Hướng dẫn thử nghiệm độ bền mài mòn in ấn bằng phương pháp Sutherland Rub Test

Trong lĩnh vực bao bì in ấn, nhãn mác và phương tiện truyền thông in ấn thương mại, khả năng chống mài mòn là yếu tố quan trọng để duy trì chất lượng sản phẩm và thương hiệu. thử nghiệm cọ xát sutherland, được tiêu chuẩn hóa theo Tiêu chuẩn ASTMD5264, cung cấp một phương pháp đáng tin cậy để đánh giá độ bền của bề mặt in ấn trước tác động của ma sát hoặc trầy xước trong quá trình vận chuyển, lưu trữ hoặc xử lý. Bài viết này giải thích các nguyên tắc cơ bản của bài kiểm tra, nhấn mạnh các khuyến nghị quy trình thử nghiệm cọ xát sutherlandvà giới thiệu một giải pháp đáng tin cậy—Máy thử độ bền mài mòn mực Cell Instruments’ RT-01—để giúp các chuyên gia thực hiện các đánh giá chính xác và có thể lặp lại.

Hiểu rõ tầm quan trọng của bài kiểm tra Sutherland Rub

Các tài liệu in ấn thường gặp phải hiện tượng mài mòn bề mặt trong suốt vòng đời sản phẩm. Dù là trong quá trình vận chuyển, trưng bày trên kệ hay khi khách hàng sử dụng, ma sát có thể làm hỏng mực in, lớp phủ hoặc thông tin in ấn. thử nghiệm cọ xát sutherland cung cấp một phương pháp tiêu chuẩn để mô phỏng các điều kiện này và đánh giá:

- Các Khả năng chống mài mòn của mực in, lớp phủ hoặc vật liệu laminate

- So sánh hiệu suất mài mòn giữa các mẫu in

- Ảnh hưởng của các yếu tố môi trường như nhiệt độ hoặc độ ẩm đối với độ bền.

- Khả năng chống trầy xước của nhãn bao bì, hộp gấp và các vật liệu nền khác

Các Tiêu chuẩn ASTMD5264 Tiêu chuẩn quy định các bước cụ thể và cài đặt thiết bị để đảm bảo tính tái hiện và so sánh giữa các phòng thí nghiệm hoặc dây chuyền sản xuất khác nhau.

Quy trình thử nghiệm ma sát Sutherland theo tiêu chuẩn ASTM D5264

Việc triển khai đúng đắn của quy trình thử nghiệm cọ xát sutherland Điều này là cần thiết để thu thập dữ liệu hợp lệ và có thể áp dụng. Dưới đây là chi tiết về quy trình:

Thiết bị và Vật liệu

- Máy kiểm tra độ cọ xát Sutherland với trọng lượng có thể lựa chọn (2 pound hoặc 4 pound)

- Miếng đệm cao su (76 mm × 152 mm) với độ cứng Shore A là 15 ± 5

- Bảng tiếp nhận tiêu chuẩnKích thước 51 mm × 178 mm hoặc 51 mm × 102 mm

- Mẫu thử nghiệm (tốt nhất là 76 mm × 152 mm)

- Băng dính nhạy áp suất (nếu cần thiết)

- Cây chổi lông lạc đà chống tĩnh điện

- Môi trường được điều kiện hóa23 ± 1 °C và 50 ± 21% RH (theo tiêu chuẩn ASTM D4332)

Thực thi kiểm thử từng bước

- Điều kiệnĐảm bảo tất cả các vật liệu được bảo quản trong môi trường kiểm soát trong ít nhất 24 giờ.

- Sự chuẩn bị:

- Gắn mẫu thử vào miếng đệm cao su trên đế máy thử.

- Gắn thụ thể vào khối thụ thể bằng kẹp hoặc băng dính.

- Lựa chọn trọng lượng:

- Sử dụng khối 4 pound cho các ứng dụng có ma sát cao.

