Needle Penetration Test Guide for Medical Device and Packaging Testing

Needle penetration test plays a critical role in evaluating the mechanical performance of hypodermic needles, prefilled syringes, and rubber closures. This test ensures that needles possess sufficient sharpness and that closures offer proper penetrability while maintaining sealing integrity. For manufacturers and quality control professionals, understanding this test is essential for compliance with international standards such as ISO 11040-4, ISO 7864, En ISO 8871-5.

Penetrability Test and Needle Sharpness Testing Overview

Penetrability test, needle sharpness testing, En penetrability test for rubber stoppers are essential evaluations in the pharmaceutical and medical device industry. These assessments ensure ease of injection, minimize patient discomfort, and verify the functionality of closure systems.

According to ISO 8871-5, the penetrability is defined as the force required to pierce an elastomeric closure with a needle. In parallel, ISO 7864 and ISO 11040-4 define the penetration force and drag force required to pass a needle through a standard substrate or foil.

Test Principles and Objectives

De needle penetration test aims to measure:

- De initiële penetratiekracht (or piercing force) when the needle tip contacts the substrate.

- De cutting and drag forces as the needle shaft advances.

- The consistency of performance across multiple samples.

This test is not only crucial for needle sharpness testing, but also verifies the penetrability of rubber stoppers used in sterile containers.

Test Standards and Applicability

The test is primarily conducted according to the following international standards:

- ISO 11040-4: Prefilled syringes — covers complete systems including glass or plastic barrels.

- ISO 7864: Hypodermic needles — provides guidance on peak force and drag analysis during needle insertion.

- ISO 8871-5: Elastomeric closures for vials — evaluates penetrability, fragmentation, and self-sealing performance.

The test applies to:

- Staked needles or attached needles

- Rubber stoppers

- Prefilled syringes and sterile subassemblies

- Quality assurance of raw materials and finished products

Equipment and Setup Requirements

A compliant needle penetration test requires:

1. Universal Testing Machine

- Load cell capacity: up to 10 N (or appropriate for test range)

- Speed control: typically between 20 mm/min and 200 mm/min, commonly 100 mm/min

- Sampling rate: 500 Hz for peak force accuracy

2. Needle Holder

Designed to ensure vertical alignment and precise control of insertion path.

3. Test Substrate

- Foils for ISO 11040-4 method

- Synthetic elastomers such as:

- Latex rubber (40±5 Shore A, 1.0 mm thickness)

- Polyurethane (85±10 Shore A, 0.40 mm thickness)

- Silicone rubber or LDPE film as per ISO 7864 guidelines

4. Substrate Holder

Should maintain consistent clamping force and expose a 10 mm circular penetration area

Detailed Test Procedure

- Prepare the test specimen: Fix a fresh section of foil or elastomer in the substrate holder without tension.

- Mount the needle: Secure the test needle perpendicular to the test surface using a calibrated holder.

- Set the machine: Apply motion at a constant speed (commonly 100 mm/min).

- Penetrate and record:

- Measure the peak force (F0) for the needle tip

- Log cutting force (F1) En heel force (F2)

- Measure drag force (F3) for full shaft penetration

- Retract needle: Complete the cycle and use a new site for each sample.

- Data analysis: Generate force vs. displacement curve, calculate mean and standard deviation for peak and drag forces.

Test Report and Quality Documentation

A complete report for the needle penetration test moet het volgende bevatten:

- Substrate specification and condition

- Needle specifications (diameter, type, treatment)

- Speed and test method

- Penetration and drag force results

- Sample size and statistical evaluation

- Observations or deviations

Application and Benefits in Quality Control

For pharmaceutical manufacturers, compliance with these tests supports:

- Regulatory submissions (e.g., FDA, EMA)

- Product safety and consistency

- Improved user experience in parenteral delivery

- Reduced injection pain and patient discomfort

To enhance the accuracy and reproducibility of the penetratietest, advanced instrumentation is essential.

Choosing the Right Bloom Tester

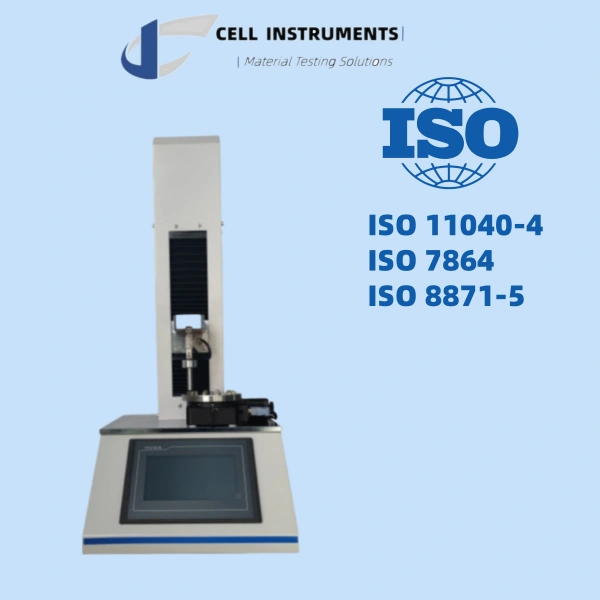

Celinstrumenten offers a high-precision needle penetration tester, specifically designed to meet the requirements of ISO 11040-4, ISO 7864, En ISO 8871-5. Our system supports:

- Multi-speed programmable control

- High-resolution force sensors

- Easy sample mounting and alignment

- Compatible with multiple needle and substrate types

By choosing Cell Instruments, you ensure compliant, repeatable, and efficient testing in line with global quality standards.

Contact Us Get Bloom Testing Solution

De needle penetration test is vital for validating the functionality and safety of injection systems and rubber closures. It directly affects user comfort, product integrity, and regulatory approval. By applying standardized procedures and using advanced testing systems like those offered by Celinstrumenten, manufacturers can confidently ensure product reliability and compliance.