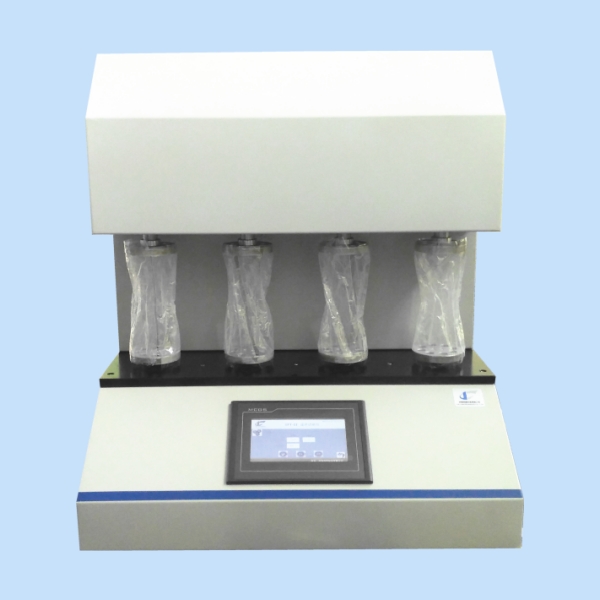

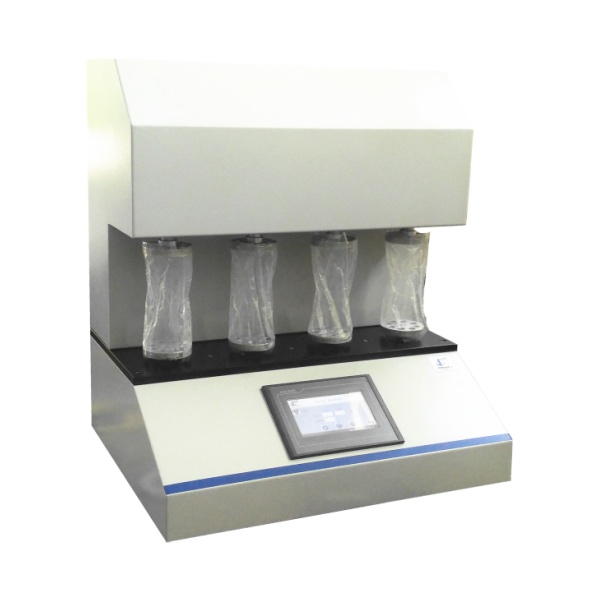

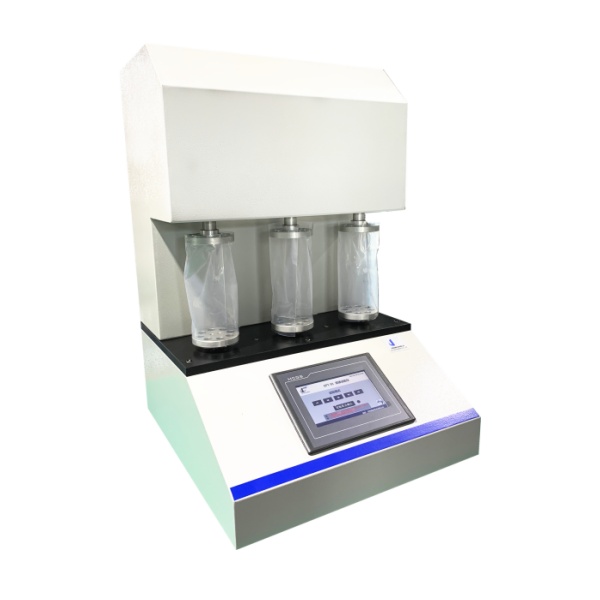

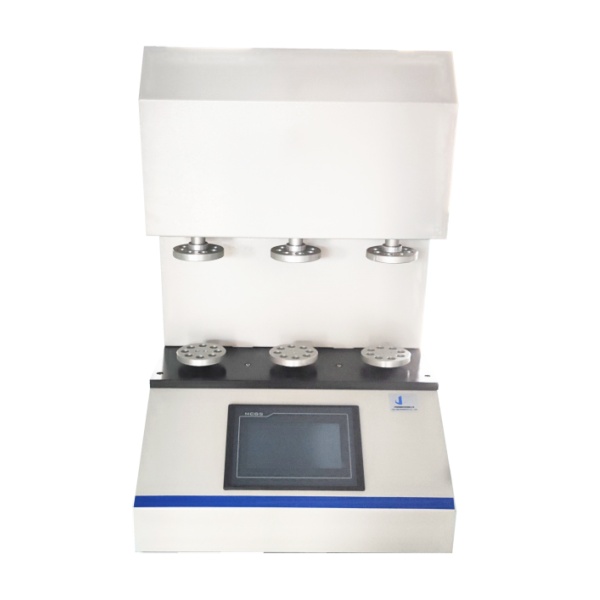

GFT Gelbo Flex Tester

- Standard: ASTM F392

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

Introduction of Gelbo Flex Tester

The Gelbo Flex Tester is a specialized instrument designed to evaluate the flex durability and mechanical integrity of flexible materials such as barrier films, laminates, and coated fabrics. By simulating real-world twisting and compressive deformation, this tester provides critical insights into the resistance of packaging and coated materials to pinhole formation, cracking, and barrier property degradation. Standards such as ASTM F392 and ISO 7854 define the testing methods that ensure accuracy, repeatability, and international comparability.

The Gelbo Flex Tester, sometimes referred to as a rumple flex tester or flex tester, operates by subjecting test specimens to simultaneous twisting and compressing motions. This combined action reproduces the mechanical stress flexible packaging materials experience during filling, sealing, transportation, and storage.

The test method, commonly known as the Gelbo test method, evaluates a material’s ability to maintain integrity under cyclic deformation. Materials that fail this test often develop microscopic pinholes or cracks that compromise the package’s barrier performance against oxygen, moisture, or gas transmission.

Principle of the Gelbo Flex and Related Standards

