ISO 9626

Test rurki igłowej ze stali nierdzewnej

ISO 9626 to międzynarodowy standard, który definiuje właściwości mechaniczne i wymiary wymagania dotyczące sztywności Rurki igielitowe ze stali nierdzewnej używany w urządzenia medycznew tym strzykawek i igieł podskórnych. Ponieważ testowanie igieł do strzykawek odgrywa kluczową rolę w zapewnieniu bezpieczeństwa i funkcjonalności, zrozumienie i stosowanie normy ISO 9626 pomaga producentom spełniać wymogi prawne, jednocześnie dostarczając niezawodne komponenty medyczne.

Uzyskaj wycenęCo to jest ISO 9626?

Zapewnia znormalizowane specyfikacje dla rurek ze stali nierdzewnej stosowanych w produkcji igieł medycznych, w zakresie od 3,4 mm (10 Gauge) do 0,18 mm (34 Gauge). Norma ma zastosowanie wyłącznie do sztywnych rurek, z wyłączeniem wariantów elastycznych ze względu na różne właściwości mechaniczne.

Kluczowe obszary objęte normą ISO 9626 obejmują:

- Tolerancje wymiarowe rurki igielitowej ze stali nierdzewnej

- Właściwości mechaniczne, takie jak sztywność i odporność na pękanie

- Odporność na korozję w symulowanych warunkach fizjologicznych

- Przygotowanie i ocena ekstraktów do testów biokompatybilności

Standard ten jest niezbędny dla producentów igieł do iniekcji, pobierania próbek płynów i innych zastosowań medycznych. Jego przestrzeganie zapewnia spójność działania, bezpieczeństwo pacjentów i zgodność z globalnymi organami regulacyjnymi.

Testowanie igły strzykawkowej zgodnie z normą ISO 9626

Norma ISO 9626 określa kilka kluczowych procedur testowania igieł strzykawkowych, które weryfikują integralność mechaniczną i trwałość rurek igieł:

Test sztywności igły wtryskowej

Ten test ocenia sztywność rurki igłowej pod kontrolowanym obciążeniem. Procedura obejmuje:

- Wspieranie rury na rozpiętości określonej przez jej skrajnię

- Przyłożenie siły skierowanej w dół za pomocą tłoka o określonej geometrii

- Pomiar ugięcia w środku w celu oceny sztywności

Nadmierna elastyczność może skutkować nieprawidłową obsługą lub niedokładnymi wstrzyknięciami. Producenci muszą zapewnić, że igła zachowuje stabilność mechaniczną w oczekiwanych warunkach klinicznych.

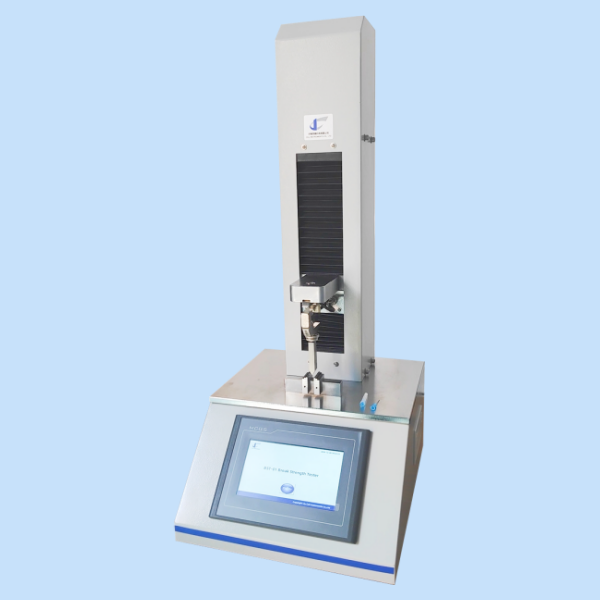

Tester sztywności rur igłowych Cell Instruments TS-01 jest zoptymalizowany pod kątem tego zastosowania. Oferuje on:

