Penguji Karbon Dioksida: Memastikan Kesegaran dan Kualitas Minuman

Itu penguji karbon dioksida memainkan peran penting dalam industri minuman, memastikan bahwa minuman berkarbonasi, seperti soda, mempertahankan desis dan kualitasnya. Kadar CO₂ dalam minuman terkait langsung dengan rasa produk, masa simpan, dan pengalaman konsumen secara keseluruhan. Dengan mengukur kadar karbon dioksida secara akurat, produsen dapat menjamin bahwa produk mereka memenuhi standar industri dan ekspektasi konsumen.

ASTM F1115: Standar untuk Pengujian Karbon Dioksida dalam Minuman

Itu ASTM F1115 Standar ini menguraikan metode untuk menentukan hilangnya karbon dioksida dalam wadah minuman. Standar ini digunakan secara luas di industri minuman untuk menilai seberapa baik wadah mempertahankan karbonasi dari waktu ke waktu. Menurut standar ini, kadar karbon dioksida dalam botol diukur secara berkala untuk menghitung kehilangan karbonasi dan laju perpindahannya, sehingga kesegaran minuman dapat dipertahankan selama masa simpannya.

Pengujian ini sangat penting bagi industri pengemasan minuman karena mengevaluasi bagaimana desain dan bahan kemasan yang berbeda memengaruhi retensi CO₂. Hal ini penting untuk memastikan bahwa minuman tetap segar, beraroma, dan menarik bagi konsumen.

Bagaimana Cara Kerja Penguji Karbon Dioksida?

A penguji karbon dioksida bekerja dengan mengukur kandungan CO₂ dalam wadah minuman sebelum dan sesudah terpapar kondisi lingkungan tertentu. Proses pengujiannya sederhana namun membutuhkan ketelitian. Ada dua prosedur utama dalam ASTM F1115 untuk melakukan pengujian CO₂: Prosedur A dan Prosedur B.

Prosedur A: Pengukuran CO₂ Presisi Tinggi

Prosedur A biasanya digunakan dalam pengaturan laboratorium yang memerlukan presisi tinggi. Prosedur ini menggunakan peralatan pemantauan tekanan dan suhu yang sensitif, termasuk transduser tekanan mikro dan termokopel, untuk mengukur tingkat karbonasi secara akurat. Botol uji disegel, dan tekanan CO₂ dipantau dari waktu ke waktu. Pengujian ini ideal untuk mengevaluasi desain wadah minuman baru atau memperbaiki desain yang sudah ada.

Prosedur B: Kontrol Kualitas yang Lebih Sederhana untuk Operasi Pengisian

Prosedur B lebih umum digunakan dalam operasi pengisian sebagai alat kontrol kualitas. Metode ini melibatkan peralatan yang lebih sederhana, seperti penganalisis CO₂ otomatis atau rakitan tekanan manual, untuk memantau tingkat karbonasi dalam wadah minuman. Metode ini banyak digunakan untuk mempertahankan tekanan pengisian CO₂ yang diinginkan selama produksi, memastikan bahwa produk memenuhi standar kualitasnya sebelum sampai ke tangan konsumen.

Pentingnya Mengukur CO₂ dalam Minuman

Mempertahankan jumlah yang tepat dari karbon dioksida dalam minuman sangat penting karena beberapa alasan:

- Rasa dan Kesegaran: Kesegaran minuman berkarbonasi secara langsung dipengaruhi oleh jumlah CO₂ dalam minuman. Kehilangan CO₂ dapat menyebabkan minuman menjadi datar dan kurang nikmat.

- Umur simpan: Kemampuan wadah untuk mempertahankan karbonasi memengaruhi umur simpan minuman. Kehilangan CO₂ dapat memengaruhi rasa dan kesegaran produk yang dirasakan, sehingga konsumen tidak puas dan berpotensi mengembalikan produk.

- Kepatuhan terhadap Peraturan: Kepatuhan terhadap standar seperti ASTM F1115 memastikan bahwa produsen minuman mematuhi peraturan industri dan menjaga konsistensi produk di seluruh batch.

Efisiensi Biaya: Dengan mengukur retensi CO₂, produsen dapat menghindari biaya pengemasan yang cacat yang menyebabkan hilangnya karbonasi dan potensi pembusukan produk.

Kandungan Karbondioksida dalam Cola

Khas cola mengandung sekitar 2,5 hingga 3,0 volume CO₂. Tingkat ini memastikan rasa bersesis yang seimbang yang memberikan rasa yang memuaskan di mulut. Mengukur dan mempertahankan level ini sangat penting, karena pengurangan sedikit saja pada level CO₂ dapat secara signifikan memengaruhi rasa dan kualitas minuman secara keseluruhan.

