Test ściskania kartonu: Ocena wytrzymałości dla niezawodnych opakowań

Zrozumienie znaczenia testu kompresji kartonu

Ten test kompresji kartonu odgrywa decydującą rolę w ocenie jakości opakowań, zwłaszcza w przypadku pudeł z tektury falistej stosowanych w transporcie, magazynowaniu i dystrybucji. Ponieważ kartony doświadczają nacisku podczas układania w stosy, wibracji, wilgotności otoczenia i długotrwałych sił obciążenia, producenci i inżynierowie jakości potrzebują naukowej metody określenia, czy karton może wytrzymać te naprężenia. Ten test zapewnia wiarygodne dane liczbowe dotyczące wytrzymałości na ściskanie, umożliwiając markom ulepszenie projektu opakowania, zmniejszenie liczby uszkodzeń produktów i zapewnienie bezpieczeństwa logistyki.

Cell Instruments koncentruje się na dostarczaniu profesjonalnych rozwiązań do testowania materiałów. Nasze systemy testowania pomagają inżynierom opakowań ocenić możliwość układania w stosy, zoptymalizować strukturę pudełka i spełnić normy regulacyjne lub specyficzne dla klienta.

Rola normy ASTM D642 w testach ściskania kartonów

ASTM D642 jest najbardziej uznaną międzynarodową normą określającą wytrzymałość na ściskanie pojemników opakowaniowych. Norma określa sposób pomiaru wytrzymałości na ściskanie w warunkach od góry do dołu, od krawędzi do krawędzi lub od narożnika do narożnika. Określa również specyfikacje maszyn, wymagania dotyczące obciążenia wstępnego, środowiska kondycjonowania, orientacje testowe i definicje uszkodzeń.

Norma ASTM D642 podkreśla kilka kluczowych elementów:

- Skrzynki mogą być testowane z zawartością lub bezw zależności od rzeczywistych warunków wysyłki.

- Testy mogą obejmować pełne pojemniki, puste pojemniki lub komponenty, co zapewnia elastyczność w opracowywaniu opakowań.

- Do testowania krawędzi i narożników wymagane są maszyny do ściskania z nieruchomą płytą, zapewniające dokładne przyłożenie naprężenia.

- Prędkość testowania musi mieścić się w zakresie 0,5 ± 0,1 in/minzapewniając spójność i powtarzalność.

Awaria jest zwykle definiowana jako 10% spadek od maksymalnego obciążenia lub osiągnięcie wstępnie zdefiniowanego limitu odkształcenia.

Włączenie normy ASTM D642 do rutynowych testów ściskania pomaga zachować spójność, usprawnić komunikację z klientami i spełnić globalne standardy łańcucha dostaw.

Jak działa test kompresji kartonu

Test kompresji kartonu symuluje rzeczywiste ciśnienie podczas przechowywania i transportu. Poniższe kroki przedstawiają standardowy przepływ pracy zgodny z praktykami branżowymi:

Przygotowanie i kondycjonowanie próbek

Wilgotność otoczenia znacząco wpływa na wytrzymałość tektury falistej. Dlatego próbki powinny być kondycjonowane zgodnie z uznanymi wytycznymi, takimi jak atmosfery symulujące tranzyt. Właściwe kondycjonowanie zapewnia wiarygodne i porównywalne wyniki.

Pozycjonowanie płyty i wstępne ładowanie

Karton należy umieścić na środku dolnej płyty dociskowej, aby uniknąć obciążenia mimośrodowego. Nawet niewielka niewspółosiowość może spowodować niedokładne wyniki lub uszkodzenie sprzętu. Niewielkie obciążenie wstępne - zwykle 50 lbf dla skrzynek jednościennych-Zapewnia, że obie płyty dociskowe w pełni stykają się z powierzchnią kartonu przed rozpoczęciem kompresji.

Kompresja do awarii

Płyta dociskowa ściska karton w sposób ciągły z wymaganą prędkością aż do uszkodzenia. Inżynierowie rejestrują obciążenie szczytowe, krzywą obciążenie-odkształcenie i zachowanie strukturalne. Wyniki te bezpośrednio odzwierciedlają możliwość układania kartonów w stosy i pozwalają menedżerom ds. jakości przewidywać wydajność magazynu.

Zastosowania i zalety testów ściskania kartonów

Test ściskania kartonu służy wielu celom:

- Optymalizacja projektu opakowania: Inżynierowie mogą dostosować grubość ścianki, gatunek materiału, typ rowka lub wzory kleju na podstawie danych testowych.

- Zapewnienie jakości łańcucha dostaw: Dokładne wartości wytrzymałości na ściskanie pomagają określić wysokość składowania w magazynie i zmniejszyć ryzyko zawalenia.

- Redukcja kosztów: Nadmiernie zaprojektowane kartony zwiększają koszty; niedostatecznie zaprojektowane kartony zwiększają uszkodzenia produktu. Testy kompresji zapewniają właściwą równowagę.

Zgodność z normami: Wielu dostawców opakowań musi udowodnić, że ich wydajność jest zgodna z wymaganiami klienta lub normami, takimi jak ASTM D642 lub ISO 12048.

Poprawiając wydajność opakowań, firmy przyczyniają się do bezpieczniejszego transportu, lepszej reputacji marki i mniejszego wpływu na środowisko.

