Penguji Kompresi Kotak: Menguji Kekuatan Kemasan dengan ASTM D642 & Kekuatan Susun

Penguji Kompresi Kotak: Memastikan Kekuatan dan Daya Tahan Kemasan

Dalam industri pengemasan, memastikan kekuatan kemasan sangat penting untuk melindungi produk selama pengangkutan. The penguji kompresi kotak memainkan peran penting dalam proses ini, yang memungkinkan produsen menguji bahan kemasan untuk mengetahui kemampuannya dalam menahan gaya tekan selama pengiriman. Baik itu karton bergelombang, plastik, atau bahan lainnya, penguji kompresi kotak membantu mengukur kekuatan susun dan ketahanan tekan kemasan secara keseluruhan, memastikan bahwa kemasan tersebut dapat bertahan dalam perjalanan.

Artikel ini akan memperkenalkan penguji kompresi kotak, jelajahi metode pengujian, dan soroti standar yang relevan seperti ASTM D642 untuk menunjukkan bagaimana pengujian ini dapat meningkatkan kualitas dan kinerja kemasan.

ASTM D642: Standar untuk Pengujian Kompresi Kotak

Itu ASTM D642 Standar ini memberikan pedoman untuk melakukan tes kompresi kotak untuk mengevaluasi ketahanan tekan kontainer pengiriman, standar ini memastikan bahwa produsen menggunakan metode yang konsisten dan dapat diandalkan untuk menguji kemasan di bawah tekanan. penguji kompresi kotak dirancang untuk memberikan gaya terkontrol pada kemasan untuk mensimulasikan gaya eksternal yang akan dihadapi selama penyimpanan dan transportasi.

ASTM D642 mencakup berbagai orientasi tekanan, termasuk dari atas ke bawah, ujung ke ujung, dan sudut ke sudut, yang memungkinkan produsen menilai bagaimana bahan kemasan akan bereaksi dalam kondisi dunia nyata yang berbeda.Dengan mematuhi ASTM D642, produsen dapat memastikan kemasan mereka memenuhi standar kekuatan dan daya tahan yang diperlukan untuk penanganan dan pengiriman.

Uji Kompresi Kemasan: Mengapa Ini Penting

A uji kompresi kemasan dirancang untuk mengukur kemampuan kemasan dalam menahan gaya tekan yang dialami selama pengiriman. Kemasan sering kali menghadapi gaya-gaya ini saat ditumpuk dalam palet atau mengalami tekanan eksternal selama pengangkutan. The uji kompresi kemasan membantu mengidentifikasi apakah bahan kemasan dapat menahan tekanan ini tanpa gagal.

Contohnya, kotak pengiriman yang terbuat dari karton bergelombang harus tahan terhadap gaya vertikal dan lateral. The penguji kompresi kotak mensimulasikan kondisi ini dengan memberikan gaya pada kemasan dan mengamati bagaimana reaksinya. Tes ini mengukur kekuatan susun dari kemasan-kemampuannya untuk menahan beban saat ditumpuk-dan memastikan bahwa kemasan tidak akan runtuh atau rusak selama penyimpanan atau pengangkutan.

Dengan melakukan uji kompresi kemasan, produsen dapat mengidentifikasi titik-titik lemah dalam kemasan mereka dan melakukan penyesuaian yang diperlukan sebelum pengiriman, sehingga mengurangi risiko kerusakan produk dan meningkatkan kepuasan pelanggan.

Pengujian ini sangat penting bagi industri yang mengandalkan kemasan untuk melindungi produk mereka selama pengiriman. Jika kemasan gagal menahan kompresi, hal ini dapat menyebabkan kerusakan produk, peningkatan biaya pengiriman, dan ketidakpuasan pelanggan. Dengan melakukan a uji kompresi kemasan, produsen dapat memastikan bahwa kemasan mereka dapat bertahan dalam tantangan pengangkutan, melindungi produk dari kerusakan sekaligus meningkatkan efisiensi rantai pasokan.

Kekuatan Susun: Menilai Kemampuan Menahan Beban

Kekuatan susun mengacu pada kemampuan kemasan untuk menopang beban tambahan dari kotak yang ditumpuk di atasnya. The penguji kompresi kotak mengevaluasi kekuatan ini dengan mensimulasikan kekuatan yang dialami kotak bertumpuk selama penyimpanan dan transit. Hal ini terutama penting untuk produk yang dikirim dalam jumlah besar atau disimpan dalam palet bertumpuk.

Kotak yang kurang memadai kekuatan susun dapat roboh karena berat kotak lainnya, sehingga dapat menyebabkan kerusakan pada kemasan dan produk di dalamnya. Kotak yang rusak penguji kompresi kotak menyediakan data berharga tentang kekuatan susun bahan pengemasan, memastikan bahwa bahan tersebut dapat menahan tekanan barang yang ditumpuk tanpa gagal.

Cara Kerja Penguji Kompresi Kotak

Itu penguji kompresi kotak menggunakan proses yang sederhana namun efektif untuk menilai kekuatan kemasan. Kemasan sampel ditempatkan di antara dua pelat datar-satu di bagian atas dan satu di bagian bawah. Mesin secara bertahap memberikan beban tekan, mensimulasikan tekanan yang akan dialami kemasan selama pengangkutan atau penyimpanan.

