ISO 15359

Berzes koeficienta testēšanas metode

Friction plays a critical role in the performance of paper and board in packaging, printing, and converting processes. The berzes koeficients (COF) affects how sheets feed through machinery, stack, and interact with surfaces. To ensure consistency, ISO 15359 provides a standardized horizontal plane method for measuring both berzes statiskie un kinētiskie koeficienti. For professionals involved in quality control or product development, understanding this method is essential to guarantee material behavior aligns with functional requirements.

Saņemt citātuISO 15359 Compliance Matters

Industries such as packaging, pharmaceuticals, and food rely heavily on material handling efficiency, where excessive or insufficient friction can lead to costly process disruptions. ISO 15359 ensures:

- Standardized testing conditions for inter-company comparisons.

- Reliable quality control through repeatable and objective measurements.

- Product safety and usability in downstream applications like form-fill-seal machines or automated packaging lines.

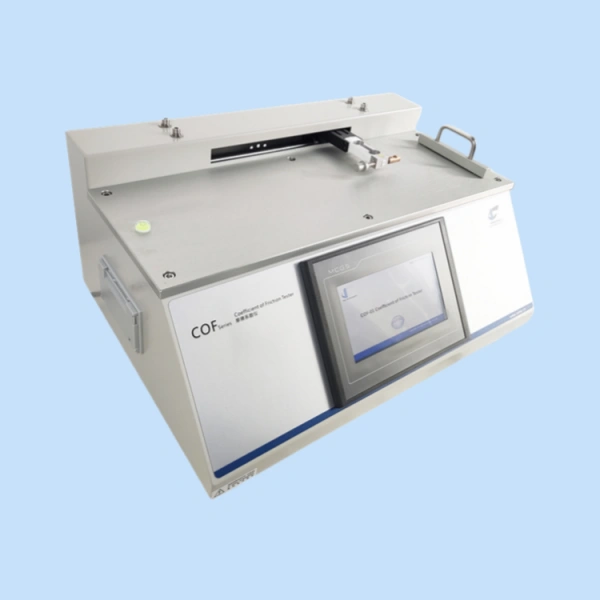

Cell Instruments’ COF-01 friction tester helps manufacturers achieve ISO 15359 compliance effortlessly, enabling robust QC systems and reducing the risk of packaging failure due to friction-related issues.

ISO 15359 Overview and Scope

ISO 15359, oficiālais nosaukums Paper and board — Determination of the static and kinetic coefficients of friction — Horizontal plane method, defines a reliable friction-testing method. This method is applicable to all types of paper and board and measures:

- The static coefficient of friction: resistance to initiating motion.

- The kinetic coefficient of friction: resistance to sustained motion.

The standard supports measurements before and after specified wear between two surfaces, ensuring results reflect real-world applications.

Coefficient of Friction Tester Requirements

To comply with ISO 15359, specialized equipment is required. The standard specifies a horizontal plane testing setup consisting of:

- A flat horizontal table made from incompressible material (e.g., metal, glass).

- A ragavas with standardized pressure (approx. 800g mass) to simulate contact force.

- A precīzijas slodzes kamera un data recorder for accurate force-time analysis.

- An elevator and drive mechanism for controlled sled movement.

- A guidance system to ensure parallel sled motion.

Cell Instruments piedāvā COF-01 berzes koeficienta testeris, fully compliant with ISO 15359. This model enables precise, repeatable measurement of both static and kinetic COFs, helping paper and board producers ensure material consistency.

Coefficient of Friction of Paper and Board: Key Considerations

When analyzing the papīra berzes koeficients, several critical factors influence results:

- Surface contamination: Even minor pollutants can drastically alter readings.

- Material orientation: Machine direction (MD) vs. cross direction (CD) affects slide behavior.

- Backing materials: Neoprene rubber backing ensures uniform pressure distribution.

- Test repeatability: ISO 15359 requires at least six valid measurements to ensure consistency.

The coefficient of friction of board is especially important in packaging applications, where heavier materials may introduce issues such as edge curl or pressure inconsistencies. Cell Instruments’ COF-01 tester allows configuration adjustments to accommodate board-specific challenges, supporting multi-layer board, corrugated sheet, and coated stock testing.

ISO 15359 Test Procedure in Practice

The ISO 15359 method involves the following procedural steps:

- Condition samples according to ISO 187.

- Prepare two pieces—one for the table, one for the sled—ensuring no contamination.

- Secure samples with proper orientation and apply the sled using an elevator.

- Measure:

- Static COF (μₛ) during the first motion initiation.

- Static and kinetic COFs at the third slide for wear-sensitive evaluation.

Precision and repeatability are critical. The COF-01 friction tester offers automated control for ramp time, speed, and sled positioning, minimizing human error and optimizing reproducibility.

https://youtu.be/0NyNZ_po80IChoosing the Right Coefficient Of Friction Tester

Designed for both R&D labs and production lines, un Šūnu instrumenti COF-01 tester supports:

- Paper and board testing per ISO 15359.

- Static and kinetic COF measurements with precision load cells.

- Touchscreen interface for easy operation and real-time data analysis.

- Adaptability for various sample types and configurations.

Backed by expert technical support and customization services, Cell Instruments empowers material professionals to enhance friction analysis while ensuring global standard compliance.

Sazinieties ar mums Iegūt berzes koeficienta testēšanas risinājumu

Accurate measurement of the coefficient of friction of paper and board is fundamental to performance in real-world applications. ISO 15359 offers a globally accepted framework, and with tools like the Cell Instruments COF-01 coefficient of friction tester, companies can maintain high product standards, streamline production, and ensure customer satisfaction.

By investing in ISO 15359-compliant equipment and processes, your organization ensures materials behave predictably in complex production environments, ultimately boosting reliability and efficiency.