- Sử dụng khối 2 pound cho các tài liệu in ấn thông thường.

- Cài đặt đột quỵChọn trước số lần chu kỳ chà xát đôi (một chu kỳ là một chuyển động hoàn chỉnh qua lại).

- Kiểm tra:

- Đặt khối vào giá đỡ.

- Bật máy để bắt đầu các chu kỳ chà xát.

- Máy kiểm tra sẽ tự động dừng sau khi hoàn thành số lần đánh đã được cài đặt trước.

- Đánh giá:

- Kiểm tra bằng mắt thường mẫu thử nghiệm để phát hiện sự suy giảm (phai màu, mất mực).

- Phân tích bộ phận tiếp nhận mực in.

- So sánh với mẫu tham chiếu để định lượng khả năng chống mài mòn.

Các phương pháp tốt nhất để đảm bảo kết quả thử nghiệm ma sát đáng tin cậy

Để đảm bảo tính lặp lại và độ chính xác:

- Tránh kiểm tra quá mức: Số lần quét quá nhiều sẽ sinh nhiệt và làm sai lệch kết quả.

- Thay thế các miếng đệm cao su định kỳ; các miếng đệm bị mòn có thể làm giảm độ đồng đều.

- Giữ bề mặt sạch sẽ — sử dụng chổi chống tĩnh điện trước mỗi lần chạy.

- Giữ hướng của mẫu nhất quán, đặc biệt là theo hướng của máy.

- Tránh làm ô nhiễm mẫu bằng găng tay hoặc kẹp.

Ứng dụng và Lợi ích trong Lĩnh vực Đóng gói và In ấn

Các thử nghiệm cọ xát sutherland được áp dụng rộng rãi trong nhiều ngành công nghiệp:

- Dược phẩmĐảm bảo tính dễ đọc của nhãn liều lượng hoặc nhãn cảnh báo in trên sản phẩm.

- Thực phẩm và đồ uốngBảo đảm tính nhất quán về hình ảnh thương hiệu trên thùng carton và túi đựng.

- Mỹ phẩmKiểm tra độ mòn bề mặt của hộp gấp in hoặc vỏ bọc.

- Nhãn công nghiệpĐảm bảo độ bền trong điều kiện tiếp xúc với độ ẩm hoặc ma sát.

Nó cũng hỗ trợ các đội ngũ nghiên cứu và phát triển (R&D) trong Công thức mực, Lựa chọn chất nền, Và Đánh giá chất lượng Để đạt được hiệu suất đóng gói cạnh tranh.

