Testeur de volume de CO2 : Garantir une carbonatation précise des boissons avec l'ASTM F1115

Testeur de volume de CO2 : Assurer une bonne carbonatation des boissons

Maintien de la bonne la teneur en dioxyde de carbone (CO2) est essentiel pour préserver le goût, l'effervescence et la qualité globale des boissons gazeuses. Que vous produisiez des boissons gazeuses, de l'eau pétillante ou de la bière, il est essentiel de mesurer et de contrôler les niveaux de CO2. A Testeur de teneur en dioxyde de carbone est l'instrument clé pour évaluer avec précision les niveaux de carbonatation dans les contenants de boissons. Cet outil permet de s'assurer que les boissons répondent aux normes souhaitées en matière d'effervescence et de stabilité à l'étalage.

Dans cet article, nous examinerons l'importance de la mesure des niveaux de CO2, la façon dont le système d'échange de quotas d'émission de CO2 est utilisé. Testeur de teneur en dioxyde de carbone fonctionne, et comment ASTM F1115 guide l'analyse précise de la teneur en CO2 des boissons gazeuses.

ASTM F1115 : La norme pour les tests de teneur en CO2

ASTM F1115 est une norme cruciale qui guide les tests de perte de CO2 et les niveaux de carbonatation dans les contenants de boissons. La méthode d'essai décrite par l'ASTM permet aux fabricants de boissons de déterminer dans quelle mesure leurs récipients conservent la carbonatation, ce qui est essentiel pour la qualité du produit. ASTM F1115 prévoit deux procédures principales - la procédure A et la procédure B - pour mesurer la teneur en CO2 des boissons gazeuses :

Procédure A est plus précise et est généralement utilisée en laboratoire pour développer des modèles d'emballage et évaluer leur capacité à conserver la carbonatation dans le temps. Elle nécessite un équipement spécialisé tel que des micro-capteurs de pression et des thermocouples pour mesurer la pression interne et la température du récipient scellé. Cette méthode garantit un degré élevé de précision pour la recherche et le développement.

Procédure B est plus simple et plus couramment utilisé dans les environnements de production et de contrôle de la qualité. Il utilise des ensembles de pression manuels ou des analyseurs de CO2 automatisés, ce qui le rend idéal pour les tests de routine des niveaux de CO2 dans les lignes de production.

Les deux procédures se concentrent sur la mesure des niveaux de carbonatation dans les boissons et sur l'évaluation de l'efficacité des matériaux d'emballage à maintenir ces niveaux pendant le stockage et la distribution. ASTM F1115 fournit le cadre permettant de garantir que les boissons répondent aux normes de qualité et de sécurité.

Pourquoi un testeur de volume de CO2 est-il indispensable ?

Le testeur de volume de co2 est conçu pour mesurer la quantité de CO2 dissous dans une boisson, ce qui a un impact direct sur le goût, la texture et la qualité de la boisson. Le testeur aide les fabricants à vérifier que leurs niveaux de carbonatation se situent dans la plage spécifiée, ce qui permet d'éviter des problèmes tels que :

Boissons plates: Lorsque les niveaux de CO2 sont trop bas, la boisson devient plate et perd l'effervescence souhaitée.

Pression excessive: La sur-carbonatation peut entraîner une surpression des conteneurs, ce qui augmente le risque de fuites, d'explosions de bouteilles ou de compromission des joints d'étanchéité.

UN Testeur de teneur en dioxyde de carbone permet de détecter rapidement ces problèmes et de s'assurer que les produits répondent aux normes de qualité et de sécurité attendues. En contrôlant la teneur en CO2, les fabricants peuvent maintenir la cohérence de leurs produits et améliorer la satisfaction de leurs clients.

Fonctionnement du testeur de teneur en dioxyde de carbone

Le testeur de volume de co2 fonctionne en mesurant la pression interne des contenants de boissons scellés. Cette pression est directement liée au volume de CO2 dissous dans le liquide. Le testeur calcule le niveau de carbonatation sur la base des relevés de pression, ce qui permet aux fabricants d'évaluer la précision de leur processus de carbonatation.

En règle générale, le processus consiste à sceller une bouteille ou une canette avec la boisson à l'intérieur, puis à mesurer la pression interne à l'aide de systèmes manuels ou automatisés. ASTM F1115 fournit des procédures détaillées sur la façon de mettre en place l'environnement de test, d'étalonner les instruments et d'interpréter les résultats.

Pour Procédure ADes outils de haute précision sont nécessaires pour mesurer la température et la pression, tandis que les outils de mesure de la température et de la pression sont nécessaires pour mesurer la température et la pression. Procédure B permet d'effectuer des tests plus simples à l'aide d'analyseurs de CO2 manuels ou automatiques. Les deux méthodes fournissent des données cruciales qui aident les fabricants à maintenir des niveaux de carbonatation optimaux tout au long du cycle de production.

Avantages d'une mesure précise du CO2 dans la production de boissons

L'utilisation régulière d'un Testeur de teneur en dioxyde de carbone offre de nombreux avantages aux fabricants de boissons :

Contrôle de la qualité: Le contrôle des niveaux de CO2 garantit que les boissons répondent aux normes de carbonatation souhaitées, en évitant les problèmes tels que l'aplatissement ou la sur-carbonatation.

Cohérence: Des tests de CO2 précis garantissent que chaque lot de boisson a une carbonatation constante, ce qui assure une expérience uniforme au consommateur.