Dlaczego warto wybrać tester kompresji skrzynek Cell Instruments?

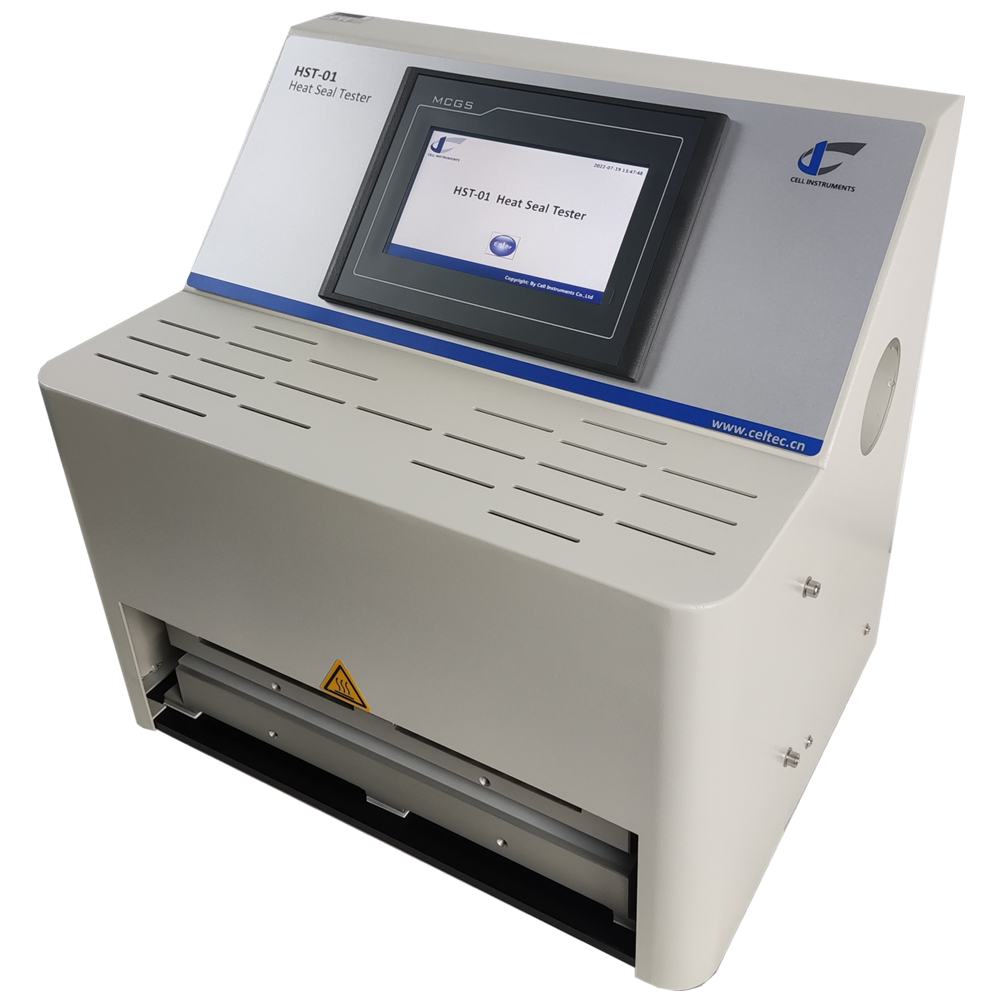

Cell Instruments zapewnia wysoką precyzję pudełkowe testery kompresji zaprojektowane specjalnie z myślą o dokładnych testach kompresji kartonów. Nasze systemy oferują:

- Ramy o wysokiej sztywności zapewniające stabilne obciążenie ściskające

- Duże płaskie płyty o doskonałej równoległości

- Opcjonalne płyty stałe lub obrotowe dla różnych orientacji testu

- Inteligentne systemy sterowania i wyświetlanie krzywej obciążenie-odkształcenie w czasie rzeczywistym

- Konfigurowalne konfiguracje testowe dla specjalnych formatów opakowań, dużych kartonów lub ciężkich ładunków jednostkowych

Zalety te umożliwiają laboratoriom, producentom opakowań i działom kontroli jakości uzyskanie spójnych i wiarygodnych wyników testów przy jednoczesnym spełnieniu wymagań normy ASTM D642. Dla użytkowników poszukujących automatyzacji, Cell Instruments oferuje również rozwiązania do testowania wielu próbek i kontroli jakości linii produkcyjnej.

Wniosek

Test ściskania kartonu dostarcza niezbędnych danych do zrozumienia wydajności kartonu pod naciskiem układania w stosy, pomagając specjalistom od opakowań projektować bezpieczniejsze i bardziej wydajne pojemniki transportowe. Dzięki wskazówkom zawartym w normie ASTM D642 i wsparciu zaawansowanego sprzętu testującego, firmy mogą znacznie poprawić niezawodność opakowań i zmniejszyć ryzyko logistyczne. Cell Instruments nadal wspiera globalnych producentów, dostarczając dokładne, stabilne i przyjazne dla użytkownika rozwiązania do testowania kompresji kartonów.

Jeśli chcesz zoptymalizować wydajność opakowania lub opracować niestandardowe rozwiązanie testowe, Cell Instruments jest gotowy do pomocy.