Introduction to Packaging Pressure Testing

In industries such as medical devices, pharmaceuticals, food, and consumer goods, packaging quality is a critical factor. One of the most widely used methods to assess package strength is the packaging pressure testing bursting strength tester. This instrument evaluates a package’s resistance to internal pressurization and helps manufacturers prevent product failures during sterilization, shipping, or storage.

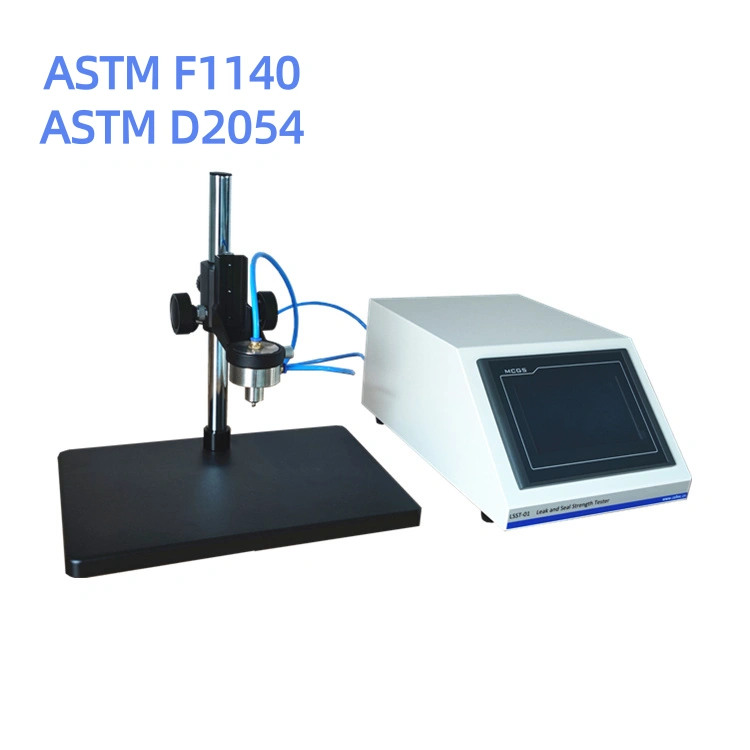

Standardit kuten ASTM F1140 ja ASTM F2054 provide structured methods to perform burst and creep tests, ensuring that test results are accurate, repeatable, and recognized worldwide.

Why Bursting Strength Testing Matters

Packages face stress from sterilization, transportation, and handling. If seals or materials are weak, failures such as leaks or ruptures can occur. By using a bursting strength tester, manufacturers can:

- Detect weak seals before products reach the market.

- Maintain compliance with ASTM F1140 ja ASTM F2054.

- Guarantee sterility and product protection.

- Improve packaging consistency across production batches.

ASTM F1140 Test Methods Explained

ASTM F1140 outlines internal pressurization failure resistance testing for unrestrained packages. There are three approaches:

- Burst Test (Method A): The package is pressurized until it ruptures. The maximum pressure before failure is recorded.

- Creep Test (Method B1): The package is pressurized to a set level and held for a specified duration, typically 15–30 seconds. Results are pass/fail.

- Creep to Failure (Method B2): Similar to the creep test, but pressure is held until the package eventually fails. The time until failure is measured.

These methods simulate real-world conditions such as sterilization cycles and altitude changes during transport.

ASTM F2054 Seal Testing with Restraining Plates

While ASTM F1140 deals with unrestrained packages, ASTM F2054 focuses on flexible package seals using internal air pressurization with restraining plates. Key points include:

- The package is placed between rigid plates to limit expansion.

- Pressurization continues until the seal area ruptures.

- The method indicates minimum burst strength, essential for ensuring seal reliability.

ASTM F2054 is particularly valuable for medical device pouches and pharmaceutical blister packs, where seal integrity is vital for sterility.

Equipment Requirements for Reliable Testing

Korkealaatuinen packaging pressure testing bursting strength tester must include:

- Tarkka pressure measurement sensors.

