Tiêu chuẩn ASTM F1306

Thử nghiệm thấm chậm của phim

Các vật liệu đóng gói linh hoạt như màng chắn và vật liệu ghép lớp được sử dụng rộng rãi trong các ngành công nghiệp như thực phẩm, thiết bị y tế và dược phẩm. Để đảm bảo an toàn sản phẩm và thời hạn sử dụng, việc đánh giá cách các vật liệu này phản ứng với áp lực đâm thủng là điều cần thiết. Tiêu chuẩn ASTM F1306 Cung cấp một phương pháp tiêu chuẩn để đánh giá khả năng chống lại sự xâm nhập chậm của một vật liệu bởi một đầu dò được đẩy. Thử nghiệm này định lượng Lực, năng lượng và độ sâu xuyên thấu Trong trường hợp hư hỏng, giúp các nhà sản xuất đánh giá xem màng nhựa có thể chịu được các vật thể có cạnh sắc nhọn trong quá trình xử lý, lưu trữ hoặc sử dụng hay không.

Yêu cầu báo giáHiểu về tiêu chuẩn ASTM F1306

Tiêu chuẩn ASTM F1306 có tiêu đề Phương pháp thử tiêu chuẩn để xác định khả năng chống thấm chậm của màng rào cản linh hoạt và vật liệu composite.Phương pháp này đánh giá khả năng chống đâm thủng của màng khi được tác động bởi một lực. Đầu dò được điều khiển di chuyển với tốc độ chậm và được kiểm soát.Các chỉ số chính bao gồm:

- Lực đỉnh Yêu cầu phải đâm thủng màng phim.

- Năng lượng để phá vỡ (Tổng công việc thực hiện trong quá trình chọc dò)

- Khoảng cách xuyên thấu của đầu dò khi hỏng hóc

Các thông số này cho biết mức độ chịu đựng của một bộ phim. Áp lực đâm xuyên cơ học có thể xảy ra trong quá trình xử lý, vận chuyển hoặc lưu trữ.

Tại sao thử nghiệm khả năng chống thấm lại quan trọng?

Màng bao bì bảo vệ các sản phẩm nhạy cảm khỏi chất gây ô nhiễm, khí và độ ẩmNếu sản phẩm có cạnh sắc nhọn hoặc lực tác động từ bên ngoài làm rách màng, chức năng rào cản có thể bị hỏng, dẫn đến:

- Mất tính toàn vẹn của sản phẩm

- Thời hạn sử dụng ngắn hơn

- Nguy cơ an toàn do ô nhiễm

- Tăng số lượng hàng trả lại hoặc thu hồi sản phẩm

Các Khả năng chống thủng của màng nhựa do đó đóng vai trò quan trọng trong việc đảm bảo chất lượng bao bì. Tiêu chuẩn ASTM F1306 quy định một tiêu chuẩn tham chiếuĐảm bảo kết quả nhất quán và có thể so sánh được giữa các phòng thí nghiệm.

Quy trình thử nghiệm khả năng chống xuyên thủng của màng phim

Các Thử nghiệm khả năng chống xuyên thủng của phim Được định nghĩa trong tiêu chuẩn ASTM F1306 bao gồm các bước sau:

- Chuẩn bị mẫuPhim được cắt thành các hình vuông có kích thước 76 mm × 76 mm.

- Cài đặt thiết bịMột máy kiểm tra đa năng được sử dụng cùng với đầu dò và giá đỡ mẫu phù hợp.

- Điều kiện thử nghiệmTốc độ đầu cắt được cố định ở 25 mm/phút. Việc thu thập dữ liệu phải ghi lại ít nhất 0,1 mm cho mỗi điểm xuyên qua.

- Tải mẫuPhim được kẹp chặt, và đầu dò được đặt ngay trên bề mặt.

- Thực hiện thử nghiệm đâm thủng: Đầu dò được đẩy vào phim cho đến khi xảy ra hiện tượng thủng.

- Thu thập dữ liệuLực đỉnh, năng lượng tổng và độ sâu xuyên thấu được ghi lại.

Bài kiểm tra áp dụng một Trạng thái ứng suất hai trục Trên phim, mô phỏng các tác động thực tế từ các sản phẩm có đầu nhọn hoặc sắc nhọn tác động lên bao bì.

