Test ścierania tuszu

Metoda testowaniaDrukowane opakowania, etykiety i grafiki komercyjne są narażone na znaczne zużycie podczas przechowywania, wysyłki i obsługi. Zapewnienie ich trwałości wymaga niezawodnych metod oceny. Jedną z najbardziej uznanych technik jest test ścierania tuszu, jest znormalizowanym sposobem pomiaru odporności na ścieranie materiałów drukowanych. Niniejszy artykuł przedstawia test ścierania farby drukarskiej, wyjaśnia procedurę ASTM D5264 i podkreśla, w jaki sposób tester odporności na tarcie zapewnia spójne wyniki.

Dlaczego test rozcierania tuszu ma znaczenie w druku i pakowaniu?

Ścieranie jest jedną z najczęstszych przyczyn degradacji druku. Podczas transportu i użytkowania tarcie może powodować rozmazywanie, blaknięcie lub przenoszenie atramentu, prowadząc do:

- Zmniejszony wygląd i czytelność marki

- Niezadowolenie klienta z powodu złej prezentacji produktu

- Kwestie zgodności w branżach regulowanych, w których przejrzystość etykiet ma kluczowe znaczenie

Przeprowadzając Test odporności tuszu na ścieranie, Producenci mogą ocenić, czy ich materiały drukowane są w stanie wytrzymać te rzeczywiste warunki. Zapewnia to zarówno jakość produktu, jak i zaufanie konsumentów.

ASTM D5264 i jego rola w testowaniu odporności na ścieranie atramentu

Najczęściej cytowane wytyczne dotyczące tej oceny to ASTM D5264 - Standardowa praktyka w zakresie odporności na ścieranie materiałów drukowanych za pomocą testu Sutherland Rub Tester. Norma ta określa sposób pomiaru trwałości druku przy użyciu kontrolowanych cykli tarcia między próbką a powierzchnią receptora.

Kluczowe cechy normy ASTM D5264 obejmują:

- Konfiguracja testowa: Materiał drukowany jest montowany na gumowej podkładce, podczas gdy receptor jest przymocowany do obciążnika o masie 2 funtów (0,91 kg) lub 4 funtów (1,82 kg).

- Działanie: Receptor przesuwa się w przód i w tył nad wydrukiem, wykonując określoną liczbę ruchów. Każdy ruch to jeden pełny cykl.

- Ocena: Po teście wydruk jest sprawdzany pod kątem widocznej degradacji, a receptor jest analizowany pod kątem transferu atramentu.

- Aplikacje: Praktyka ta jest odpowiednia dla atramentów, powłok, laminatów i podłoży i może być dostosowana do badania efektów produktu, takich jak kontakt z detergentami lub żywnością.

Metoda ta zapewnia powtarzalny sposób porównywania odporności na ścieranie w kontrolowanych warunkach, umożliwiając zarówno nabywcom, jak i dostawcom uzgodnienie standardów wydajności.

Korzystanie z testera odporności na pocieranie w celu uzyskania spójnych wyników

Wykonywanie test ścierania tuszu nie jest praktyczne w nowoczesnych środowiskach produkcyjnych. A tester odporności na tarcie automatyzuje proces, zapewniając dokładność i powtarzalność. Przyrządy te odwzorowują ruch i ciśnienie zdefiniowane w normie ASTM D5264, umożliwiając jednocześnie elastyczną kontrolę parametrów.

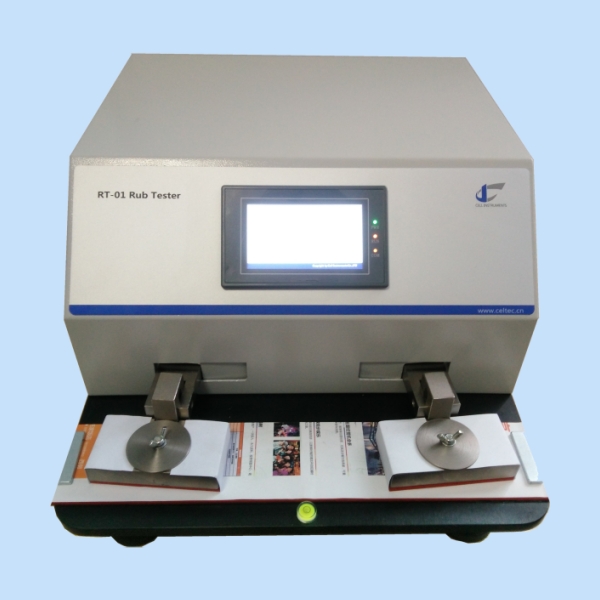

Na przykład Cell Instruments RT-01 Tester tarcia zapewnia:

- Regulowana prędkość od 20-120 cykli na minutę

- Możliwość wyboru przez użytkownika wagi 2 lb lub 4 lb

- Kontrola uderzeń i liczenie cykli za pomocą ekranu dotykowego

- Monitorowanie postępu testu w czasie rzeczywistym

- Opcjonalna podgrzewana płyta dla zaawansowanych potrzeb testowych

Symulując rzeczywiste warunki tarcia, RT-01 pomaga producentom określić, czy ich opakowania i etykiety mogą wytrzymać wymagające środowiska obsługi.

Aby uzyskać dokładne wyniki, laboratoria i producenci powinni:

- Używaj odpowiednio konserwowanych podkładek, wymieniając je, gdy się zużyją lub utlenią.

- Wybierz odpowiednią wagę w zależności od oczekiwanego stopnia ścierania.

- Przed badaniem upewnić się, że próbki i receptory są wolne od kurzu lub cząstek zewnętrznych.

- Porównanie wyników testów z normami referencyjnymi w celu zachowania spójności.

Zastosowania testu odporności na ścieranie atramentu

Test pocierania atramentem jest szeroko stosowany w różnych branżach, w tym:

- Opakowanie: Zapewnienie czytelności etykiet na opakowaniach żywności, napojów i produktów farmaceutycznych.

- Tekstylia i powłoki: Sprawdzanie trwałości nadruków na tkaninach lub powlekanych powierzchniach.

- Kleje i laminaty: Ocena odporności na ścieranie, gdy materiały warstwowe mogą się o siebie ocierać.

- Agencje kontroli jakości: Zapewnienie znormalizowanych, raportowalnych wyników audytów zgodności.