ASTM D642

Box Compression Test Method

When packaging is stacked or stored under heavy loads, its ability to resist compressive forces becomes a crucial factor in protecting contents. The ASTM D642 standard provides a clear method for evaluating the compressive resistance of shipping containers. This test is especially vital for manufacturers and quality control professionals in logistics, packaging, pharmaceuticals, and food industries.

What Is theASTM D642 Box Compression Test?

ASTM D642 என்பது Standard Test Method for Determining Compressive Resistance of Shipping Containers, Components, and Unit Loads. This method measures how well a packaging container withstands forces that compress it from the top, edges, or corners. It applies to individual boxes, complete unit loads, or packaging materials.

This method is widely used across industries such as e-commerce, food, beverage, and pharmaceuticals, where product integrity during storage and transportation is essential.

The test can be performed on containers with or without contents, providing flexibility for real-world testing scenarios.

Box Compression Test Standard and Its Importance

தி box compression test standard, as defined by ASTM D642, helps businesses determine if their packaging can endure the pressures of stacking, shipping, and long-term storage. The key parameters of this standard include:

- Top-to-bottom compression testing for realistic stacking load conditions.

- Edge-to-edge and corner-to-corner testing, especially useful for identifying weak points in packaging.

- Face-to-face compression tests using either fixed or swivel platen machines.

Meeting this standard is critical for minimizing product loss, reducing packaging failures, and ensuring compliance with industry regulations.

How to Conduct Carton Compression Test - ASTM D642

நடத்துதல் ஏ carton compression test involves a specific series of steps to ensure reliable and repeatable results:

1. Test Setup and Equipment

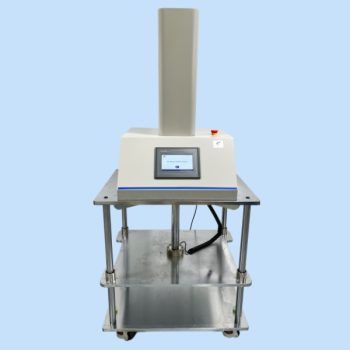

Use a compression testing machine with either fixed or swivel platens. The BCT-600 Box Compression Tester from Cell Instruments is highly recommended, as it supports multiple testing modes and complies fully with ASTM D642. It features a servo-driven platen for precise movement and customizable test conditions.

2. Specimen Preparation

Select complete cartons, ideally five or more for statistically significant results. Ensure they are either filled or empty depending on the testing purpose.

3. Specimen Orientation

Center the box correctly on the lower platen. Misalignment can lead to eccentric loading, affecting both test results and equipment safety.

4. Apply Pre-Load

Introduce an initial force:

- 50 lbf for single-wall corrugated boxes

- 100 lbf for double-wall

- 500 lbf for triple-wall

5. Compression Application

Load the specimen at a constant rate of 0.5 ± 0.1 in/min (12.7 ± 2.5 mm/min) until failure. Failure is typically defined as:

- A 10% drop from maximum load, or

- A deformation of ¾ inch (19 mm)

6. Data Recording

Use load-deformation recorders to monitor changes. If unavailable, record force values for every 0.1 in. of deformation manually.

Selecting the Right Equipment: Why Choose Cell Instruments’ BCT-600

For precise, reliable, and efficient carton compression testing, Cell Instruments’ BCT-600 Box Compression Tester is an ideal solution. It features:

- Three test modes: ultimate strength, fixed-value (load/deformation), and stacking simulation.

- 7” touchscreen interface for intuitive operation.

- Live data curves and customizable test programs.

- High-precision servo system for consistent loading speed.

This instrument not only meets ASTM D642 requirements but also supports advanced quality control and R&D in packaging development.

Choosing the Right Loop Tack Tester

For businesses involved in adhesive testing, investing in a high-quality loop tack tester is essential. The Cell Instruments Loop Tack Tester provides:

Precision measurement of tack force.

User-friendly operation with automated testing.

Reliable data for research and quality control.

Contact Us Get Loop Tack Testing Solution

தி ASTM D642 standard plays a critical role in verifying the structural integrity of packaging materials. Understanding how to perform a carton compression test according to this standard not only helps maintain quality but also supports innovation and safety in packaging design. For companies seeking accurate, standard-compliant testing solutions, Cell Instruments’ BCT-600 Box Compression Tester is a proven choice that enhances testing capability and confidence.

அடிக்கடி கேட்கப்படும் கேள்விகள்

It evaluates the compressive resistance of packaging containers to ensure they can withstand stacking and shipping loads without collapsing.

Yes. The standard allows for testing both filled and empty containers depending on the simulation needs.

Failure is typically defined as a 10% reduction in the maximum load or a deformation of ¾ inch (19 mm), as per ASTM D642.

A compression testing machine with fixed or swivel platens is required. The BCT-01 from Cell Instruments meets all necessary requirements.

Improper alignment can cause inaccurate results and may damage the test equipment. Ensuring proper placement ensures test validity and safety.