Saat tekanan meningkat, maka penguji kompresi kotak mengukur gaya yang diperlukan untuk menyebabkan kemasan gagal atau berubah bentuk. Hasilnya membantu produsen menentukan kekuatan susun dan ketahanan tekan material. Informasi ini kemudian dapat digunakan untuk membuat penyesuaian yang diperlukan untuk meningkatkan desain kemasan, memastikan bahwa kemasan tersebut bekerja dengan baik dalam kondisi dunia nyata.

Meningkatkan Kemasan Anda dengan Peralatan Pengujian yang Tepat

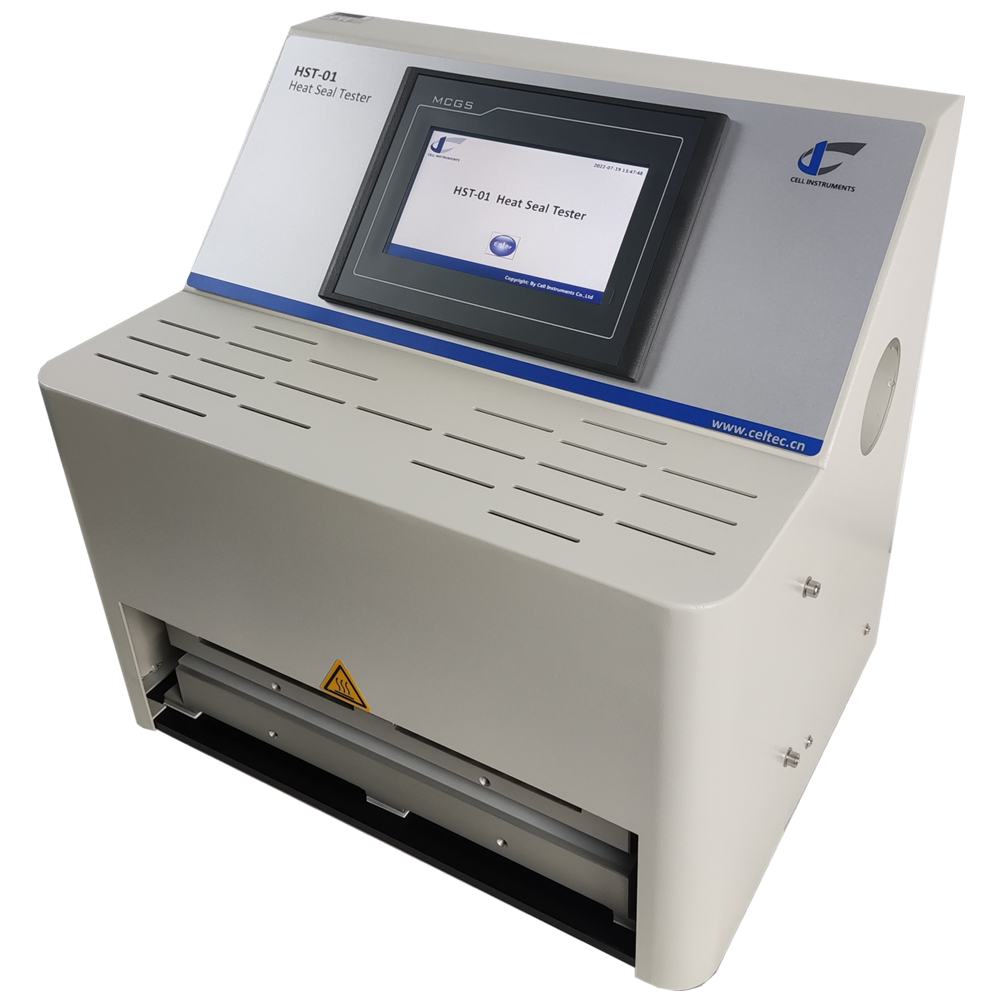

Untuk memastikan daya tahan kemasan, produsen memerlukan peralatan pengujian yang andal. Peralatan pengujian penguji kompresi kotak sangat penting untuk mengevaluasi kekuatan susun, ketahanan kompresi, dan kinerja bahan kemasan secara keseluruhan. Perusahaan seperti Cell Instruments menawarkan solusi pengujian tingkat lanjut, seperti Penguji Kompresi Kotak BCT-01, dirancang untuk memenuhi persyaratan ASTM D642. Alat ini memberikan hasil yang akurat dan dapat diulang, sehingga membantu perusahaan mengidentifikasi potensi kelemahan pada kemasan mereka sebelum menjadi masalah.

Dengan menggunakan penguji kompresi kotak seperti BCT-01, produsen dapat memperoleh pemahaman yang lebih dalam tentang bahan kemasan mereka, mengoptimalkan desain mereka, dan meningkatkan keamanan produk selama pengangkutan.

Kesimpulan

Itu penguji kompresi kotak adalah alat yang sangat diperlukan untuk memastikan kekuatan dan keandalan bahan kemasan. Dengan melakukan uji kompresi kemasan dan menilai kekuatan susun, produsen dapat memastikan bahwa kemasan mereka akan bertahan di bawah tekanan transportasi. Mematuhi ASTM D642 standar dan menggunakan alat seperti Penguji Kompresi Kotak BCT-01 membantu menjamin bahwa kemasan memenuhi persyaratan kekuatan yang diperlukan untuk melindungi produk dari kerusakan.

Untuk produsen yang ingin meningkatkan kualitas dan keandalan kemasan mereka, berinvestasi dalam penguji kompresi kotak adalah langkah yang cerdas. Dengan menguji kemasan untuk kekuatan susun Dan ketahanan kompresi, produsen dapat menghindari kesalahan yang merugikan, meningkatkan perlindungan produk, dan meningkatkan kepuasan pelanggan.