PSTC 16

Pressure Sensitive Tape Loop Tack Test

Pressure-sensitive tapes are integral in many industries, and their performance is heavily influenced by the adhesive properties they possess. One key metric used to assess these properties is loop tack, which measures the immediate adhesion of the tape to a surface. To ensure quality control and consistent results, industry professionals rely on the PSTC 16 loop tack test.

Understanding PSTC 16 and Loop Tack Testing

What is PSCT 16?

PSTC 16 is a standard published by the Pressure Sensitive Tape Council (PSTC) that outlines the procedures for measuring the loop tack of pressure-sensitive adhesives. This test evaluates the ability of the adhesive to adhere to a surface under immediate pressure, a crucial factor in determining how well the tape will perform under normal conditions. The loop tack test is a fundamental part of quality assurance for manufacturers of pressure-sensitive tapes, ensuring they meet performance expectations.

What Is the Loop Tack Test?

Loop tack refers to the force required to separate an adhesive from a substrate immediately after contact. Unlike peel or shear strength, tack measures the instantaneous bond formation capability of the adhesive. The pressure sensitive tape loop tack test simulates real-world scenarios where tapes must adhere swiftly with minimal pressure.

PSCT 16 Loop Tack Test Method

PSTC 16 outlines two distinct methods for performing the loop tack test: Test Method A and Test Method B. Both methods involve forming a loop of adhesive tape, bringing it into contact with a stainless steel panel, and measuring the separation force. The key difference between these methods lies in the testing equipment.

Test Method A

Uses a tensile tester with a 175 mm specimen

In Test Method A, technicians utilize a tensile tester to measure the force required to detach the loop of tape from a surface. This method is precise but can require more setup and calibration.

Test Method B

Employs a dedicated loop tack tester with a 125 mm specimen

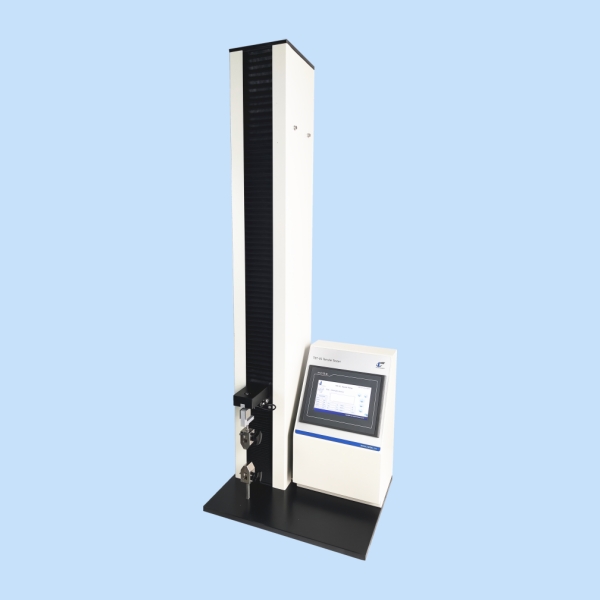

Test Method B, on the other hand, uses a specialized loop tack tester, such as the LTT-01 from Cell Instruments. This method provides a more straightforward and automated approach, delivering consistent results with minimal operator input. The LTT-01 is specifically designed to meet the requirements of PSTC 16, ensuring compliance with industry standards.

Test Method A vs. Test Method B

While both methods evaluate loop tack, their equipment and specimen requirements differ:

| Aspect | Test Method A | Test Method B |

|---|---|---|

| Specimen Length | 175 mm (7 inches) | 125 mm (5 inches) |

| Equipment | Tensile Tester | Loop Tack Tester |

| Contact Area | 625 mm² (1 in²) | 625 mm² (1 in²) |

| Applications | Research & Developmenct | Quality Control & Production |

Test Method B is often preferred for routine testing due to its specialized design, which minimizes variability and accelerates workflows.

Procedure Highlights for PSTC 16 Testing

- Sample Preparation

- Cut specimens to the required dimensions (24 mm width).

- Condition samples at 23°C ±2°C and 50% ±5% relative humidity for 24 hours.

- Testing Procedure

- Clean the stainless steel panel to remove residue.

- Form the tape into a loop (adhesive facing outward).

- Bring the loop into contact with the panel using controlled force.

- Measure the maximum force required to separate the adhesive.

- Failure Modes

- Adhesive Failure: Separation at the adhesive-substrate interface.

- Cohesive Failure: Internal splitting within the adhesive layer.

- Adhesive Transfer: Residual adhesive remains on the substrate.

Choosing the Right Equipment for PSTC 16 Compliance

For accurate and repeatable results, selecting a loop tack tester designed for PSTC 16 is essential. The Cell Instruments LTT-01 Loop Tack Tester offers:

- 7-Inch Touch Screen: Simplifies parameter adjustments and data visualization.

- PLC Control & Precision Ball Screw: Ensures consistent test speeds (1–500 mm/min) and displacements.

- Customizable Parameters: Adjust dwell time, stroke, and speed to match PSTC 16 requirements.

- Compliant Test Panels: Includes float glass or stainless steel panels for Method A or B.

- Enhanced Safety: Automatic return and limit devices.

- Data Accuracy: Microprinter and software integration for traceable reports.

This instrument not only streamlines compliance with PSTC 16 but also supports FINAT FTM-9 and ASTM D6195 standards, making it a versatile choice for labs and production facilities.

Key Considerations for Loop Tack Testing

When performing loop tack testing under PSTC 16, there are several factors to keep in mind:

- Surface Preparation: The condition of the substrate can impact test results. Ensure that the surface is clean and free from contaminants.

- Tape Type: Different tapes may exhibit varying loop tack values. Choose the appropriate settings on the tester to match the tape’s specifications.

- Environmental Conditions: Temperature and humidity can influence the performance of pressure-sensitive tapes. Conduct tests in a controlled environment for the best results.

By using equipment like the LTT-01, manufacturers can easily control these variables and ensure consistent, reliable testing results.

Contact Us Get Loop Tack Testing Solution

PSTC 16 is a fundamental standard for evaluating pressure-sensitive adhesives using the loop tack test method. By following proper procedures and using a loop tack tester, manufacturers can ensure high-quality adhesive performance. For advanced testing solutions, Cell Instruments’ Loop Tack Tester is an industry-leading choice.