ASTM D882

TST-01 Testing Method

Tensile testing of thin plastic sheeting and films is critical for evaluating mechanical strength, elasticity, and performance under stress. The ASTM D882 standard defines a reliable procedure for measuring these properties. This article provides an in-depth overview of ASTM D882 and its application in plastic tensile strength test, film tensile strength, і heat seal strength evaluation—core performance indicators for manufacturers and quality control personnel across industries.

Understanding ASTM D882 and Its Purpose

The ASTM D882 standard outlines the test method for determining tensile properties of thin plastic sheeting. It focuses on evaluating tensile strength, modulus of elasticity, and elongation at break. This method is tailored for specimens with uniform cross-sections and is particularly relevant for materials under 1.0 mm in thickness, such as plastic films, flexible laminates, and barrier materials.

Tensile properties help manufacturers understand how their materials behave under tension, which directly impacts the packaging performance, seal integrity, and end-user satisfaction.

Relevance to Plastic Tensile Strength Test and Packaging Applications

The plastic tensile strength test is crucial in packaging, especially in determining how much force a plastic material can withstand before breaking. Using ASTM D882 ensures consistency and comparability across products and suppliers.

Key parameters assessed:

- Tensile Strength at Break (maximum force before failure)

- Elongation at Break (material stretch capacity)

- Tensile Modulus (stiffness of the material)

These parameters directly affect the performance of plastic packaging during sealing, shipping, and storage. For example, inadequate tensile strength may result in packaging failure during transit, while low elongation may cause brittleness and cracking.

Evaluating Film Tensile Strength for Flexible Packaging

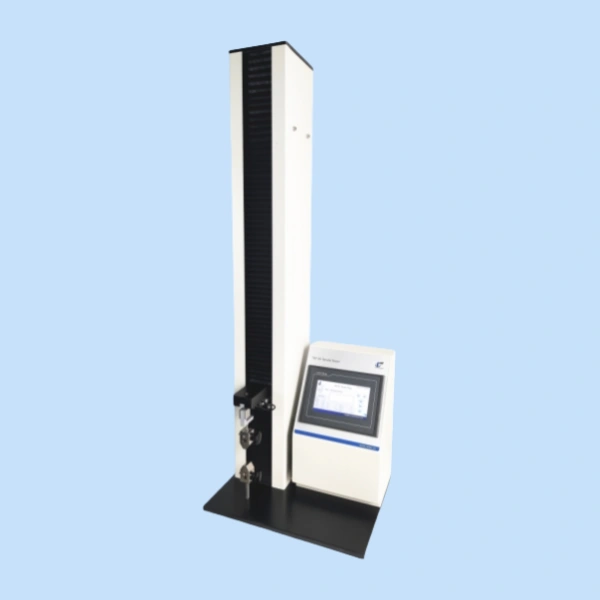

Film tensile strength refers to the maximum tensile load that a thin plastic film can bear. Under ASTM D882, films are tested using a constant rate of crosshead movement machine, like the Cell Instruments TST-01 Packaging Tensile Strength Tester, ensuring precise control over test parameters.

Important test setup elements include:

- Uniform specimen width (5–25.4 mm) and thickness

- Proper grip alignment to avoid slippage

- Crosshead separation rates based on initial strain rates

High film tensile strength is especially important for:

- Vacuum packaging

- Barrier films for medical and pharmaceutical products

- High-performance food packaging films

Using TST-01, quality control teams can quickly identify material inconsistencies, optimize supplier selection, and ensure compliance with industry specifications.

Heat Seal Strength and Its Connection to ASTM D882

Though ASTM D882 doesn’t directly measure heat seal strength, it complements heat seal tests by evaluating the mechanical integrity of the base film materials. If the base film lacks adequate tensile strength, the heat seal may rupture or delaminate under stress.

For products like sachets, pouches, and blister packs, evaluating both tensile and heat seal strength ensures holistic quality assurance. It also helps identify whether failures stem from sealing issues or material properties.

Advantages of Standardized Testing with ASTM D882

Applying the ASTM D882 test method provides:

- Reliable benchmarking across different film materials and suppliers

- Early defect detection in raw material quality

- Consistent material qualification for production runs

- Support for R&D and new material development

Combined with secondary tests such as ASTM F88 for seal strength, ASTM D882 enables a comprehensive assessment of packaging film performance.

Choosing the right Packaging Tensile Strength Tester

Стільникові інструменти’ TST-01 Вимірювач міцності на розрив упаковки is a precision instrument designed specifically for compliance with ASTM D882. It offers:

- High-accuracy force measurement

- Programmable grip separation speed

- Real-time data acquisition for stress-strain curves

- Compatibility with extensometers for modulus evaluation

This tester is ideal for applications requiring stringent evaluation of plastic films, laminates, and medical packaging materials. Additionally, it supports QC protocols in accordance with ISO and ASTM standards, enhancing regulatory compliance and customer confidence.

Contact Us Get Coefficient Of Friction Testing Solution

In today’s competitive packaging landscape, understanding the tensile performance of plastics and films is indispensable. The ASTM D882 standard remains the benchmark for such evaluations, ensuring accurate, repeatable, and meaningful data. By leveraging advanced testing systems like Cell Instruments' TST-01, manufacturers and quality control professionals can uphold the mechanical integrity and safety of their packaging solutions across various industries.

поширені запитання

ASTM D882 is designed for plastic films, sheeting, laminates, and other thin materials typically under 1.0 mm in thickness.

Not directly. However, it evaluates base material strength, which affects the overall seal strength. Use ASTM F88 for direct heat seal strength testing.

ASTM D882 is for thin films and sheeting, while ASTM D638 is used for thicker plastic specimens (often injection-molded).

Test speeds depend on the material’s elongation; however, a standard initial strain rate is used to calculate grip separation speed.