ISO 5628 Guide with Bending Stiffness Testing Machine Insights

The bending stiffness test is a critical material property evaluation method used across industries including packaging, medical devices, pharmaceuticals, textiles, and paperboard production. This test measures a material’s resistance to bending and provides insights into its rigidity, flexibility, and structural performance. ISO 5628:2019 outlines standardized principles for executing such tests using two-point, three-point, or four-point bending methods.

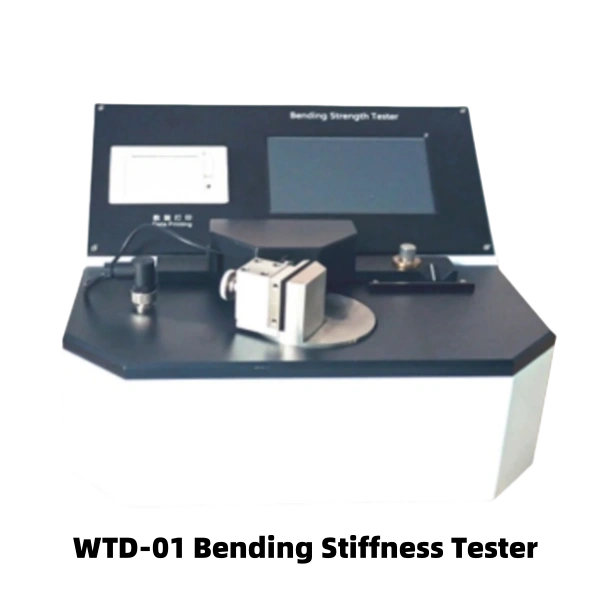

To ensure accurate results, manufacturers and quality control professionals must follow the correct procedures, use compliant equipment, and understand how variables like material thickness, modulus of elasticity, and support conditions affect results. This article guides you through the proper execution of the bending stiffness test while recommending reliable instrumentation such as the Cell Instruments WTD-01 Bending Stiffness Tester.

Stiffness Test Method Overview Based on ISO 5628

The stiffness test method described in ISO 5628 is grounded in beam theory, where the bending stiffness (Sb) of a homogeneous sample is determined by:

Sb = (E × I) / b

Where:

- E is the elastic modulus of the material

- I is the second moment of inertia

- b is the width of the specimen

According to ISO 5628:2019, stiffness can be calculated using three approaches:

- Measuring the maximum slope of the force vs. deflection or force vs. angle curve.

- Applying a fixed deflection/angle and measuring the corresponding force after a specified time.

- Applying a constant force and recording the deflection or angle after a fixed period.

Each method must be executed under well-defined conditions, with testing rate and measurement timing reported clearly.

Equipment Selection: Use of a Stiffness Testing Machine

Choosing a suitable stiffness testing machine is essential for accurate results and compliance with ISO standards. Key specifications include:

- Adjustable bending length with ±1% precision

- Ability to record force versus deflection or force versus angular deflection

- Sensitivity within ±2.5% of the full measurement range

- Stable supporting anvils that minimize testing artifacts

The Cell Instruments WTD-01 Bending Stiffness Tester fully meets these requirements. It provides automated, precise data collection and curve analysis across all ISO 5628-approved testing configurations. It’s a robust solution for laboratories aiming to ensure product performance through reliable stiffness data.

Sample Preparation and Testing Conditions

Sampling 1

For batch analysis, select specimens according to ISO 186. Ensure test pieces are representative of the lot to ensure valid conclusions.

Conditioning 2

Condition specimens as per ISO 187 at standard temperature and humidity. Retain specimens in this environment during the entire testing process.

Test Piece Preparation 3

- Cut test pieces from undamaged sheets

- Avoid watermarks, wrinkles, or folds

- Ensure long edges are parallel within ±1%

- Prepare a minimum of 10 specimens for each direction (machine direction and cross direction)

The definition of the “upper side” of the test piece is critical, as bending must be performed in both directions (upwards and downwards), and results averaged to eliminate curvature bias.

Testing Procedure

Before conducting the bending stiffness test, determine thickness using ISO 534 (for paper and board) or ISO 3034 (for corrugated board). Note that bulk thickness and sheet thickness yield different results and must be handled accordingly.

- Place the sample on the stiffness tester

- Conduct five tests bending towards the upper side and five towards the lower side

- Plot force vs. deflection or force vs. angle

- Use the linear portion of the curve for stiffness evaluation

- Average all test results and report using three significant figures

Important: Ensure that each specimen is as flat as possible to avoid errors from pre-curvature.

Evaluation and Calculation

Results can be calculated by either:

- Using the linear region of the force-deflection/angle curve

- Applying the recommended deflection or angle and measuring the force

- Recording the maximum force and the corresponding deflection

Choose the evaluation method based on your test configuration (two-point, three-point, or four-point) and ensure that data is averaged across all valid test pieces.

Why Choose Cell Instruments Bending Stiffness Testing

For manufacturers and QC labs seeking efficiency and ISO compliance, the Cell Instruments WTD-01 Bending Stiffness Tester offers:

- Full compatibility with ISO 5628 test procedures

- High precision and consistent data outputs

- Multi-point testing capability

- User-friendly interface for simplified operation

- Suitable for a wide range of materials including paperboard, flexible packaging, and medical laminates

This instrument is ideal for packaging manufacturers, medical device developers, and material testing labs who need reliable bending stiffness test results under ISO-regulated conditions.

Conclusion

Executing a bending stiffness test in compliance with ISO 5628:2019 requires more than just measuring force and deflection—it demands thoughtful sample preparation, accurate instrumentation, and careful calculation. Selecting a capable stiffness testing machine, like the Cell Instruments WTD-01, ensures reliable results and supports rigorous quality control.

By adhering to the methods and principles outlined here, professionals in packaging, medical, pharmaceutical, and related sectors can confidently assess material performance and uphold product standards.