burst strength test of flexible pack

Why Use ASTM F2054 for Flexible Pack Seal Integrity?

The ASTM F2054 burst test uses internal air pressurization within restraining plates to simulate real-world mechanical stresses. As pressure builds inside the package, the test identifies the weakest point—typically the seal—and records the pressure at which the package bursts. This value provides a direct indicator of the seal’s burst strength and offers insight into production consistency or potential process deviations.

This method is especially useful for high-integrity packaging such as:

- Medical device pouches

- Sterilized pharmaceutical packaging

- Flexible food pouches

- Single-use sachets and unit-dose packaging

These applications require seals to resist pressure variations during autoclaving, transport, or end-user handling.

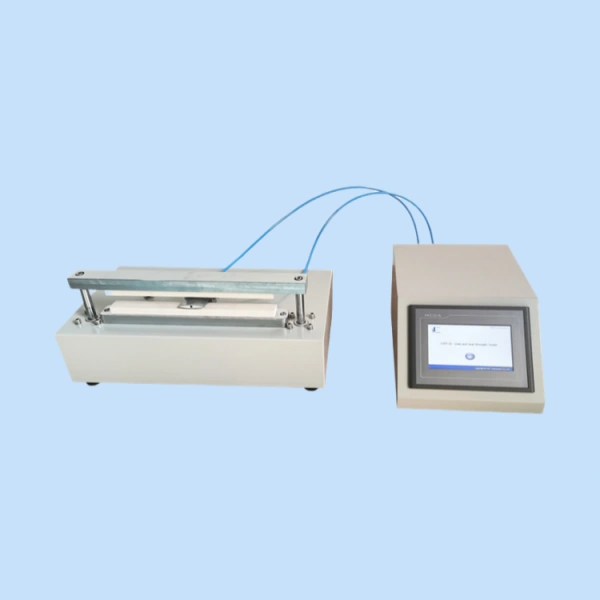

Pouch Burst Tester and Restraining Plates

The ASTM F2054 method specifies two main equipment configurations:

- Open-package testers: Used for pouches with one unsealed side, often during manufacturing stages.

- Closed-package testers: Used for completely sealed pouches. These testers insert a sensor and nozzle through a puncture to deliver pressurized air.

In both configurations, restraining plates prevent package expansion and isolate the seal perimeter as the failure point. The burst strength test of flexible pack relies heavily on proper test conditions—plate rigidity, air flow control, and sensor sensitivity—to ensure accurate results.

Significance and Application in Flexible Pack

Understanding burst strength is vital for packaging engineers and QA professionals. This test helps:

- Ensure regulatory compliance for medical and pharmaceutical packaging.

- Палепшыць product shelf life by identifying poor seal zones.

- Detect material weaknesses or seal integrity issues introduced during process changes.

- Compare supplier material performance.

The burst pressure test standard does not assess total package integrity or seal uniformity but can be combined with methods such as ASTM F88 (seal strength test) or ASTM F1140 (unrestrained burst testing) for a comprehensive evaluation.

Key Parameters in Burst Strength Test of Flexible Pack

Critical parameters for repeatable results include:

- Type and size of the package

- Configuration of seals (3-side or 4-side seal)

- Air flow rate and pressure increase control

- Sensor calibration and response time

- Distance and rigidity of restraining plates

For best results, test specimens must be conditioned for at least 72 hours under standard atmospheric conditions (as per ASTM E171). Failure to standardize conditions can significantly affect burst pressure readings.

Burst Strength Test Procedure Simplified

- Prepare the sample – either with or without contents, ensuring it fits between restraining plates.

- Insert the pressurization nozzle (through the open end or via puncture).

- Seal the package (in open configuration) or connect airtight mechanisms (in closed configuration).

- Pressurize at a controlled rate.

- Monitor for a rapid pressure drop indicating seal rupture.

- Record the burst pressure and observe the failure point.

Advantages of Burst Strength Test in Flexible Packaging

- Fast and objective measurement of seal performance

- High repeatability with standardized test setup

- Applicable to a wide range of flexible film materials

- Valuable during R&D, process optimization, і production quality checks

Choosing the Right Burst Tester

For labs and manufacturers looking for compliance with ASTM F2054, Cell Instruments' pouch burst tester offers precision, automation, and adaptability. It supports both open and closed package testing, with configurable pressure rates and integrated data recording—ideal for regulated industries such as pharma, food, і medical packaging.

Features include:

- Accurate internal pressure measurement in kPa or psi

- Customizable plate gap settings for various pouch sizes

- Test repeatability and high-resolution sensors

- Intuitive control interface and PC connectivity

Contact Us Get Burst Strength Testing Solution

The ASTM F2054 burst test method is a vital tool in evaluating seal strength in flexible packaging. Whether you’re producing sterilizable medical pouches or retort food sachets, consistent burst strength ensures packaging safety, compliance, and performance. When paired with a reliable pouch burst tester, such as the one provided by Клеткавыя інструменты, manufacturers can confidently monitor and optimize their seal integrity.