- A regulated air supply capable of steady or increasing pressurization.

- Configurations for open and closed package tests.

- Options for restraining plate fixtures (ASTM F2054).

Cell Instruments provides solutions such as the Cell Instruments Bursting Strength Tester (Model XXX), designed to comply with ASTM F1140 and ASTM F2054. With precision sensors and flexible testing configurations, it ensures consistent and valid results for packaging laboratories and quality control departments.

Sovellukset eri toimialoilla

Bursting strength testing is widely applied across various industries to ensure packaging integrity and product safety:

- Medical device packaging: This includes sterile pouches, syringes, blister packs, and other critical healthcare products. Bursting strength testing ensures that sterilized items remain uncontaminated during storage and transport, maintaining strict regulatory compliance.

- Pharmaceutical packaging: Foil-sealed bags, sachets, and unit-dose packs are tested to verify seal integrity and material strength. These tests help prevent leakage, preserve drug potency, and support adherence to industry standards such as ASTM F1140 and ASTM F2054.

- Food and beverage packaging: Vacuum-sealed bags, flexible pouches, and ready-to-eat meal packages are evaluated to ensure they withstand internal and external pressure during distribution, handling, and storage. Reliable packaging protects freshness, prevents spoilage, and reduces product returns.

- Consumer goods: Items such as daily chemicals, personal care products, and electronics often rely on flexible or protective packaging. Bursting strength testing identifies weak points in materials or seals, reducing the risk of leaks, breakage, or compromised product safety.

By applying bursting strength testing across these sectors, manufacturers can ensure product integrity, regulatory compliance, and consumer confidence, while optimizing packaging design for durability and cost-effectiveness.

Best Practices for Accurate Testing

To achieve reliable and reproducible results a:lla packaging pressure testing bursting strength tester, several best practices should be followed:

- Condition packages according to ASTM E171 before testing. Proper conditioning ensures that environmental factors such as temperature and humidity do not bias the test results, making the data more representative of real-world conditions.

- Maintain consistent parameters across samples. Variables like pressurization rate, seal configuration, and material type should remain uniform to enable accurate comparisons and prevent deviations caused by inconsistent setups.

- Record detailed preparation and failure observations. Documenting whether a failure occurred due to material rupture or seal separation is critical for diagnosing weaknesses and improving packaging design. This data not only supports compliance with ASTM F1140 and ASTM F2054 but also helps identify process improvements.

- Test both in-process and final packaged products. Evaluating samples during production allows early detection of quality issues, while testing fully packaged products validates the integrity and performance of the final packaging throughout its lifecycle.

- Incorporate both burst and creep testing methods. Burst tests measure maximum pressure resistance, while creep tests evaluate long-term seal stability under constant pressure. Using both approaches provides a more complete assessment of package performance.

By applying these practices, manufacturers can generate meaningful, actionable data that strengthens quality assurance programs and supports compliance with international standards.

Johtopäätös

The packaging pressure testing bursting strength tester is more than a laboratory instrument—it is a key tool for packaging quality assurance. Following ASTM F1140 ja ASTM F2054 procedures, manufacturers can accurately assess how packages respond to internal pressure, ensuring seals, materials, and designs meet the highest standards. Standardized methods provide reliable, comparable results, reducing the risk of recalls, contamination, or compromised sterility.

In modern production, where packaging impacts product safety, compliance, and consumer trust, the tester helps quality control teams identify weaknesses early, optimize materials, and maintain consistent integrity. This is crucial for industries such as medical devices, pharmaceuticals, and food, where failures can have serious consequences.

For companies seeking precise, efficient, and standards-compliant solutions... Cell Instruments Bursting Strength Tester delivers. With high-accuracy sensors, flexible configurations for open and closed packages, and compatibility with restraining plate methods, it ensures repeatable results and streamlined quality assurance processes. Integrating this tester helps businesses improve efficiency, ensure compliance, and protect their brand reputation—guaranteeing that products reach customers safely and reliably.