TAPPI T830

Ink Rub Test

TAPPI T830 is a widely recognized standard for evaluating the rub resistance of ink films and printed surfaces on container board and corrugated board. The test helps manufacturers, printers, and packaging professionals determine how well inks withstand rubbing, scuffing, or abrasion under different conditions. Since packaging often experiences friction during storage, shipping, and handling, this evaluation is critical to maintaining legibility, branding, and overall product quality.

In practice, TAPPI T830 serves not only as a technical guideline but also as a benchmark for comparing inks, coatings, and substrates. By following this method, quality control teams can ensure consistency, meet customer requirements, and avoid costly complaints related to poor print durability.

Importance of the Ink Rub Test

The ink rub test determines whether inks can endure mechanical stress without transferring, smearing, or fading. TAPPI T830 covers several variations, including:

- Dry rub – Evaluates abrasion resistance under normal conditions.

- Wet rub – Measures resistance when moisture is present.

- Wet bleed/transfer – Assesses the tendency of ink to transfer to blotting paper or cloth.

- Wet smear – Identifies smearing under moisture and pressure.

- Functional rub – Simulates real-world exposure, such as rubbing with oil, toothpaste, or other substances.

These assessments are vital for industries where packaging and labeling carry essential product and brand information. Strong rub resistance ensures the printed image remains intact, protecting both aesthetics and compliance with labeling regulations.

Ink Rub Test Procedure

The ink rub test procedure outlined in TAPPI T830 involves preparing samples, applying controlled rubbing forces, and evaluating results visually or with instruments.

- Sample preparation

- Select undamaged sections of container board or corrugated board.

- Cut specimens according to the specified dimensions.

- Ensure orientation follows the machine direction for consistency.

- Testing process

- Secure the printed sample and an unprinted counterpart under test blocks.

- Apply weight (commonly 2 lb or 4 lb) and preset the tester for a defined number of strokes.

- For wet rub, place drops of water on the printed surface before running the strokes.

- For wet bleed/transfer, use blotting paper or cotton cloth saturated with water.

- Evaluation

- Results are typically classified as pass or fail based on ink transfer or visible surface damage.

- Advanced evaluations may involve densitometers or spectrophotometers to quantify ink loss or color changes.

- The number of strokes until failure is often recorded for reference and comparison.

This structured approach ensures repeatability and comparability across different test runs.

Applications of TAPPI T830 in Industry

The TAPPI T830 method finds broad use across industries such as:

Packaging

Ensuring printed corrugated boxes maintain brand visibility during transport.

Food and beverages

Safeguarding product labels that carry regulatory and marketing information.

Pharmaceuticals

Preserving critical dosage and safety instructions.

Textiles and daily chemicals

Protecting design prints from fading or smearing.

Ink Abrasion Resistance Tester and Equipment

Accurate testing requires a rub test machine, also known as an ink abrasion resistance tester. These instruments simulate rubbing conditions under controlled speed, pressure, and motion.

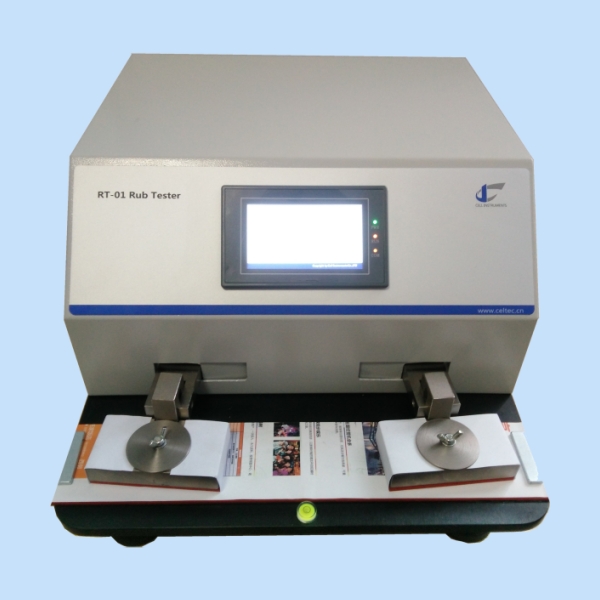

Cell Instruments offers the RT-01 Ink Rub Tester, designed for versatility and reliability. Key features include:

- Multiple test modes: dry rub, wet rub, wet bleed/transfer, wet smear, and functional rub.

- Adjustable speed range (20–120 cpm) for tailored testing conditions.

- Two test stations for improved efficiency.

- Precision rub circle control, ensuring consistent results.

- User-friendly PLC and touch screen interface.

By using advanced instruments like the RT-01, laboratories and factories can ensure compliance with TAPPI T830 while streamlining workflows and improving accuracy.

Contact Us Get TAPPI T830 Testing Solution

TAPPI T830 provides a reliable framework for assessing ink rub resistance on container board and corrugated board. By following its procedures, companies can safeguard print quality, reduce customer complaints, and maintain compliance. Whether performing a dry rub test or more specialized procedures like wet smear or functional rub, using a high-quality rub test machine is essential for dependable results.