Two primary international standards govern flex durability evaluation: ASTM F392 and ISO 7854.

ASTM F392, titled Standard Practice for Conditioning Flexible Barrier Materials for Flex Durability, specifies test conditions for assessing the resistance of flexible packaging materials to flex-induced pinholes and barrier failures. In this method, specimens undergo repeated flexing at 45 cycles per minute, involving a 440° twist combined with a 65 mm horizontal motion. The test is conducted under standard conditions of 23 ± 2°C and 50 ± 5% relative humidity. Depending on the desired conditioning level, test cycles may range from 20 to 2700, corresponding to levels A through E.

ISO 7854, Rubber- or plastics-coated fabrics — Determination of resistance to damage by flexing, defines three methods of flex testing. Method C, known as the crumple/flex method, closely resembles the Gelbo principle. Here, a cylindrical specimen is subjected to oscillating twist and axial compression, simulating real-life flex stress for coated fabrics, medical materials, and technical textiles.

Together, these standards establish the Gelbo flex procedure as the global benchmark for flex durability testing.

How the Gelbo Flex Tester Works

The Gelbo Flex Tester (for example, the GFT Flex Durability Tester by Cell Instruments) operates with high precision to replicate ASTM and ISO flexing motions.

- Sample Preparation: Standard samples are 200 × 280 mm, cut in both machine and transverse directions.

