ASTM D5264

Rub Resistance Test Method

When printed packaging, labels, or coatings face friction during shipping, handling, or use, their visual appeal and legibility can degrade. To assess this durability, ASTM D5264 provides a standardized method for evaluating the abrasion resistance of printed materials using the Sutherland Rub Tester. This guide walks you through the rub resistance test procedure, explains the significance of the method, and introduces the right equipment to ensure accurate and reproducible results. For professionals in quality control, packaging, pharmaceuticals, printing, and materials testing, mastering this standard is crucial to ensuring product integrity.

Understanding ASTM D5264 and Its Importance

ASTM D5264 is the standard practice used to determine the abrasion resistance of printed substrates by simulating repeated rubbing or contact under controlled lab conditions. The test helps compare how well different inks, coatings, or substrates hold up to mechanical wear—especially important in high-contact environments such as retail packaging, medical labeling, and food containers.

Friction-induced print degradation or ink transfer can compromise product appearance and regulatory compliance. With ASTM D5264, manufacturers and buyers alike gain a consistent method to test abrasion durability.

Rub Test for Printing: When and Why to Use It

The rub test for printing is essential when evaluating:

- Printed cartons and folding boxes for consumer goods

- Labels on pharmaceutical and food packaging

- Ink or coating adhesion on flexible packaging and films

- Instructional print durability on medical devices

Common causes of damage during shipping and storage—such as stacking, vibration, and environmental stress—can be replicated in this controlled test environment.

Rub Resistance Test Procedure - ASTM D5264

The rub resistance test procedure involves applying a weighted block (typically 2 lb or 4 lb) on a mounted sample and rubbing it against a receptor material for a predefined number of cycles (called strokes). Below is a step-by-step overview:

1. Specimen Preparation

- Cut test samples to 76 × 152 mm (3 × 6 in.)

- Ensure even ink coverage and uniform substrate surface

- Condition specimens at 23 ± 1°C and 50 ± 2% RH

2. Apparatus Setup

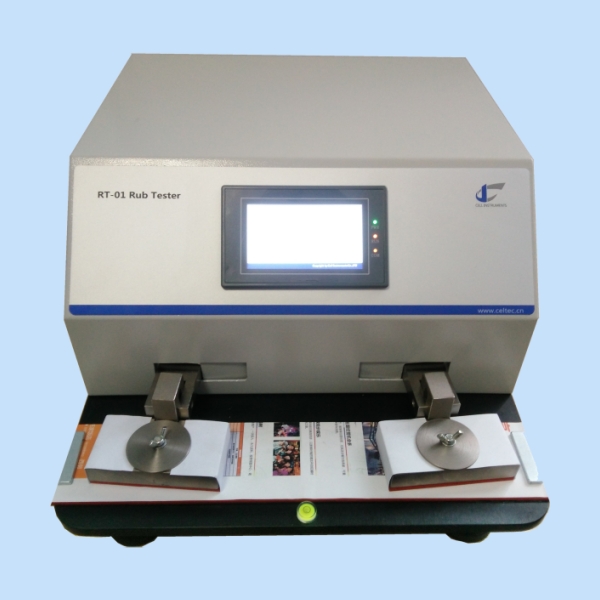

- Place a Sutherland Rub Tester or equivalent (like Cell Instruments RT-01) on a stable surface in a controlled room

- Install rubber pads on both the test base and receptor block

- Attach the receptor material to the weight with clamps or pressure-sensitive tape

3. Mounting the Specimens

- Fix the test specimen face-up on the rubber pad on the base

- Install the receptor block over it

- Brush both surfaces with an anti-static brush to remove debris

4. Test Execution

- Set the number of strokes (a back-and-forth rub counts as one)

- Start the tester—movement will proceed in a 57 mm arc until completion

- Common tests range from 10 to 100 strokes, depending on application severity

5. Evaluation

- Check the specimen for visible wear or print degradation

- Inspect the receptor for ink transfer

- Compare results to a control standard or acceptance criteria

Note: Excessive rubbing may generate heat and distort test accuracy, so avoid over-testing.

Choosing the Right Loop Tack Tester

For laboratories and factories needing precision rub testing, the RT-01 Rub Tester from Cell Instruments is a smart investment. Conforming to ASTM D5264 and other international standards, this device ensures stable, repeatable results across:

- Dry rub and wet rub scenarios

- Functional rub (actual use conditions)

- Variable speed and stroke settings

- Double test stations for higher efficiency

The RT-01’s PLC control and touchscreen interface make operation simple, while its precision arc ensures accurate measurement of rub resistance for labels, films, cartons, and printed sheets. It’s ideal for R&D labs, production floors, and third-party inspection agencies.

Contact Us Get Rub Testing Solution

The ASTM D5264 rub resistance test offers a standardized, effective way to determine how well printed surfaces withstand abrasion. By following the detailed rub resistance test procedure and using reliable instruments like the RT-01 Rub Tester from Cell Instruments, quality control teams can ensure their printed materials meet durability requirements across a wide range of industries.

FAQs

It evaluates how well printed materials resist abrasion and wear, helping determine their durability during shipping and use.

Printed labels, packaging films, cartons, flexible packaging, coatings, and paper products are commonly tested.

It depends on the application, but tests usually range from 10 to 100 strokes, adjustable based on severity.

ASTM D5264 specifies 2 lb or 4 lb weights, selected based on the application’s abrasion exposure level.

It complies with ASTM D5264, offers versatile rub test modes, precise control, and high repeatability—ideal for R&D and QC applications.