Conformité réglementaire: Suivant ASTM F1115 garantit que les fabricants respectent les normes industrielles en matière de niveaux de carbonatation, ce qui permet d'éviter d'éventuels problèmes réglementaires.

Économies de coûts: En détectant rapidement les pertes de CO2, les fabricants peuvent réduire les déchets, améliorer l'efficacité et prévenir les défauts des produits qui peuvent entraîner des retours ou des pertes.

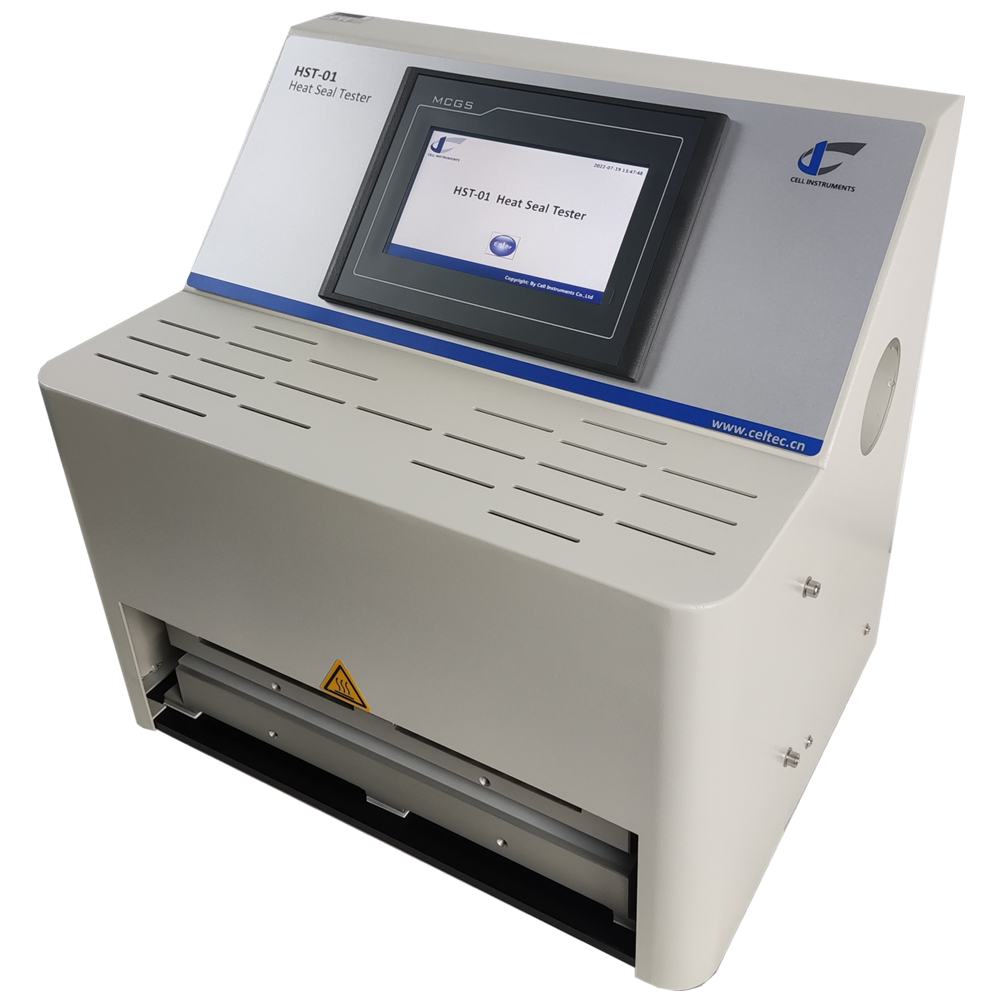

Équipement recommandé : L'appareil de mesure du CO2 CLRT-01 Volume Testeur

Pour les fabricants qui cherchent à améliorer leur processus de test de carbonatation, le CLRT-01 Testeur de volume de CO2 de Cell Instruments est un excellent choix. Le CLRT-01 est conçu pour offrir des mesures de CO2 précises et exactes, garantissant que les boissons répondent aux normes de carbonatation requises. Il est conçu pour prendre en charge à la fois ASTM F1115 Procédure A et Procédure B, ce qui le rend polyvalent pour les environnements de R&D et de production. Grâce à son interface conviviale et à ses performances fiables, le CLRT-01 est l'outil idéal pour maintenir des niveaux de carbonatation de haute qualité dans vos boissons.

Conclusion

Le Testeur de teneur en dioxyde de carbone est un outil essentiel dans la production de boissons gazeuses, car il garantit que les niveaux de CO2 sont mesurés et maintenus avec précision. En se conformant aux ASTM F1115 les fabricants peuvent garantir que leurs boissons répondent aux exigences de qualité et de sécurité. Des tests réguliers effectués à l'aide d'un Testeur de teneur en CO2 garantit que les boissons conservent l'effervescence souhaitée, ce qui améliore le goût, la consistance du produit et la durée de conservation.

Investir dans un équipement de test fiable comme le CLRT-01 Testeur de teneur en CO2 aide les fabricants à rationaliser leurs processus de production et à fournir des produits de haute qualité aux consommateurs. Que vous travailliez dans le domaine de la recherche et du développement ou du contrôle de la qualité, la précision des tests de CO2 est cruciale pour maintenir l'intégrité de vos boissons gazeuses.