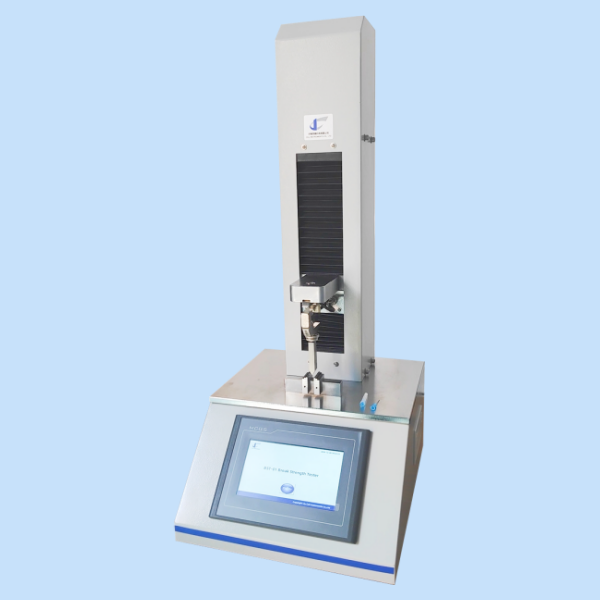

TS-01 Тестер жесткости труб

- Стандарт: ISO 9626

- Производитель: Клеточные инструменты

- Приложения: материалы для медицинских приборов, фармацевтические испытания и многое другое.

- Настройка: Доступно для специальных требований к тестированию и автоматизированным преобразованиям

Введение в тестер жесткости шприцевых трубок

Для специалистов в области производства медицинского оборудования, жесткость трубки шприца играет важнейшую роль в обеспечении надежности, безопасности и удобства использования подкожных игл. На сайте Тестер жесткости трубки шприцаспециально разработанный для оценки жесткости игольчатых трубок из нержавеющей стали, обеспечивает надежный метод контроля качества и соответствия стандартам. Этот прибор, например, Cell Instruments' TS-01, незаменим для выполнения требований, изложенных в ISO 9626.

Жесткость напрямую связана с механической целостностью. Трубки с недостаточной жесткостью могут перегибаться, ломаться или деформироваться во время использования, что создает риск травмы, неточного дозирования или загрязнения. И наоборот, слишком жесткая трубка может не обеспечить достаточной гибкости, что приведет к перелому или дискомфорту. Сайт Тестер жесткости трубки шприца Компания решает эти проблемы, обеспечивая точные, воспроизводимые измерения, соответствующие мировым стандартам.

ISO 9626 и стандарты испытаний на жесткость шприцевых трубок

ISO 9626в частности Приложение B, определяет стандартный метод испытания для измерения жесткости игольчатых трубок из нержавеющей стали. Этот длинный хвостовой ключ-Испытание по стандарту ISO 9626-это важно для производителей, которые должны демонстрировать соответствие международным нормам по медицинским изделиям.

В соответствии с ISO 9626 Приложение B:

- Трубка поддерживается на обоих концах, а к ее середине прикладывается усилие до 60 Н с помощью клиновидного плунжера.

- Полученное отклонение измеряется с точностью до 0,01 мм.

- Испытание гарантирует, что жесткость трубки находится в допустимых пределах для предполагаемого медицинского применения.

The Тестер жесткости трубки шприца Компания Cell Instruments разработана с учетом всех этих требований, что делает ее идеальным решением для групп контроля качества и регулирующих органов.

Механизм работы и структура тестера жесткости трубки шприца TS-01

The TS-01 Тестер жесткости шприцевых трубок использует надежную и точную систему, разработанную для минимизации ошибок измерения. В ней используются:

- А клиновидный плунжер с радиусом 1 мм, наклоненный под углом 60°, как указано в приложении B стандарта ISO 9626.

- А прецизионный тензодатчик и подвижная траверса для обеспечения точного приложения силы.

- А трубный поддон при котором образец находится непосредственно под плунжером.

Такая конфигурация имитирует условия испытаний, предусмотренные стандартом ISO, обеспечивая воспроизводимость и целостность данных.

Основные характеристики системы:

- ПЛК-управление и 7-дюймовый сенсорный экран HMI интерфейс

- Прецизионный шарико-винтовой привод для постоянного контроля скорости

- Переменная скорость от 1 до 500 мм/мин для проведения индивидуальных испытаний

- Измерение отклонения с высоким разрешением (0,01 мм)

- Защита от перегрузки для обеспечения безопасности оборудования и образцов

- Функция автоматического возврата посттест

- Встроенный микропринтер для немедленного документирования результатов

Принцип и методология испытаний

Принцип теста на жесткость прост, но научно обоснован:

- Позиционирование: Трубка шприца поддерживается с обоих концов на длине пролета, указанной в таблице 2 ISO 9626.

- Приложение силы: Плунжер прикладывает усилие вниз в средней точке с возможностью регулирования скорости (1-10 мм/мин для ISO 9626; до 500 мм/мин для настраиваемых испытаний).

- Измерение прогиба: Прибор измеряет прогиб трубки с точностью ±0,01 мм.

- Запись данных: Записывается и печатается такая информация, как размер трубки, материал, прогиб, скорость испытания и приложенное усилие.

Этот тест обеспечивает соответствие стандартам ISO и внутренним стандартам качества.

Почему стоит выбрать тестер жесткости шприцевых трубок TS-01 от Cell Instruments?

Компания Cell Instruments завоевала репутацию производителя точных, надежных и настраиваемых приборов. Сайт TS-01 Тестер жесткости шприцевых трубок предлагает исключительную точность и надежные функции, предназначенные для производства шприцев и лабораторий качества. Наша команда также поддерживает индивидуальные требования к испытаниям и решения для автоматизацииОбеспечение интеграции с существующими рабочими процессами в производстве упаковки, фармацевтических препаратов и медицинского оборудования.

Области применения и обслуживаемые отрасли

The Тестер жесткости трубки шприца широко используется в различных отраслях:

- Производство медицинского оборудования

- Фармацевтическое производство

- Упаковка для медицинских учреждений

- Лаборатории для проверки соответствия нормативным требованиям и тестирования

- Обеспечение качества для производителей игл

Проверяете ли вы безопасность продукции, встречаете ли ISO 9626 тестирование критериев или обеспечения механической надежности, TS-01 станет вашим оптимальным решением.