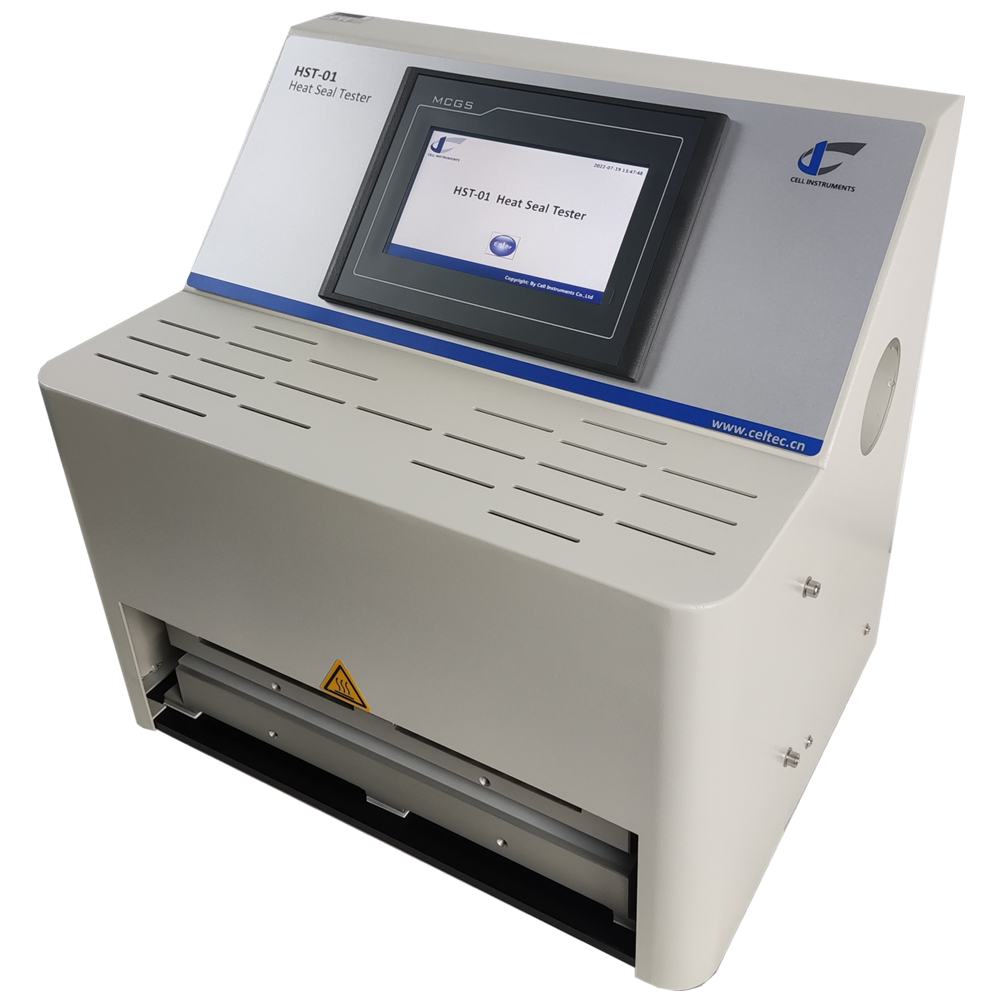

Tại sao nên chọn máy thử độ bền mài mòn mực RT-01 của Cell Instruments?

Các RT-01 từ Công ty TNHH Cell Instruments Được thiết kế đặc biệt để thử nghiệm khả năng chống mài mòn chính xác theo tiêu chuẩn ASTM D5264. Các tính năng chính bao gồm:

- Cài đặt hành trình thử nghiệm có thể điều chỉnh Để đảm bảo tính linh hoạt trên các loại sản phẩm

- Hỗ trợ cho cả khối trọng lượng 2 pound và 4 pound., lý tưởng cho nhiều điều kiện khác nhau

- Cơ chế truyền động bằng động cơ ổn định cho chuyển động đều đặn qua lại

- Hệ thống gắn mẫu dễ dàng Để giảm thiểu sai sót trong quá trình xử lý.

- Chất lượng gia công chắc chắnĐảm bảo tính nhất quán của các bài kiểm tra trong dài hạn.

Các chuyên gia trong lĩnh vực đóng gói, kiểm soát chất lượng và phát triển sản phẩm lựa chọn RT-01 vì hiệu suất cao, tính dễ sử dụng và khả năng tương thích với các tiêu chuẩn quốc tế.

Phần kết luận

Các thử nghiệm cọ xát sutherland là yếu tố không thể thiếu để đảm bảo độ bền và chất lượng của bao bì và nhãn mác in ấn. Tuân thủ đúng quy trình thử nghiệm cọ xát sutherland, như được định nghĩa bởi Tiêu chuẩn ASTMD5264, giúp các chuyên gia kiểm soát chất lượng phát hiện sớm các vấn đề tiềm ẩn về trầy xước và giảm thiểu rủi ro. Với Máy kiểm tra độ mài mòn mực RT-01 từ Dụng cụ tế bàoCác phòng thí nghiệm và cơ sở sản xuất có thể thực hiện các thử nghiệm tiêu chuẩn hóa, có thể lặp lại, giúp đưa ra các quyết định tự tin trong phát triển vật liệu và đảm bảo chất lượng.