تحسين جودة التعبئة والتغليف باستخدام معدات اختبار الصلابة

In today’s manufacturing and logistics environments, stiffness testing equipment plays a critical role in evaluating material rigidity and performance. Whether in the packaging sector, the courier industry, or the medical and food industries, understanding a material’s stiffness ensures that it meets required strength, durability, and handling standards.

With increasing pressure on packaging materials to be lightweight yet strong, testing paper strength is more crucial than ever. Accurate stiffness testing not only ensures compliance with international standards like ISO 5628 و TAPPI T556 but also enhances overall product reliability, efficiency, and consumer experience.

Applications and Benefits of Stiffness Testing Equipment

Modern stiffness testing equipment is designed to measure the resistance of materials to bending or deformation under a defined load. This property directly influences a material’s suitability for:

- Folding cartons and corrugated boxes

- Medical blister packaging and pharmaceutical leaflets

- Textiles, flexible films, and laminates

- Food and daily chemical product packaging

- Mailers, envelopes, and inserts used in the courier industry

Advantages of stiffness testing include:

- Better control of packaging formability

- Accurate prediction of material behavior in high-speed packing lines

- Optimization of print performance and product protection

- Reduced material waste and improved sustainability

Through precise data collection, manufacturers and QA professionals can refine formulations, adjust production processes, and reduce costly performance failures.

Testing Paper Strength in the Courier Industry

Among the key applications, testing paper strength stands out in the courier industry, where packaging must endure mechanical shock, stacking pressure, and frequent handling. Courier bags, boxes, flyers, and liners must retain form without tearing or collapsing.

Stiffness directly influences:

- Load-bearing capacity during transit

- Ease of insertion and sealing in automation systems

- Shelf and warehouse stacking stability

Inadequate stiffness can lead to damaged goods, customer complaints, and increased returns — all of which result in financial and brand losses. With stiffness testing equipment, courier packaging manufacturers can validate that their paper and board meet the required resistance thresholds for real-world logistics.

