ISO 8295

Testmetod för friktionskoefficient

De ISO 8295 standard plays a critical role in evaluating the slip properties of plastic films, essential for packaging performance, processing efficiency, and product safety. By determining the Friktionskoefficient (COF) between film surfaces or between film and other materials, ISO 8295 ensures that manufacturers can maintain consistent product quality and packaging reliability.

Få offertISO 8295 Is Important for Plastic Film Manufacturers

For film producers and packaging converters, ISO 8295 testing is a cornerstone of kvalitetskontroll. The slip behavior of plastic films—whether polyethylene, polypropylene, polyester, or multilayer laminates—can change due to:

- Additive migration (e.g., slip agents like erucamide)

- Surface treatments (e.g., corona, plasma)

- Environmental exposure (aging or humidity)

- Handling conditions during shipping and processing

Accurate COF measurements help ensure the film performs well throughout its lifecycle—from converting and printing to sealing and final application.

Coefficient of Friction of Film and COF of Plastic Film in Packaging

De coefficient of friction of film, often referred to as COF of plastic film, measures how easily one layer of film slides over another. This property significantly influences machinability on form-fill-seal equipment, pouching lines, and automated stacking processes. Poor slip characteristics can lead to equipment jams or misfeeds, while overly slippery films may cause sealing problems or product misalignment.

ISO 8295 specifically provides a standardized method for testing both statisk och dynamic coefficients of friction:

- Statisk COF (μs) measures the resistance at the start of motion.

- Dynamic COF (μd) measures resistance during continued sliding.

This distinction is vital for applications such as vertical form fill seal (VFFS) where packaging films must initiate and maintain smooth movement under load.

Overview of ISO 8295 Testing Method

ISO 8295 outlines a laboratory method for evaluating slip properties by sliding a sled across a test specimen placed on a horizontal test surface. The apparatus generally includes:

- A släde with a standardized weight (typically 200g ±29g) and contact area.

- A motorized stage or a tensile testing machine to apply uniform motion.

- A force-measuring device to record frictional resistance.

Key parameters defined in ISO 8295 include:

- Test speed: Normally 100 mm/min ±10 mm/min

- Contact time before sliding: 15 seconds

- Sample conditioning: 23°C, 50% RH for at least 16 hours per ISO 291

Measurements are typically taken over multiple film pairs to ensure statistical accuracy. The results help assess uniformity across a production batch or compare formulations with varying slip agents.

https://youtu.be/NUgXENOz8J0Common Applications of ISO 8295 Testing

Industries using ISO 8295 COF data include:

- Food packaging: To optimize vertical and horizontal bagging systems

- Förpackningar för medicintekniska produkter: Ensuring sterile barrier packaging doesn’t stick or slide excessively

- Adhesive labels and tapes: Where release liner performance depends on friction characteristics

- Läkemedelsförpackningar: To maintain dimensional stability during blister packing

Understanding the COF also supports efterlevnad av regelverk, particularly where machinability and safety are concerned.

Choosing the right Coefficient Of Friction Tester

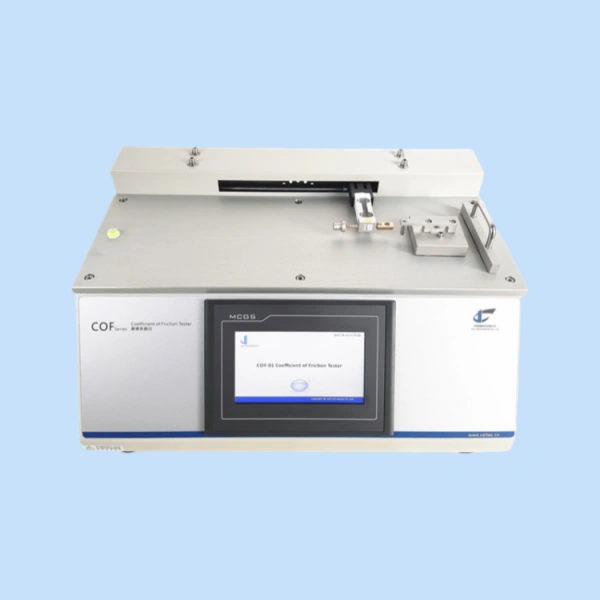

To implement ISO 8295 in your lab, you need precise instrumentation that meets the standard’s requirements. The Cellinstrument Friktionskoefficienttestare is designed to:

- Accurately measure both static and dynamic COF

- Support friction testing of films against film, metal, or other surfaces

- Offer programmable test speeds and load configurations

- Provide digital outputs for easy data analysis and quality documentation

Whether you’re testing polyethylene film, BOPP, PET, or multilayer laminates, Cell Instruments’ testers ensure upprepningsbar, standardkompatibel, och high-precision COF measurement.

Kontakta oss Få lösning för testning av friktionskoefficient

Oavsett om du är i plast-, pappers-, förpacknings- eller medicinteknisk tillverkning, understanding and applying ISO 8295 gives you a competitive edge. With the right testare av friktionskoefficient som COF-01 Med Cell Instruments blir din verksamhet mer konsekvent, effektiv och efterlevnadsinriktad.

Kontakt Cellinstrument idag för att få veta hur våra lösningar kan förbättra din testkapacitet och produktkvalitet.

Vanliga frågor

1. What is ISO 8295 used for?ISO 8295 is used to measure the static and dynamic coefficients of friction of plastic films and sheeting, helping assess slip properties for processing and handling.

2. Why is COF important in packaging films?The coefficient of friction impacts machinability, stacking, sealing, and transport of films. Proper COF ensures smooth processing and prevents issues like sticking or misfeeding.

3. How do additives affect COF?Slip additives migrate to the surface over time and reduce friction. However, their effect can vary with age, humidity, and formulation, making COF testing crucial.

4. Can ISO 8295 be used for non-film materials?It is primarily designed for plastic films up to 0.5 mm, but with adjustments, it can also test films against metal, paper, or other substrates.