Bloom Strength of Soft Gelatin Capsule Testing

Measuring the bloom strength of soft gelatin capsule is essential in pharmaceutical quality control. It directly reflects the mechanical integrity and consistency of gelatin material, ensuring capsules meet both regulatory standards and consumer expectations. This article explores the fundamentals of bloom strength, how to test it, and why choosing reliable equipment like the CHT-01 Gelatin Capsule Hardness Tester from Cell Instruments is crucial for dependable results.

Understanding Bloom Strength in Gelatin Capsules

Bloom strength is a measure of the firmness or gel strength of gelatin, which directly influences the elasticity, rupture resistance, and dissolution behavior of soft gelatin capsules. The term originates from the Bloom test, which measures the weight in grams needed by a standard plunger to depress the surface of a gelatin gel by 4 mm under specific conditions (usually at 10°C after 17–18 hours of gelation).

In the context of soft gelatin capsules, high bloom strength generally indicates a firmer and more resilient capsule shell, contributing to improved product stability, mechanical resistance during packaging, and better control over drug release.

Importance of Bloom Strength Testing in Pharmaceutical Quality Control

The bloom strength of soft gelatin capsule must be consistently monitored for the following reasons:

- Product Quality Assurance: Ensures the structural integrity of the capsule.

- Regulatory Compliance: Meets pharmacopeial standards like USP and EP.

- Formulation Stability: Identifies variations in raw gelatin batches.

- Consumer Safety: Ensures capsules don’t rupture prematurely or dissolve too slowly.

These quality benchmarks are especially critical for temperature-sensitive or moisture-sensitive drugs.

Instruments Used: Bloom Strength Of Soft Gelatin Capsule Test

Bloom Tester – Measuring Gel Strength of Gelatin

A bloom tester evaluates the mechanical strength of a gelatin gel, which is closely tied to capsule performance. This test involves:

- Preparing gelatin solution (6.67% w/w),

- Conditioning the gel at 10°C ±0.1°C for 16-18 hours,

- Applying a standard plunger (12.7 mm) to measure the resistance (in grams).

Although this test focuses on raw gelatin properties, it’s vital for upstream material evaluation in capsule production.

Gelatin Capsule Hardness Test – Evaluating Final Product

Once capsules are formed, their hardness and resistance to force need to be validated using a gelatin capsule hardness test. This test involves applying force to the capsule shell until deformation or rupture occurs, simulating stress during packaging, storage, and ingestion.

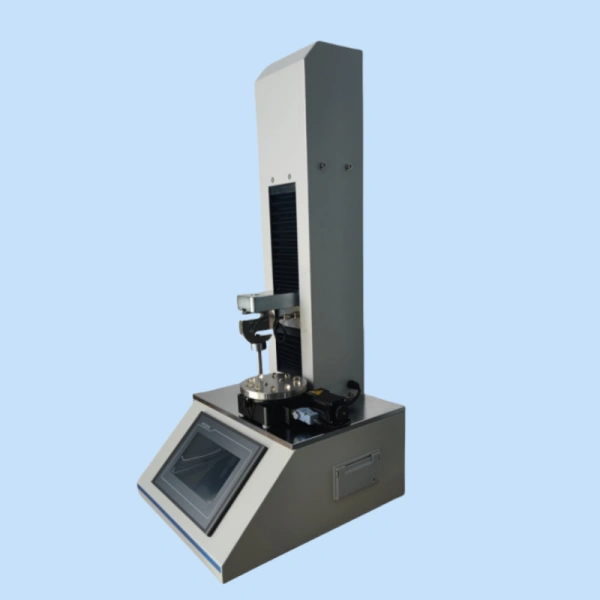

One of the most effective tools for this is the CHT-01 Gelatin Capsule Hardness Tester from Cell Instruments.

Procedure for Testing Gelatin Capsule Hardness

Sample Preparation

- Clean capsules and condition them at 20–25°C with 50% RH.

- Ensure no visible defects before testing.

Test Execution

- Calibration: Perform calibration using certified weights or displacement gauges.

- Setup: Load capsule horizontally between clamps.

- Force Application: Start the test at a preset speed (e.g., 100 mm/min).

- Measurement: Record the force (N) at rupture or maximum deformation.

Data Analysis

- Use peak force as the hardness index.

- Compare across batches to assess gelatin consistency or detect formulation issues.

- Link trends to bloom strength of raw gelatin when troubleshooting variations.

Role in Regulatory Compliance and R&D

By correlating bloom tester results with gelatin capsule hardness test data, quality control teams can establish critical quality attributes (CQAs) that support ICH Q8–Q10 compliance, and build a strong quality-by-design (QbD) framework. Additionally, the CHT-01 supports method development for novel formulations, making it ideal for R&D labs.

Choosing the Right Bloom Tester

To perform accurate quality control tests for soft gelatin capsules, the CHT-01 by Cell Instruments offers precision, usability, and full compliance with industry needs.

Key Features Include:

- High Accuracy: Precision ball screw and stepper motor for ±0.5% F.S. accuracy.

- Versatility: Customizable clamps for various capsule shapes and sizes.

- Intuitive Interface: 7-inch touchscreen and PLC controls.

- Data Output: Real-time display, microprinter, and RS232 connectivity.

- Multi-Test Programs: Measure force, peak load, and displacement.

- Automatic Features: Auto return, data statistics, and overload protection.

With this device, laboratories and production facilities can efficiently conduct repeatable and compliant gelatin capsule hardness tests, aligned with both bloom strength requirements and pharmacopeial standards.

Contact Us Get Bloom Testing Solution

The loop tack test method is essential for quantifying the instant bonding capability of pressure-sensitive adhesives. By following recognized standards like PSTC-16, ASTM D6195, and FINAT FTM 9, and utilizing precision equipment such as the Cell Instruments LTT-01, laboratories can ensure reliable, repeatable, and standard-compliant adhesive performance evaluations.

For organizations seeking customization, automation, or expert support, Cell Instruments offers full technical solutions tailored to your material testing needs across packaging, medical, pharmaceutical, and beyond.