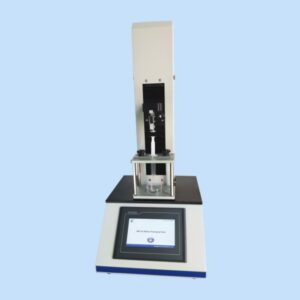

SSR-01 Syringe Sliding Resistance Tester

Bryt lös och glidkrafttestning

In syringe performance evaluation, bryta loss och testa glidkraft plays a crucial role in assessing the smoothness and reliability of the plunger movement. This test determines the force required to initiate and maintain the motion of the syringe piston, ensuring consistent drug delivery and patient safety.

Cell Instruments, a leading manufacturer of materials testing equipment, provides advanced break loose and glide force testing machines designed according to ISO 7886-1 standards. These instruments help manufacturers, laboratories, and quality control professionals ensure that their syringes meet international quality and performance requirements.

ISO 7886-1 and Syringe Performance

The international standard ISO 7886-1 specifies the requirements and test methods for sterile hypodermic syringes for single use. Annex E of the standard outlines the test method for determining the forces required to operate the piston, including both bryta loss kraft och gliding force.

- Break loose force refers to the initial force required to start the plunger movement.

- Gliding force represents the continuous force needed to maintain piston movement throughout the stroke.

These two parameters are critical indicators of syringe quality, influencing user comfort, injection accuracy, and drug flow stability. Excessive or inconsistent forces can result in jerky movement, dosage errors, or even syringe failure.

Principle of Break Loose and Glide Force Testing

—— ISO 7886-1 Annex E

De bryta loss och testa glidkraft process uses a mekanisk testmaskin to push the syringe plunger while measuring and recording the applied force. The test evaluates how smoothly the plunger operates under standardized conditions, such as temperature and displacement speed.

During the test:

- The syringe is filled with water maintained at (23 ± 5)°C.

- The syringe nozzle connects to a water reservoir at a controlled level.

- The testing machine moves the plunger at a constant rate of (100 ± 5) mm/min).

- The system records:

- De break loose force (Fs) – force required to start piston movement.

- De mean gliding force (F) – average force during steady plunger movement.

- De maximum force (Fmax) – peak force observed during movement.

These parameters are plotted as a force-displacement curve, providing clear visualization of syringe performance characteristics.

SSR-01 Syringe Sliding Resistance Tester

Cell Instruments offers precision-engineered break loose and glide force testing machines that comply with ISO 7886-1 and related pharmaceutical testing standards.

Key Features Include:

- Hög precision: Force accuracy up to 0.5% of full-scale reading.

- Wide Test Speed Range: Adjustable from 1 to 500 mm/min to accommodate various test conditions.

- Three-Force Measurement: Automatically captures break loose force, mean glide force, and maximum force.

- Användarvänligt gränssnitt: PLC-controlled with a 7-inch HMI touchscreen for seamless operation.

- Built-in Printer: Provides immediate test results for documentation and quality assurance.

- Overload Protection: Ensures long-term durability and operator safety.

Huvudparameter

| Lastcell | 200N (eller efter behov) |

| Testa hastighet | 1~500 mm/min |

| Noggrannhet | 0,01 mm |

| Driva | 110~220V |

Applications and Industry Impact

Break loose force and glide force testing is critical across multiple sectors:

- Medicinsk utrustning: Ensures syringe safety and usability for healthcare professionals and patients.

- Läkemedel: Verifies product consistency before distribution.

- Regulatory Testing: Provides data necessary for compliance with ISO 7886-1 testing requirements.

- Kvalitetskontroll: Helps manufacturers maintain high production standards and reduce defect rates.

Thanks to its precision and adherence to ISO protocols, the SSR-01 is ideal for syringe manufacturers, pharmaceutical companies, och quality inspection agencies.

Varför välja cellinstrument?

As an experienced manufacturer specializing in material testing and automation, Cell Instruments provides complete solutions for syringe break loose and glide force testing. We combine high-precision engineering, customizable software, and expert technical support to help clients meet stringent industry standards.

Bryt dig loss och test av glidkraft is an essential part of syringe quality verification according to ISO 7886-1. It directly affects usability, safety, and regulatory compliance. By using professional testing instruments from Cellinstrument, laboratories and manufacturers can achieve reliable, accurate, and reproducible results—enhancing both product performance and customer confidence.