ASTM D624

Tear Strength Test Method

ASTM D624 plays a central role in evaluating the tear resistance of rubber and thermoplastic elastomers (TPEs). Industries using elastomeric materials—such as medical devices, packaging, automotive, consumer products, and electronic components—rely on this standard to assess how materials respond when cracks initiate and propagate under load. Because tears often start from small defects during service, understanding rubber tear strength is essential for ensuring durability and product safety.

This method details how to measure tearing behavior using a tensile testing machine and defines several specimen geometries, each designed to capture specific failure modes.

Získat nabídkuRubber Tear Strength and Its Importance

The rubber tear strength property indicates how effectively a material resists the initiation or propagation of a tear. While tensile strength measures overall stretching capability, tear strength focuses on real-world failure modes. Sharp edges, cyclic loading, abrasion, or embedded particles often produce localized stresses that make tearing the most common damage mechanism in service.

Several factors influence tear performance, including stress distribution, strain rate, sample geometry, and the presence of notches. ASTM D624 provides a controlled and repeatable method to quantify these effects, enabling engineers and QC professionals to make reliable comparisons.

Tear Strength Test Standard Requirements

The tear strength test standard specifies procedures for preparing samples, conditioning them, and applying a steadily increasing load until complete rupture occurs. A tensile tester pulls the specimen at a defined crosshead speed. The recorded force—per unit thickness—represents the tear strength.

According to the standard:

- Type A, B, and C samples use 500 ± 50 mm/min separation speed.

- Type T and CP samples use 50 ± 5 mm/min speed.

- Correct specimen alignment ensures uniform strain and prevents grip slippage.

- Test results from different geometries are not interchangeable because each design characterizes a different tear mechanism.

These distinctions allow users to tailor testing to specific product conditions.

ASTM D624 Type A, Type B, Type C, Type T, and Type CP

ASTM D624 includes several specimen types, each capturing a different failure behavior. These variations align closely with diverse elastomer applications.

ASTM D624 Type A – Crescent for Smaller Samples

ASTM D624 Type A resembles Type B, but without the extended tab ends. Laboratories use Type A when working with smaller molded components or limited material quantities. It also measures tear propagation but may exhibit slightly different stress distribution due to its shorter gauge length.

ASTM D624 Type B – Crescent With Tabs

ASTM D624 Type B is one of the most commonly preferred geometries. It features a razor-nicked crescent with extended tabs that improve gripping stability. This type measures tear propagation strength, making it ideal for general rubber quality control. Manufacturers often choose Type B when the original sheet is large enough to prepare the required dimensions.

ASTM D624 Type C – 90-Degree Apex Specimen

ASTM D624 Type C has a distinct 90-degree angle without a notch. The stress concentration at the apex helps evaluate tear initiation strength, which is critical when assessing failure from sharp corners or embedded flaws. If the tear does not initiate at the apex, the results may resemble tensile strength, so correct sample preparation is essential.

ASTM D624 Type T – Trouser Tear Specimen

ASTM D624 Type T consists of a split-leg geometry resembling a trouser shape. It measures tear propagation along the sample’s length. Type T is widely used for flexible elastomeric films, thin sheets, and soft TPE compounds.

ASTM D624 Type CP – Constrained Path Tear

ASTM D624 Type CP is a modification of Type T. It uses a constrained tear path and thicker legs to ensure the tear remains aligned, making it especially suitable for materials prone to deviation or excessive stretching. This leads to more stable and repeatable propagation results.

Choosing the Right Tearing Strength Tester

Selecting an appropriate tearing strength tester ensures accurate and consistent results. The tester must maintain stable crosshead speeds, provide sensitive force measurement, and support various grip configurations.

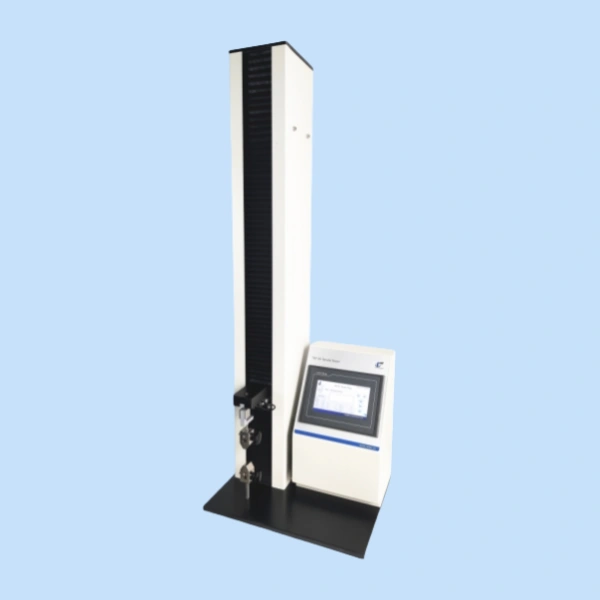

The Cell Instruments TST-01 Zkoušečka pevnosti v tahu is an excellent choice for ASTM D624 testing due to its:

- Precision load cell and high sampling rate

- Stable crosshead motion for both high-speed and low-speed tear tests

- Compatibility with Type A, B, C, T, and CP fixtures

- Adaptability for both R&D and routine quality inspection

Its ability to switch between different tear modes allows laboratories to complete the full range of ASTM D624 testing with one device.

Contact Us Get ASTM D624 Testing Solution

ASTM D624 provides a comprehensive framework for evaluating tear behavior in rubber and TPE products. Its multiple specimen types allow users to capture tear initiation and propagation across different applications. By using reliable instruments such as the Zkoušečka tahu TST-01, laboratories can achieve consistent, accurate, and repeatable results that enhance product quality and strengthen material engineering decisions. For manufacturers and quality personnel seeking dependable tear evaluation, ASTM D624 remains an indispensable standard.