- Dokładność siły ±0,1 N

- Pomiar odchylenia na poziomie mikronów

- Konfigurowalne ustawienia zakresu według specyfikacji miernika

Test odporności na złamanie igły

Odporność na złamanie jest niezbędna, aby zapobiec uszkodzeniu rurki podczas użytkowania. Norma ISO 9626 zaleca cykliczny test zginania, w którym rura poddawana jest do 20 naprzemiennym zgięciom pod określonym kątem:

- Rury o regularnych ściankach: (25 ±1)°

- Rury cienkościenne: (20 ±1)°

- Bardzo cienkie/ultracienkie ścianki: (15 ±1)°

Test pomaga ocenić odporność na zmęczenie materiału przy powtarzającym się obciążeniu. Widoczne pęknięcie oznacza awarię.

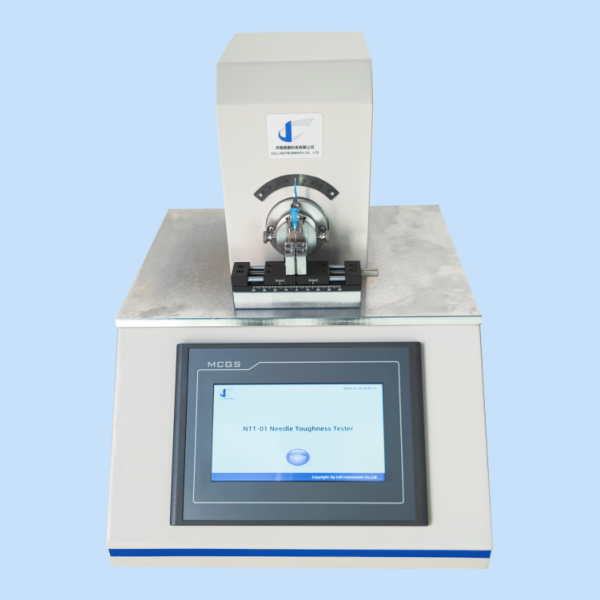

Cell Instruments' NTT-01 Needle Tubing Resistance Tester wykonuje ten test za pomocą:

- Programowalne kąty i cykle gięcia

- Oprzyrządowanie do kontroli wizualnej

- Regulowany zacisk dla różnych średnic rur

Ocena odporności na korozję

Załącznik D do normy ISO 9626 dotyczy odporności na korozję, zapewniając, że igły nie ulegają degradacji w kontakcie z płynami ustrojowymi. Rurki ze stali nierdzewnej muszą być odporne na powstawanie wżerów i rdzy po zanurzeniu w roztworach testowych, takich jak sól fizjologiczna.

Chociaż nie zawsze jest to obowiązkowe, wielu producentów uwzględnia odporność na korozję jako część rutynowego testowania igieł strzykawek w celu ograniczenia ryzyka.

Dodatkowe kwestie związane z testowaniem ISO 9626

Oprócz podstawowych ocen mechanicznych, norma ISO 9626 wymaga również:

- Precyzyjne pomiary wymiarów

- Identyfikacja typu ściany (RW, TW, ETW, UTW)

- Klasyfikacja stopów według ISO 15510 lub ASTM A959

- Dokumentacja testowa zawierająca rozmiar miernika, wartości ugięcia i warunki testowe

Dokładne testy nie tylko spełniają wymogi zgodności, ale także wzmacniają niezawodność produktu i reputację marki.

