Corrugated Box Compression Testing Machine for Stacking Strength and Carton Durability

Corrugated Box Compression Testing Machine Overview

A corrugated box compression testing machine plays a central role in evaluating how well cartons withstand real-world storage and distribution conditions. Manufacturers, quality control teams, and logistics operators rely on this instrument to measure stacking strength, carton durability, and packaging performance under controlled compressive loads. As product protection standards rise across food, medical, pharmaceutical, electronics, and e-commerce industries, reliable compression analysis becomes essential for reducing packaging failures and lowering logistics risks.

Corrugated boxes encounter constant static pressure during warehouse stacking and dynamic forces throughout transportation. Without accurate testing, deformation and collapse risks increase. By applying uniform and measurable compression, this machine helps users determine the maximum load a carton can resist before failure, providing crucial data for packaging design optimization and supply-chain safety.

ASTM D642 and Its Role in Compression Testing

ASTM D642 and Industry Requirements

The principles of ASTM D642 guide how compression loads should be applied to shipping containers, ensuring a standardized method for quantifying compressive resistance. This internationally recognized test approach evaluates cartons with or without contents and allows testing on faces, edges, or corners. Following this procedure improves test repeatability and ensures results align with packaging standards used by global manufacturers.

ASTM D642 emphasizes accurate platen alignment, proper sample conditioning, and consistent loading rates. These details influence stacking strength and carton durability, making the test method valuable for packaging engineers. The standard also highlights the importance of specimen centering and consistent deformation measurements, allowing users to compare various carton constructions or validate new packaging designs.

Why Stacking Strength Matters in Real Packaging Applications

Stacking strength directly affects warehouse safety and transport stability. Insufficient strength leads to carton collapse, product damage, and costly returns. A corrugated box compression testing machine helps determine:

- Maximum load a box can safely withstand

- Structural differences between single-wall, double-wall, and heavy-duty cartons

- Performance variations due to humidity, paper grade, or design changes

How interior packaging contributes to load sharing

By understanding these parameters, packaging engineers can design cartons that survive long-term storage and stacked pallet loads. This reduces waste, improves product protection, and ensures compliance with international packaging standards.

Key Features of a High-Quality Compression Testing Machine

A reliable corrugated box compression testing machine typically includes:

- Rigid, parallel platens for consistent compression

- High-precision load cells for accurate force measurement

- Adjustable crosshead speed to meet test standards

- Large testing space accommodating full-size cartons

- Real-time load–deformation curves

Stable servo or stepper drive systems for smooth operation

These features allow users to analyze not only peak compressive strength but also deformation behavior, revealing how the box gradually loses stability under pressure.

Enhancing Carton Durability Evaluation

Carton durability depends on board structure, packaging design, climate conditions, and transportation environment. A compression test simulates vertical loads comparable to stacked pallets or heavy cargo. Test results help:

- Predict carton lifespan under warehouse storage

- Identify weak structural points

- Improve board selection for export or long-distance shipping

- Support quality control and supplier benchmarking

Validate packaging changes before mass production

For industries with strict compliance requirements—such as medical device packaging, pharmaceuticals, food products, and consumer electronics—durable cartons help maintain product integrity and reduce regulatory risks.

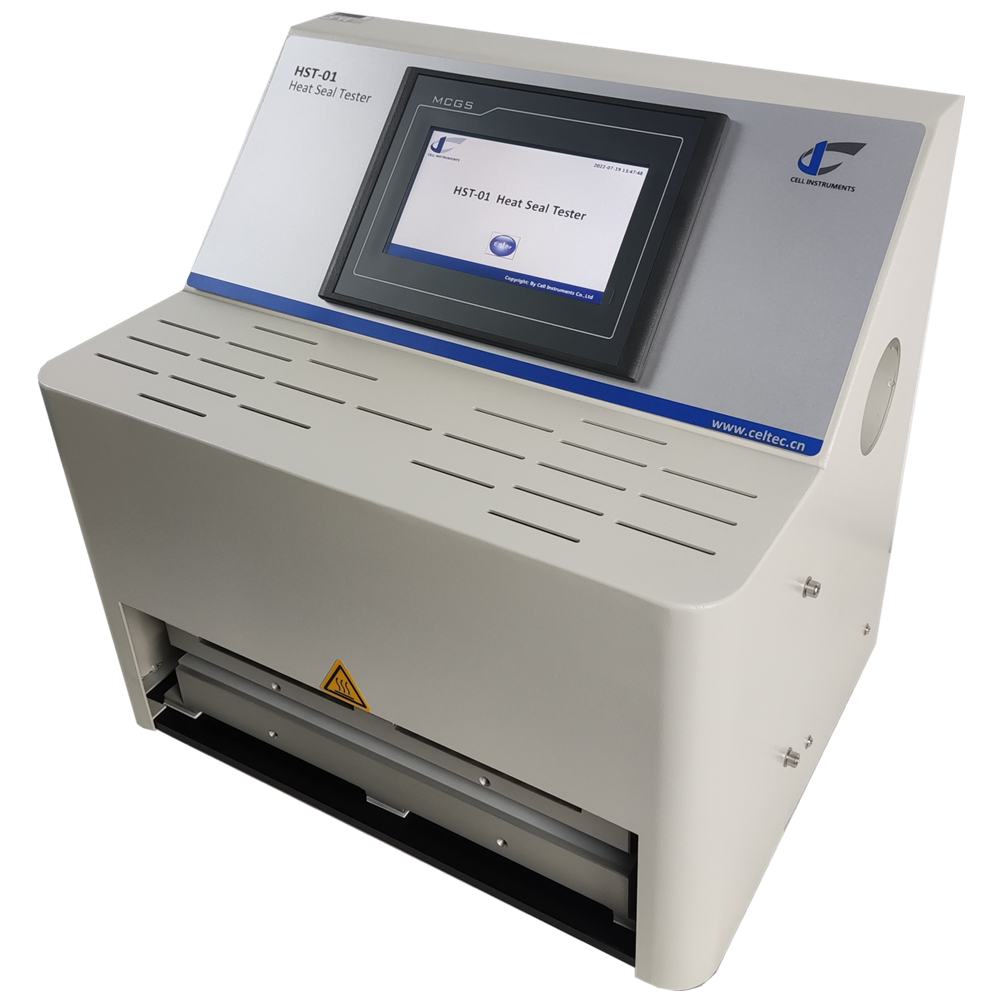

Cell Instruments Solutions for Corrugated Box Testing

Cell Instruments offers advanced and reliable solutions for carton compression analysis. Our box compression testers deliver stable force application, large testing capacities, and user-friendly software interfaces. Designed for professional quality laboratories, packaging manufacturers, and third-party inspection agencies, these instruments help users obtain precise data on stacking strength and carton durability.

We also provide customized platen sizes, extended load capacities, and automation upgrades to match specific testing needs. Whether customers evaluate domestic shipping cartons or heavy-duty export boxes, Cell Instruments supports complete packaging performance analysis with strong technical expertise.

Conclusion

A corrugated box compression testing machine is essential for ensuring packaging reliability across multiple industries. By following the guidelines of ASTM D642, users can accurately measure compressive resistance, optimize carton design, and improve stacking performance. With rising quality demands and tighter logistics standards, investing in reliable compression testing equipment—such as solutions from Cell Instruments—helps businesses maintain product safety and strengthen supply-chain efficiency.