Trong các ứng dụng đóng gói, màng phải chịu được không chỉ Lực kéo và lực rách nhưng cũng Nguy cơ thủngTiêu chuẩn ASTM F1306 giải quyết vấn đề này bằng cách tập trung vào Thử nghiệm đâm thủng với tốc độ chậm, mô phỏng các tác động dần dần như xếp chồng, rung động hoặc sự dịch chuyển của sản phẩm bên trong bao bì.

Các vật liệu khác nhau phản ứng khác nhau khi bị đâm thủng:

- Lớp màng dày hơn Thường có khả năng chống chịu tốt hơn nhưng có thể làm giảm độ linh hoạt.

- Vật liệu có mô đun đàn hồi cao Có thể bị rách đột ngột, trong khi các màng đàn hồi hơn có khả năng kéo dãn lớn hơn trước khi bị hỏng.

- Cấu trúc laminate Thường kết hợp sức mạnh và độ linh hoạt để đạt được hiệu suất cân bằng.

Bằng cách hiểu rõ các phản hồi này, các kỹ sư đóng gói có thể Tối ưu hóa thiết kế vật liệu Để đáp ứng cả yêu cầu về hiệu suất và chi phí.

Khả năng chống thủng của màng nhựa trong đóng gói

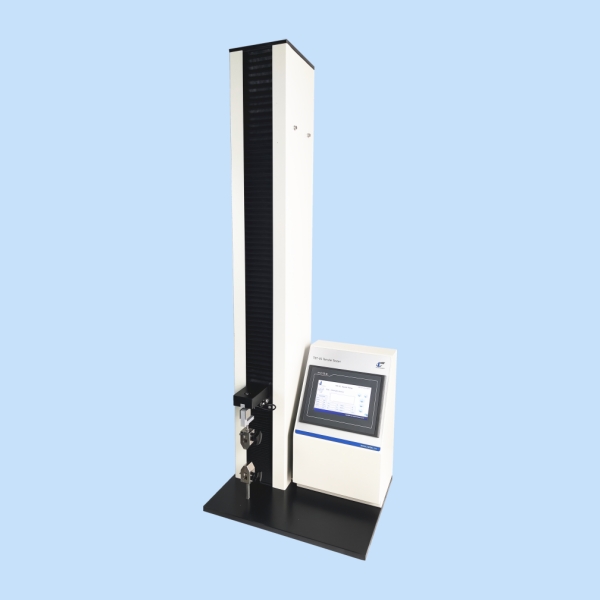

Thiết bị được khuyến nghị: Cell Instruments TST-01

Để thực hiện các thử nghiệm ASTM F1306 chính xác, một Máy thử nghiệm đa năng đáng tin cậy là điều cần thiết. The Cell Instruments TST-01 Máy thử kéo được khuyến nghị cao vì:

- Nó hỗ trợ thử nghiệm đâm thủng với các thiết bị chuyên dụng.

- Tốc độ và độ dịch chuyển của đầu trục có thể được điều khiển bằng độ chính xác cao.

- Nó ghi lại Lực, năng lượng và độ sâu xuyên thấu với phần mềm chuyên nghiệp.

- Nó Điều khiển PLC và màn hình cảm ứng HMI Làm cho thao tác trở nên trực quan.

- Nó có tính linh hoạt cao, đồng thời hỗ trợ các thử nghiệm về độ bền kéo, độ bền bóc tách, độ bền niêm phong và độ bền rách.

Bằng cách tích hợp TST-01 vào phòng thí nghiệm, các nhà sản xuất sẽ có được Giải pháp toàn diện Đánh giá hiệu suất của bao bì linh hoạt.

Liên hệ với chúng tôi để nhận giải pháp thử nghiệm theo tiêu chuẩn ASTM D1306.

Các Tiêu chuẩn ASTM F1306 phương pháp thử nghiệm đóng vai trò quan trọng trong việc đảm bảo độ bền và an toàn của màng rào cản linh hoạt và vật liệu composite. Thông qua quá trình kiểm soát Thử nghiệm khả năng chống xuyên thủng của phimCác chuyên gia đóng gói có thể định lượng được Khả năng chống thủng của màng nhựa và đưa ra quyết định có căn cứ về việc lựa chọn vật liệu và đảm bảo chất lượng. Với các thiết bị kiểm tra tiên tiến như là Cell Instruments TST-01Các doanh nghiệp có thể đạt được kết quả chính xác, có thể lặp lại và tuân thủ tiêu chuẩn, từ đó bảo vệ cả sản phẩm lẫn uy tín thương hiệu.