ISO 9626 Testing – Essential for Syringe Quality Control

Niespełnienie norm ISO 9626 może prowadzić do:

- Wygięcie lub złamanie igły podczas wstrzyknięcia

- Niespójne dostarczanie płynów

- Zwiększone ryzyko obrażeń pacjenta

- Niezgodność z przepisami i wycofywanie produktów

Dzięki integracji testów igieł strzykawkowych zgodnych z normą ISO 9626, producenci i zespoły ds. zapewnienia jakości:

- Weryfikacja wytrzymałości mechanicznej i trwałości

- Zapewnienie zgodności z wymogami prawnymi

- Zmniejszenie odpowiedzialności i liczby awarii produktów

- Zwiększenie zaufania i satysfakcji klientów

Wybór rozwiązania testowego ISO 9626

TS-01 Tester sztywności igły strzykawki

Aby dokładnie ocenić charakterystykę sztywności rurek igły ze stali nierdzewnej zgodnie z normą ISO 9626 załącznik B, tester sztywności igły strzykawki TS-01 firmy Cell Instruments zapewnia niezawodne i precyzyjne rozwiązanie. Przyrząd ten zapewnia spójne przyłożenie siły i dokładny pomiar ugięcia rurki, pomagając producentom i zespołom kontroli jakości spełnić oczekiwania regulacyjne dotyczące testowania sztywności igieł iniekcyjnych.

NTT-01 Tester odporności na złamanie igły

Tester odporności na złamanie igły NTT-01 jest niezbędnym narzędziem do oceny wytrzymałości mechanicznej rurek igieł medycznych pod wpływem powtarzających się sił zginających zgodnie z normą ISO 9626 załącznik C. Zaprojektowany z myślą o rygorystycznych środowiskach zapewniania jakości, tester ten symuluje rzeczywiste warunki użytkowania i dostarcza precyzyjnych danych na temat odporności rurek i integralności strukturalnej - co ma kluczowe znaczenie dla zapobiegania awariom igieł podczas zastosowań klinicznych.

Skontaktuj się z nami, aby uzyskać rozwiązanie testowe ISO 9626

ISO 9626 odgrywa kluczową rolę w Testowanie igieł do strzykawek ustalając poziomy odniesienia dla sztywność, odporność na pękanie i ogólna integralność strukturalna rurek igłowych ze stali nierdzewnej. Dzięki precyzyjnym ocenom mechanicznym producenci mogą zapewnić, że ich produkty spełniają zarówno oczekiwania prawne, jak i funkcjonalne.

Testery TS-01 i NTT-01 firmy Cell Instruments oferują kompleksowe, zgodne z normami ISO rozwiązanie spełniające zmieniające się wymagania kontroli jakości urządzeń medycznych. Zainwestuj w lepszą zgodność, zmniejszone ryzyko i doskonałą wydajność z Cell Instruments jako partnerem w testowaniu igieł strzykawkowych.

Często zadawane pytania

1. Jaki jest główny cel normy ISO 9626?Norma ISO 9626 określa wymagania wymiarowe i mechaniczne dla sztywnych rurek igłowych ze stali nierdzewnej stosowanych w urządzeniach medycznych w celu zapewnienia bezpieczeństwa i wydajności.

2. Jakie rodzaje testów są objęte normą ISO 9626?Testy obejmują sztywność igły iniekcyjnej, odporność na złamanie igły, odporność na korozję i przygotowanie ekstraktu do oceny biokompatybilności.

3. Jakie są typy przewodów RW, TW, ETW i UTW?Odnoszą się one do kategorii grubości ścianek: Regular Wall (RW), Thin Wall (TW), Extra-Thin Wall (ETW) i Ultra-Thin Wall (UTW), które określają parametry testu i kąty gięcia.

4. W jaki sposób sprzęt Cell Instruments może pomóc w testach ISO 9626?Cell Instruments TS-01 i NTT-01 zapewniają dokładne, powtarzalne warunki testowania sztywności i odporności na pękanie, pomagając producentom zachować zgodność z normami ISO 9626.

5. Dlaczego testowanie odporności na złamanie igły jest ważne?Gwarantuje to, że igła nie złamie się pod wpływem naprężeń podczas użytkowania, zapobiegając awarii urządzenia i urazom pacjenta.