Why Choose Cell Instruments’ Stiffness Testing Equipment

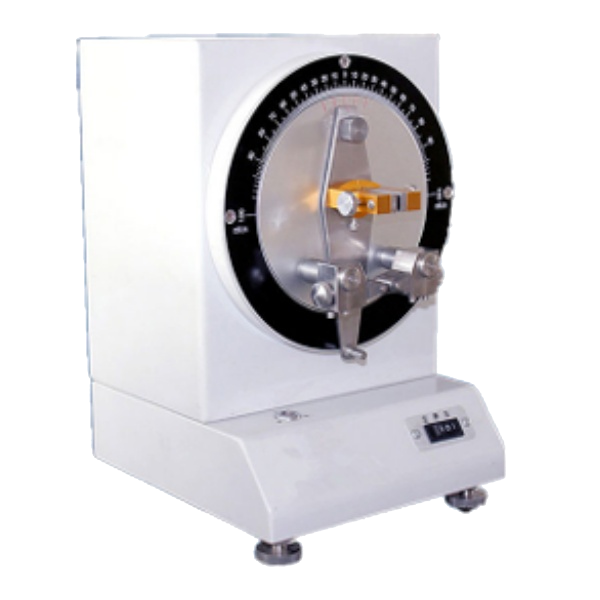

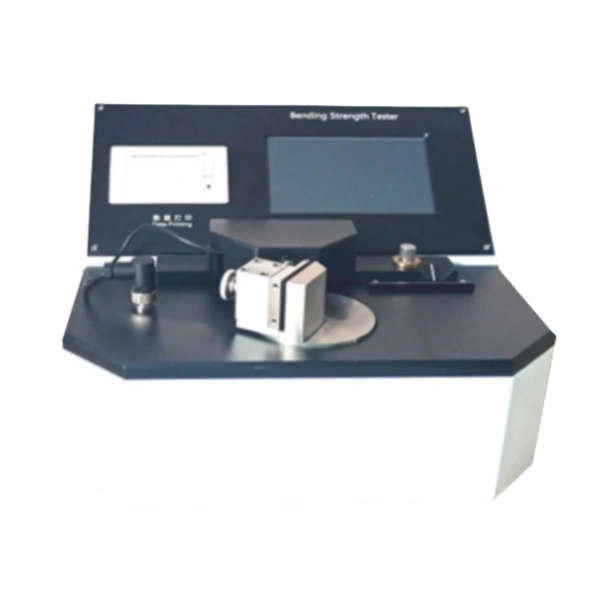

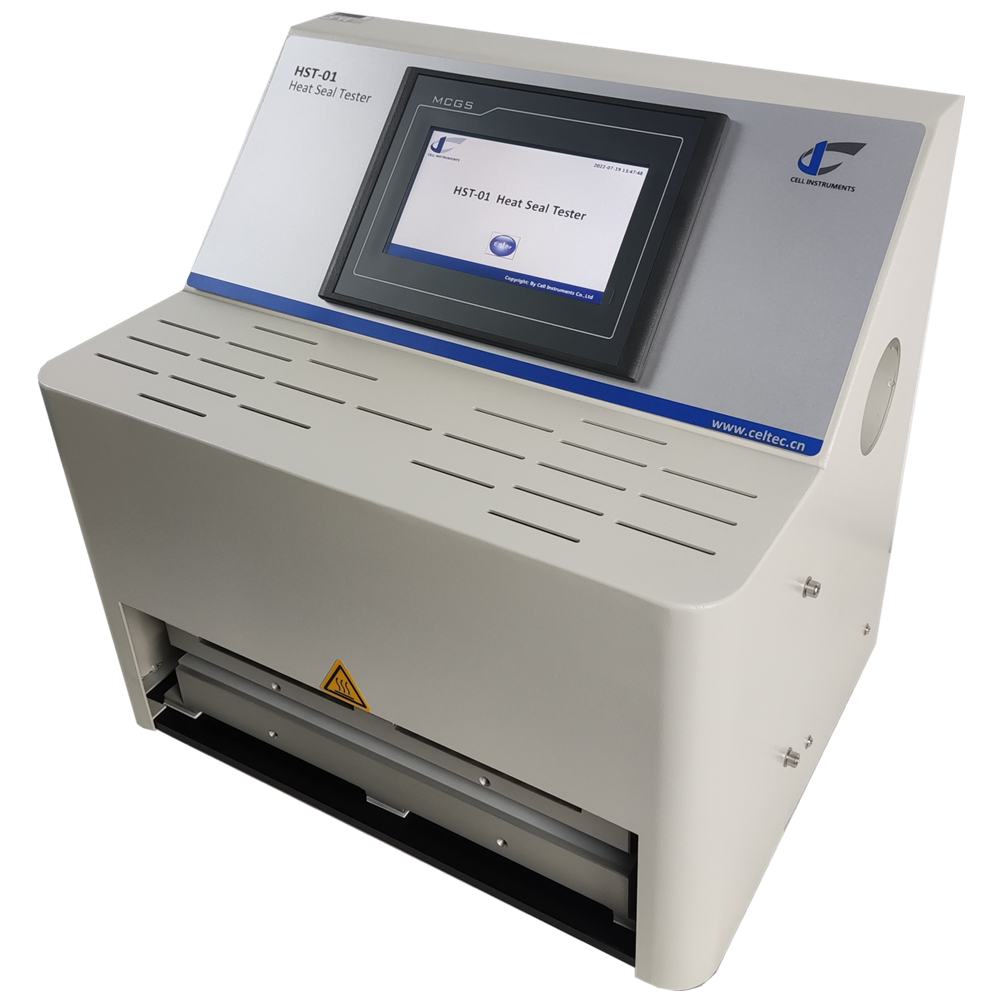

أدوات الخلية offers a high-performance stiffness tester designed for precision, repeatability, and versatility across a broad range of materials. Key features include:

- Full compliance with ISO 5628 and other relevant standards

- Adjustable test angles and force ranges, covering both light and heavy-duty materials

- High-resolution sensors for consistent data output

- User-friendly software with data export and curve visualization

These capabilities make it ideal for packaging converters, R&D laboratories, third-party testing agencies, and logistics companies. More importantly, Cell Instruments can customize stiffness testing systems to meet specific requirements, including integration into automated testing environments.

Expanding Applications Across Industries

Although commonly used in the courier industry, stiffness testing equipment also adds value in:

- المستحضرات الصيدلانية – ensuring inserts and cartons are easy to handle yet protective

- Textile testing – evaluating the drape and touch feel of fabrics

- الالكترونيات – ensuring rigid packaging protects delicate contents

- المأكولات والمشروبات – optimizing pouch or tray stiffness for sealing and stacking

No matter the sector, stiffness is a measurable indicator of functional performance, user experience، و supply chain compatibility.

Upgrade Your Packaging with Reliable Stiffness Data

In competitive markets, material stiffness often determines the success of a package, product, or delivery. Investing in the right stiffness testing equipment helps manufacturers validate quality, meet regulatory standards, and protect brand reputation.

With Cell Instruments’ stiffness tester, you gain the ability to perform professional-grade evaluations backed by global standards and decades of materials testing expertise. Contact us today to learn how our solutions can support your product development and quality assurance goals.