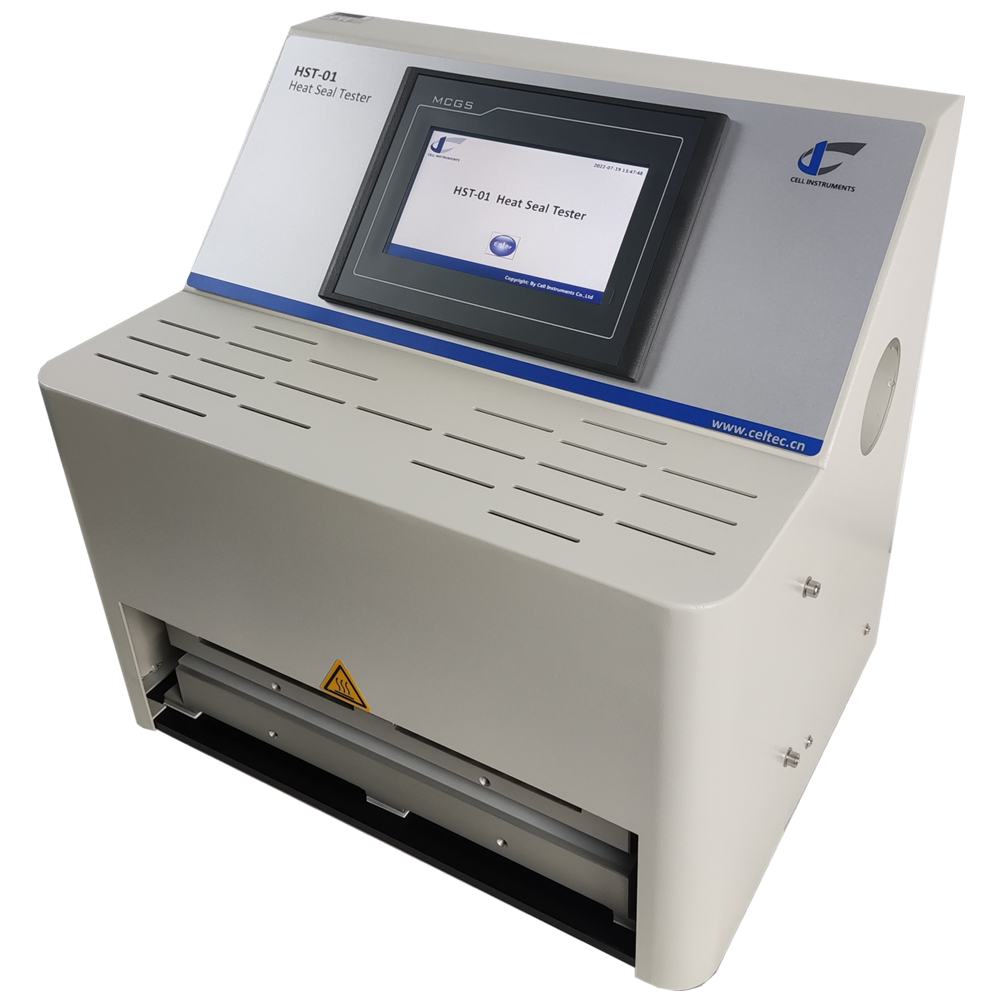

Mengapa Memilih Cell Instruments untuk Kebutuhan Pengujian Karbon Dioksida Anda?

Pada Instrumen Sel, kami mengkhususkan diri dalam menyediakan presisi tinggi penguji karbon dioksida dirancang untuk memenuhi persyaratan ketat ASTM F1115. Produk kami menawarkan kinerja yang andal baik di lingkungan laboratorium maupun produksi, memastikan bahwa minuman Anda mempertahankan tingkat karbonasi yang diinginkan selama masa simpannya.

Kita penguji karbon dioksida memiliki sistem otomatis yang menyederhanakan prosedur pengujian, mengurangi kesalahan manusia, dan meningkatkan efisiensi. Baik Anda memerlukan pengujian presisi tinggi untuk R&D atau solusi hemat biaya untuk kontrol kualitas rutin, kami memiliki alat yang tepat untuk memenuhi kebutuhan Anda. Keahlian kami dalam solusi pengujian yang disesuaikan memungkinkan kami untuk memenuhi kebutuhan spesifik produsen minuman, memastikan proses produksi Anda berjalan dengan lancar.

Kesimpulan

Itu penguji karbon dioksida adalah alat penting bagi produsen minuman yang ingin mempertahankan kualitas, kesegaran, dan rasa produk mereka. Dengan mengikuti ASTM F1115 standar, perusahaan dapat memastikan bahwa kemasan mereka dioptimalkan untuk retensi CO₂, sehingga memberikan produk yang menyegarkan secara konsisten kepada konsumen. Di Instrumen Sel, kami berkomitmen untuk mendukung industri minuman dengan instrumen pengujian canggih yang membantu Anda mempertahankan standar kualitas tinggi dan memenuhi kepatuhan terhadap peraturan dengan mudah.