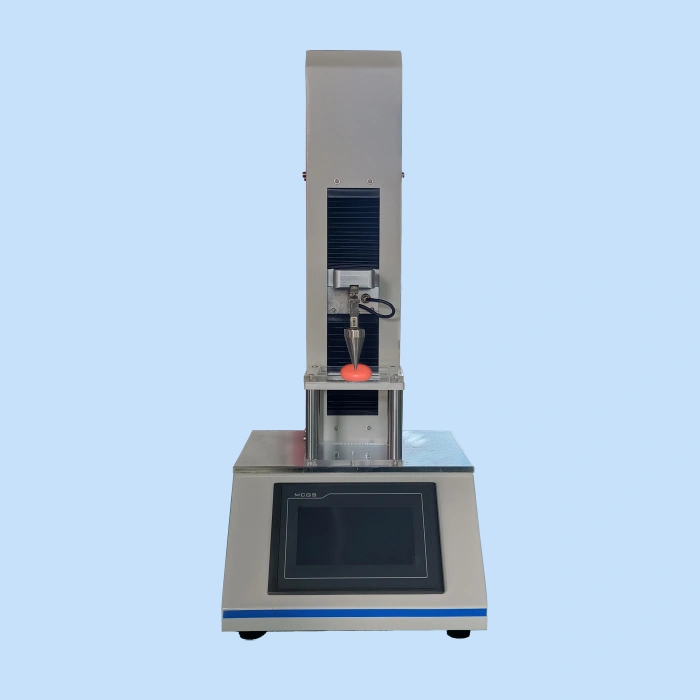

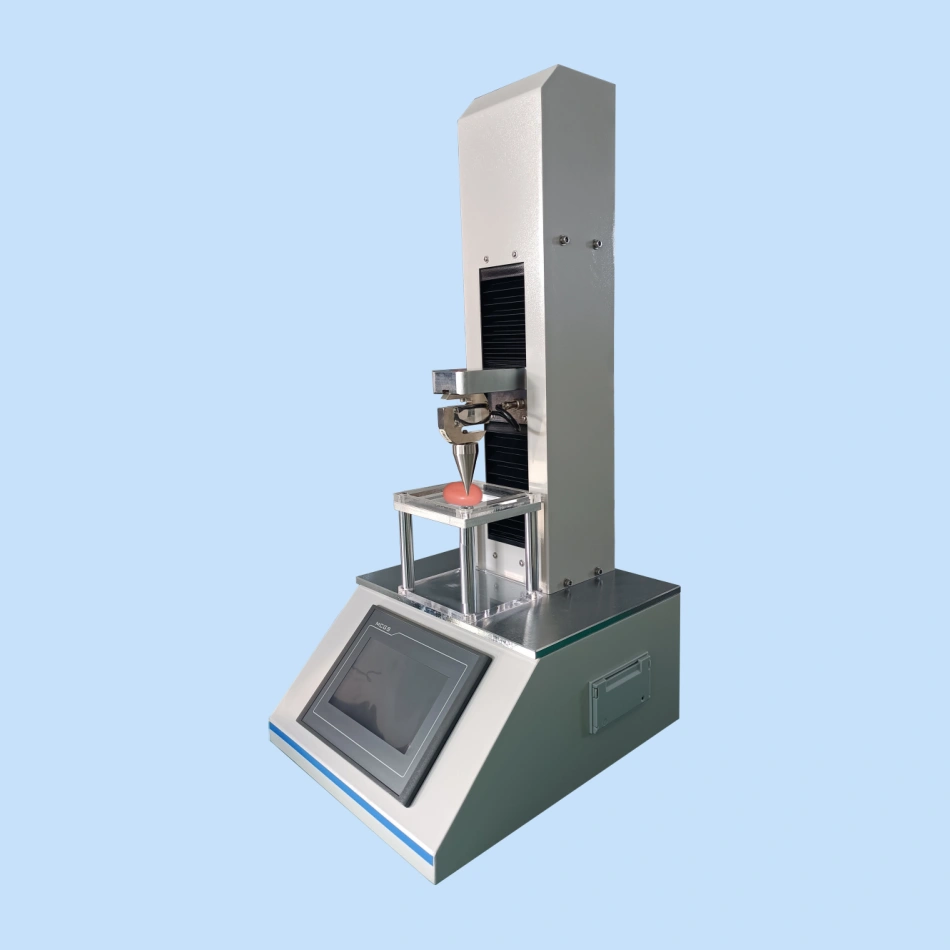

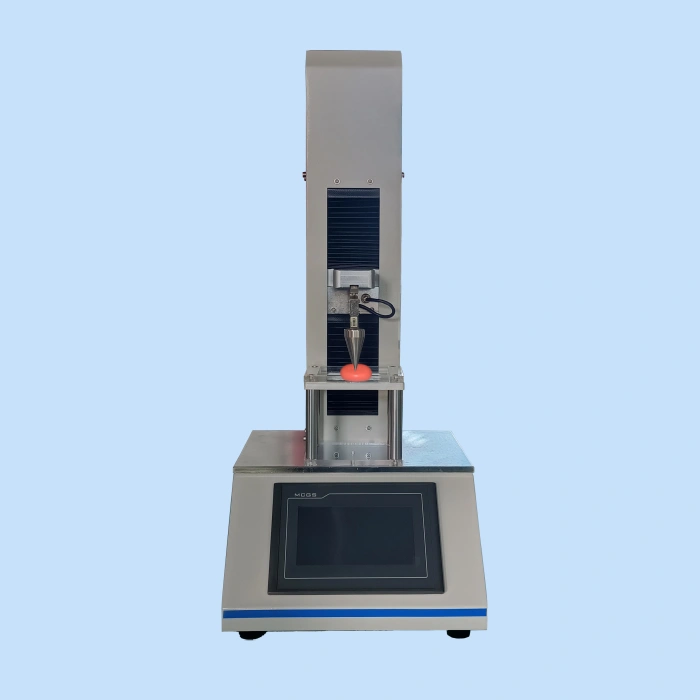

A soap penetration tester provides an efficient and standardized approach to measuring soap hardness. By supporting ASTM D1321 test principles, it enables accurate evaluation of soap hardness while improving quality control confidence.

For manufacturers and laboratories seeking dependable, repeatable, and easy-to-use testing equipment, Cell Instruments offers soap penetration testing solutions that combine technical reliability with practical usability—making them well suited for modern soap production and research environments.