ISO 9895

Short Span Compression Tester method

In the field of paper and board performance evaluation, ISO 9895 plays a pivotal role in determining compressive strength using a precise method known as the short-span compression test. For packaging, containerboard, and structural paper products, this standard enables reliable assessment of material resistance under compression.

Understanding the SCT Test and Its Industrial Importance

The SCT test, or short-span compression test, is essential for evaluating the in-plane compressive strength of paper and board materials. It simulates the stresses encountered during stacking, loading, and packaging applications—particularly in corrugated board manufacturing.

The ISO 9895 method uses a short span compression tester to clamp a 15 mm wide test strip with a span of only 0.7 mm between the jaws. The clamps then compress the specimen until it buckles or fails, measuring the maximum force applied. This value is used to compute compressive strength in kilonewtons per meter (kN/m), providing critical information for boxboard producers and packaging engineers.

This test is especially suitable for papers with a grammage range of 100 to 400 g/m², commonly found in containerboard, kraft liner, and fluting applications. Manufacturers often prefer the SCT test over other methods due to its low span and strong correlation to box compression strength (BCT).

Key Parameters in ISO 9895 Testing

ISO 9895 outlines strict test conditions and apparatus requirements to ensure consistency and accuracy:

- Clamp width: 30 mm

- Clamping force: 2,300 ± 500 N

- Span between clamps: 0.70 mm ± 0.05 mm

- Compression speed: 3 mm/min ± 1 mm/min

- Precision: ±1% error within 10–100% of the full-scale range

Measurement accuracy and consistent sample preparation are critical. Conditioning according to ISO 187 and grammage determination per ISO 536 are required before testing.

Advantages of the Short Span Compression Tester in Paper Testing

Utilizing a short span compression tester brings multiple benefits:

- Quick and accurate testing with minimal specimen preparation

- Strong correlation to end-use performance, especially in corrugated and folded boxes

- High repeatability and reproducibility, essential for QA/QC operations

- Sensitive detection of subtle differences in machine direction (MD) and cross direction (CD) strength properties

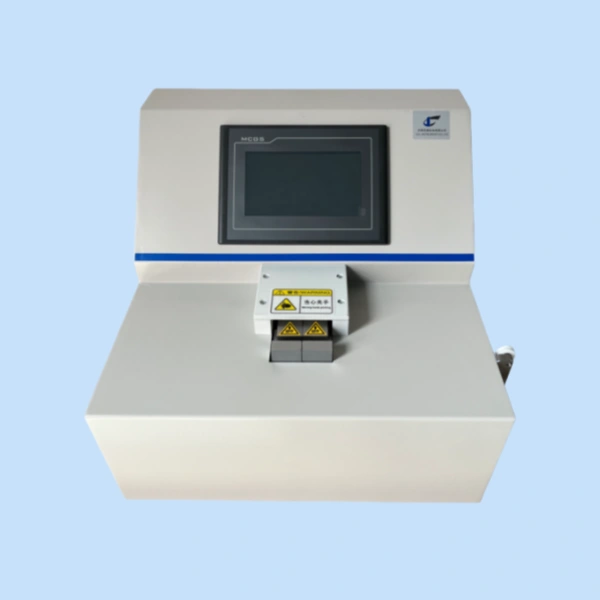

The Cell Instruments SCT-01 Short Span Compression Tester is engineered to fully comply with ISO 9895 and includes precision clamping mechanics, stable jaw alignment, and an intelligent control interface to ensure repeatable and standardized SCT test results.

Applications of Board Short Span Test in Quality Control

The board short span test is integral to the quality assurance of various industries:

- Corrugated board production: to predict box strength under stacking loads

- Paper mills: for MD and CD strength assessment of liner and fluting

- Packaging converters: to verify material suitability for heavy-duty packaging

- Regulatory compliance: to meet ISO and customer specifications

Its compact testing area and short span configuration make it particularly responsive to changes in fiber orientation, bonding quality, and refining conditions during production.

Paper Short Span Test vs. Traditional Compression Testing

Traditional compression tests (like ring crush or edge crush) often fail to isolate intrinsic sheet properties. The paper short span test, however, focuses purely on material compression within a small span—minimizing bending or buckling effects.

This specificity allows manufacturers to:

- Optimize fiber selection and furnish composition

- Evaluate refining or wet-end chemistry effects

- Detect mechanical or chemical inconsistencies in production

Selecting the Right Instrument: Short Span Compression Tester

For producers seeking high accuracy and compliance with ISO 9895, the Cell Instruments SCT-01 offers:

- Fully automated operation with intuitive interface

- Precision-aligned clamps with minimal deviation

- Real-time force display and high-resolution data acquisition

- Easy calibration with traceable standards

- Robust mechanics ensuring years of consistent performance

By integrating this tester into routine lab workflows, quality control teams can ensure better control over product performance, reduce variability, and meet global customer demands.

Contact Us Get ISO 9895 Testing Solution

ISO 9895 offers a critical method for determining the compressive strength of paper and board using the short span compression test. Whether you’re in packaging, converting, or papermaking, this standard delivers insights into your material’s strength characteristics in both machine and cross directions.

To perform SCT tests with the highest accuracy and repeatability, we recommend the SCT-01 Short Span Compression Tester by Cell Instruments—your reliable partner for board and paper compression strength analysis.

FAQs

ISO 9895 specifies a method for measuring compressive strength in paper and board using the short-span compression test, vital for quality control in packaging and boxboard production.

A 15 mm wide paper strip is compressed across a 0.7 mm span until it buckles. The maximum force is recorded and used to calculate compressive strength.

Because it closely reflects the stacking strength of corrugated containers and helps manufacturers control material strength efficiently.

The standard applies to papers and boards with a grammage between 100 and 400 g/m².