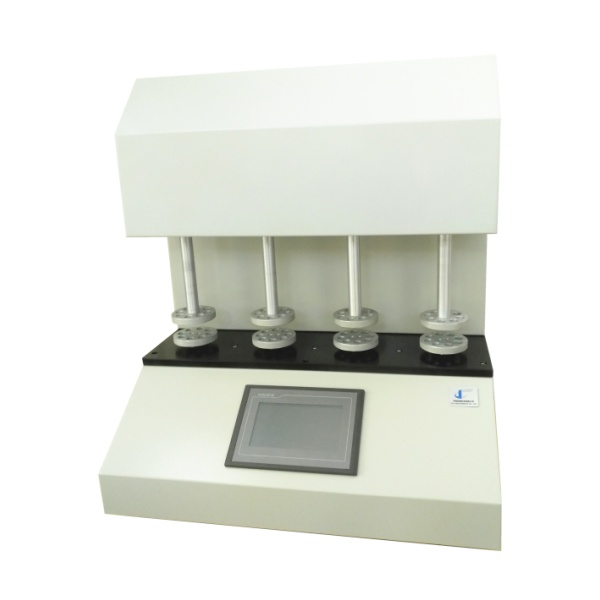

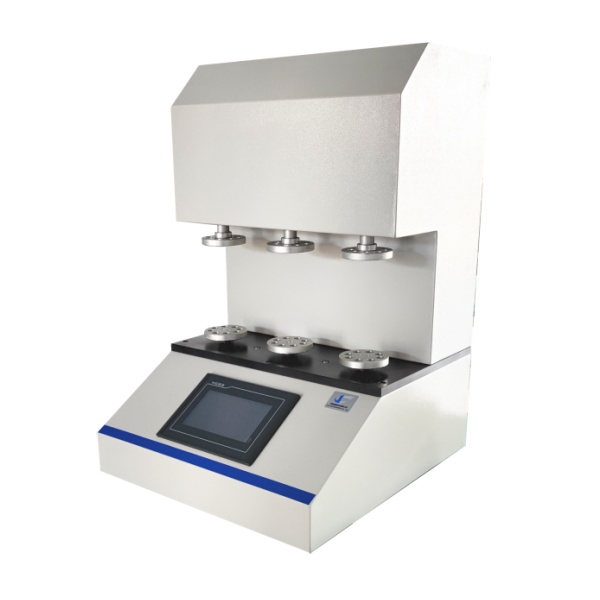

- Mounting: Samples are clamped or adhered to the tester’s mandrels, forming a cylindrical shape for simultaneous twisting and compression.

- Flexing Cycle: The tester executes a 440° twist during the first 90 mm of stroke, followed by a 65 mm linear compression, at a consistent 45 cycles per minute.

- Mode Selection: Users can select from five programmable test modes (A–E) to suit different material types or test objectives.

- Result Evaluation: After conditioning, specimens are inspected for pinholes, cracks, or barrier degradation using OTR (Oxygen Transmission Rate), WVTR (Water Vapor Transmission Rate), or GTR tests.

This controlled process allows laboratories and quality control teams to quantify a material’s flex resistance and predict its performance under real-world mechanical stress.

Key Features and Main Parameter

The GFT Gelbo Flex Tester series from Cell Instruments offers advanced technology designed for high precision and ease of use:

- PLC Control & Touchscreen Interface – Ensures accurate motion control, user-friendly operation, and data repeatability.

- Multiple Test Stations – Available with three or four stations for parallel testing and comparative analysis.

- Programmable Test Conditions – Supports ASTM F392 modes A–E for versatile testing from quick screening (20 cycles) to endurance evaluation (2700 cycles).

- Durable Mechanical Design – Engineered for long-term stability and compliance with ASTM F392 and ISO 7854 standards.

- Enhanced Data Reliability – Supports post-test evaluation of barrier integrity, pinhole formation, and mechanical strength changes.

| GFT Gelbo Flex Durability Tester | ||

| Parameter | GFT-02 Model | GFT-01 Model |

| Flex Angle | 440° (90 mm) or 400° (80 mm) | |

| Capacity | 3.5 N.m | 2.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm | |

| Stations | 3 | 4 |

| Sample Size | 280 mm x 200 mm | |

| Power | 110~220V | |

Applications of Gelbo Flex Testing

Gelbo flex testing is essential in industries where flexible materials must retain barrier integrity and aesthetic quality after repeated handling or mechanical stress. Key application areas include:

- Flexible Packaging for food, pharmaceuticals, and medical devices

- Coated Fabrics and Films for industrial, textile, and outdoor uses

- Adhesive Laminates and composite structures

- Quality Control in R&D laboratories and certification agencies

By identifying weak points early, manufacturers can improve material formulation, coating technology, and lamination processes.

FAQs

A: Cell Instruments’ Gelbo Flex Tester boasts a unique blend of precision engineering and innovative design features. From its intuitive user interface to its advanced automation capabilities, every aspect is meticulously crafted to optimize performance and user experience. Additionally, its compatibility across a wide range of materials and industries sets it apart as a versatile solution for flex testing needs.

A: By subjecting materials to rigorous flex testing, the flex durability tester helps identify weaknesses and potential failure points early in the development process. This proactive approach enables manufacturers to address issues before they escalate, resulting in products that are more resilient, reliable, and ultimately, of higher quality.

A: Absolutely! The Gelbo Flex Tester is designed to accommodate a wide range of sample sizes and shapes, offering flexibility and versatility in testing. Whether you’re working with small, delicate films or larger, bulkier materials, our tester can adapt to meet your specific testing requirements with ease.

A: Precision is paramount with the flex durability tester. Through meticulous calibration and robust construction, we ensure that each test yields consistent, dependable results. Additionally, our tester is designed to minimize external factors that could influence test outcomes, further enhancing accuracy and repeatability.

A: At Cell Instruments, we prioritize customer satisfaction and support. Our dedicated technical support team is available to assist users with any questions, concerns, or technical challenges they may encounter. Whether you need assistance with setup, calibration, or troubleshooting, our experts are here to provide prompt and effective support to ensure your testing processes run smoothly

Reference

ASTM F392 Standard Practice for Conditioning Flexible Barrier Materials for Flex Durability