabilumas

The Manual Cap Torque Tester is known for its precision and stability, making it an ideal choice for rigorous quality control environments. It offers a high degree of accuracy with a resolution of 0.001 Nm, ensuring that even the smallest variations in torque values are captured.

2. Lankstūs matavimo vienetai

One of the standout features of the Manual Cap Torque Tester is its ability to display torque measurements in multiple units, including Kgf.cm, N.cm, daN.cm, Inch.lbs, and N.m. This flexibility makes it suitable for a wide range of applications, from pharmaceuticals to food and beverage packaging. The device also allows for peak value retention, ensuring that operators can easily record the highest torque force applied during testing.

3. Patogus dizainas

With a simple, user-friendly design, the Manual Cap Torque Tester offers an intuitive interface that is easy to operate. The tester is equipped with a touch screen for easy operation and a PLC-controlled system that ensures industrial-level stability during testing. This combination of precision, stability, and ease of use makes the device a reliable tool in any production setting.

IV. Rankinio dangtelio sukimo momento testerio bandymo metodai

Dangtelio sukimo momento bandymo procedūra

The process of testing with the Manual Cap Torque Tester is straightforward but vital for ensuring packaging quality. The sample container is first securely fastened onto the device’s clamp. Then, the cap is manually opened or closed, while the tester records the torque force required. A sensor connected to the clamp measures the torque, which is then displayed on the screen in the desired unit.

Testeris gali išmatuoti atidarymo ir užrakinimo jėgas, todėl jis idealiai tinka naudoti įvairių tipų pakuotėse. Po bandymo didžiausia vertė automatiškai išsaugoma, kad būtų lengviau įrašyti duomenis, užtikrinant, kad būtų tiksliai užfiksuotas didžiausias bandymo metu pritaikytas sukimo momentas.

V. Pagrindinių standartų laikymasis

The Manual Cap Torque Tester is designed to meet several international standards, making it a reliable tool for quality control in various industries. The following standards outline the requirements for cap torque testing and packaging integrity:

- ASTM D2063: Šis standartas apibrėžia plastikinių dangtelių ir uždorių sukimo momento bandymo metodus.

- ASTM D3198: apibrėžia dangtelių ir dangtelių sukimo momento išlaikymo nustatymo metodus, užtikrinančius, kad laikui bėgant jie išliktų tinkamai užsandarinti.

- ASTM D3474: Apima pakavimo medžiagų aplinkosaugos bandymus, įskaitant sukimo momento bandymus skirtingomis sąlygomis.

- GB/T 17876: A Chinese standard for cap torque testing, ensuring compliance with regional packaging requirements.

- BB/T 0025 & BB/T 0034: Industry-specific standards for cap testing, particularly for food and beverage packaging.

VI. Pagrindinės techninės specifikacijos

| Bandymų diapazonas | 10 Nm (arba pagal poreikį) |

| Tikslumas | 1% FS |

| Rezoliucija | 0,001 Nm |

| Gnybtų diapazonas | Φ5 mm ~ φ170 mm |

| Maitinimas AC | 110-220V |

DUK

Q1: What is a Manual Cap Torque Tester used for? A: The Manual Cap Torque Tester is used to measure the opening and locking forces of caps on bottles, jars, and other containers to ensure packaging quality and safety.

Q2: Why is cap torque testing important? A: Cap torque testing ensures that the right amount of force is applied when sealing or opening containers, preventing product leakage, ensuring consumer safety, and enhancing user experience.

Q3: What industries benefit most from cap torque testing? A: Cap torque testing is essential in industries such as food and beverages, pharmaceuticals, personal care products, and any industry where packaging integrity is important.

Q4: What standards does the Manual Cap Torque Tester comply with? A: The tester complies with several standards, including ASTM D2063, ASTM D3198, ASTM D3474, GB/T 17876, and BB/T 0025 & BB/T 0034.

Q5: Can the tester measure both opening and locking forces? A: Yes, the Manual Cap Torque Tester can measure both the force required to open a cap and the force needed to lock it, making it a versatile tool for packaging quality control.